The Architecture, Engineering, and Construction (AEC) industry is undergoing a significant transformation, driven by the increasing adoption of digital technologies. Scan to BIM automation is at forefront of this revolution, offering unprecedented precision and efficiency in creating digital representations of physical structures. As the global construction output is projected to grow substantially by 2030, the integration of AI, automation, and cloud-based workflows into Scan to BIM processes is becoming crucial for firms aiming to stay competitive and enhance sustainability. This article delves into the intricacies of Scan to BIM automation, exploring its benefits, future trends, and the challenges that lie ahead.

What is Scan to BIM Automation?

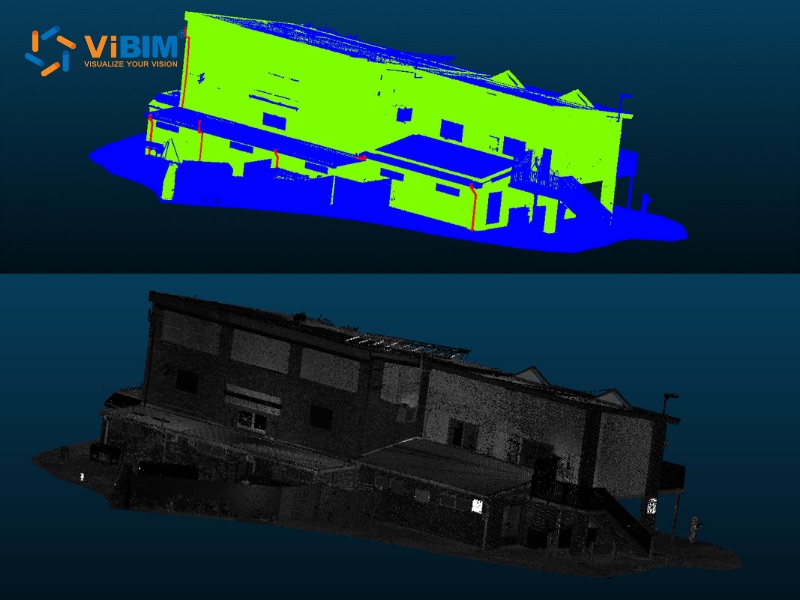

Scan to BIM is the process of capturing the as-built conditions of a physical space or structure using 3D laser scanning or photogrammetry and then converting this data into an accurate, intelligent BIM model. Scan to BIM automation refers to the use of advanced technologies, particularly artificial intelligence (AI) and machine learning, to speed up and simplify the conversion of raw scan data into structured BIM elements (walls, floors, doors, windows, pipes, etc.). This focuses on automatically identifying, classifying, and generating BIM elements from scan data, significantly reducing manual effort and speeding up the creation of accurate as-built models for design, renovation, and facility management.

Benefits of Scan to BIM Automation

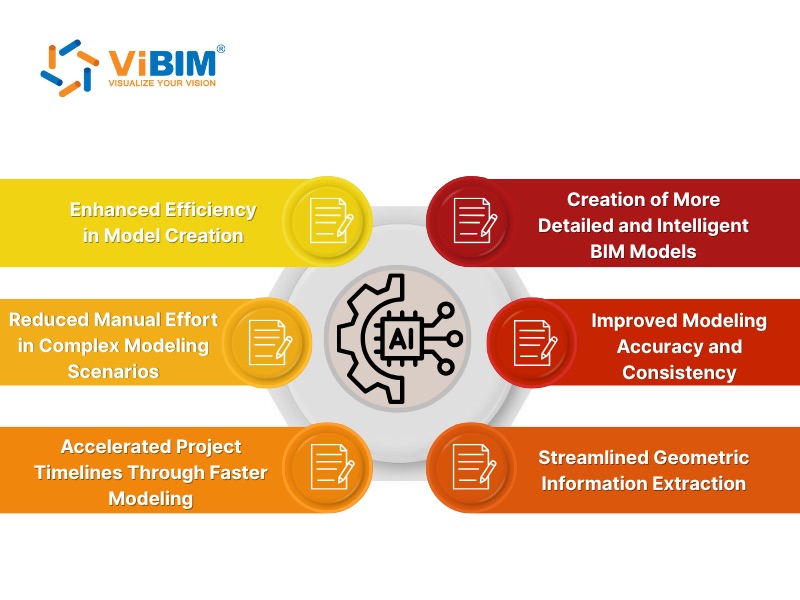

The adoption of Scan to BIM automation offers a multitude of benefits for AEC professionals, streamlining workflows and improving project outcomes. While the initial scanning and point cloud registration phases have seen significant automation through advanced tools and equipment, the modeling phase has remained a significant bottleneck. This is primarily due to the sheer number and complexity of components in existing buildings, which are often non-standard, diverse, and not in their original condition. However, the application of automation, especially powered by machine learning (ML), is now bringing transformative benefits to this critical modeling stage:

- Streamlined Geometric Information Extraction: This is the foundational technical process that enables overall efficiency. ML algorithms automate the crucial first step of segmenting and extracting specific geometric information such as the surfaces of walls, floors, and pipes directly from the raw point cloud data. This automation replaces the error-prone and slow manual process of identifying and tracing these elements, ensuring that the geometric data used to build the final BIM objects is captured precisely and consistently.

- Improved Modeling Accuracy and Consistency: Machine learning algorithms minimize errors in the modeling process through advanced pattern recognition. They can identify and accurately model elements even in complex point clouds. Furthermore, their continuous learning ability means that accuracy improves over time as the algorithms are exposed to more data and previous models, leading to more reliable and consistent BIM outputs.

- Accelerated Project Timelines Through Faster Modeling: By automating the tedious and time-consuming tasks of segmentation, feature extraction, and object placement within the modeling environment, the overall project pace is accelerated. This frees up skilled human resources from repetitive modeling tasks, allowing them to focus on higher-value activities such as quality control, analysis, and problem-solving.

- Creation of More Detailed and Intelligent BIM Models: Train machine learning models on extensive libraries of completed, high-quality Revit models. This allows the AI to learn the correct structure of components and the composition of entire buildings including architecture, structure, and complex MEP systems from perfect, structured data. Afterward, deep learning techniques can be used to perform a “paired analysis,” comparing the ideal patterns learned from the BIM models against the new, unstructured point clouds. This approach provides a more robust basis for automatic object recognition and model generation, creating a powerful feedback loop that will significantly accelerate the AI’s training and improve its capabilities over time.

The primary goal of automation is to drastically reduce the immense time investment required for manual modeling. In the future, advanced AI algorithms will be able to process massive datasets such as the complex piping and infrastructure of a 10-square-kilometer oil refinery and cut the modeling time by a third, or even by half. Achieving this level of acceleration remains the key driver for innovation in this field.

Future Trends in Scan to BIM Automation

The evolution of Scan to BIM automation is not about a single solution but rather a series of developing technological trends, each tackling a different aspect of the complex modeling process. These trends represent the industry’s shift from basic automation to more intelligent, context-aware systems. The most significant of these are focused on improving how raw scan data is interpreted, cleaned, and converted into intelligent BIM objects.

Automated Feature Recognition and Segmentation

The foundational trend in Scan to BIM automation is the move away from manual tracing toward automated feature recognition. Current and emerging software solutions are increasingly incorporating algorithms designed to automatically identify and segment basic geometric primitives—such as planes (for walls and floors), cylinders (for pipes and columns), and spheres—directly from the raw point cloud. The goal of this trend is to eliminate the most laborious step in the process, allowing systems to provide a preliminary massing of the existing conditions that human modelers can then refine, rather than having to build everything from scratch.

Intelligent Point Cloud Cleaning and Optimization

A more advanced and forward-looking trend involves using AI to actively “heal” or optimize the raw point cloud data before modeling begins. Scans are rarely perfect and often contain noise from reflective surfaces or data gaps from physical obstructions. The trend is to develop intelligent systems that can learn to identify and automatically remove this noise and, in some cases, even intelligently fill in small gaps based on the surrounding geometry. This ensures that the data used for the automated modeling process is as clean and complete as possible, leading to more accurate and reliable outputs with less need for manual correction.

Context-Aware Modeling with Machine Learning

Perhaps the most significant future trend is the development of context-aware modeling systems powered by machine learning. This goes beyond simple geometric recognition. The vision is for AI to leverage vast libraries of previously completed projects and manufacturer component data to not only identify a shape but to understand what it is. For example, instead of just seeing a cylinder, a future system could identify it as a “DN200 carbon steel chilled water pipe” and automatically apply the correct classification and associated data. This trend promises to be the true game-changer, drastically accelerating the creation of genuinely intelligent, data-rich BIM models and moving the process far beyond simple geometric representation.

Challenges and Limitations of Scan to BIM Automation

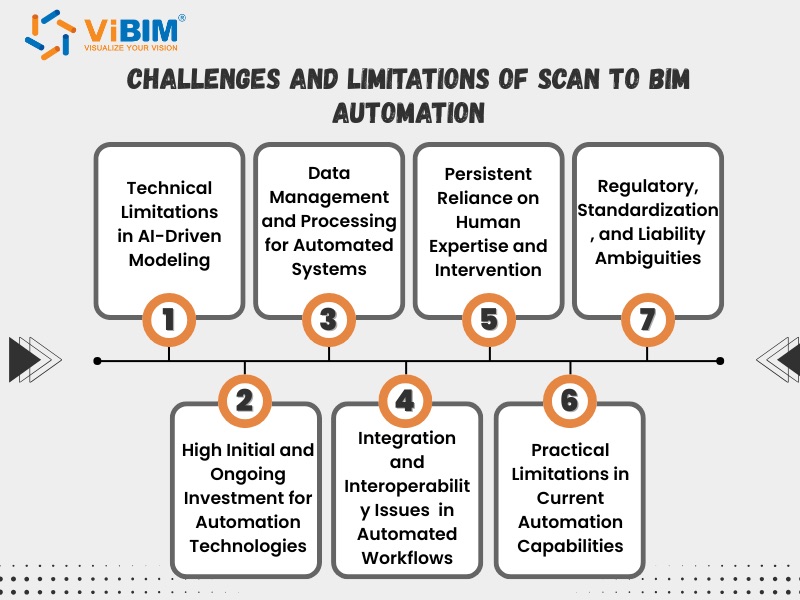

Despite its transformative potential, the path to fully automated Scan to BIM workflows is paved with specific challenges and limitations, particularly concerning the capabilities and implementation of the automation technologies themselves:

- Technical Limitations in AI-Driven Modeling: Current AI and machine learning algorithms, while rapidly advancing, still struggle with highly complex or irregular geometries, such as intricate MEP (Mechanical, Electrical, and Plumbing) systems or unique architectural features found in older buildings. Object recognition is not yet foolproof; automated systems may misclassify or fail to identify certain building elements within the point cloud, often necessitating manual review and correction to ensure the accuracy of the final BIM model.

- High Initial and Ongoing Investment for Automation Technologies: The adoption of advanced Scan to BIM automation requires a significant financial commitment. This includes the cost of specialized software licenses for automated modeling, AI-driven point cloud processing, and sophisticated BIM platforms. Furthermore, ongoing expenses related to training personnel to use these advanced tools, regular software updates, and the maintenance of high-performance computing hardware add to the long-term financial considerations, which can be a barrier, especially for smaller firms.

- Data Management and Processing Bottlenecks for Automated Systems: High-resolution 3D scanning generates vast volumes of point cloud data. While data storage is a general concern, the automated processing of these terabytes of data by AI algorithms demands substantial computational power and can strain IT infrastructure. Moreover, imperfections in raw scan data, such as noise from cluttered environments or occlusions leading to incomplete scans, can significantly complicate automated data cleaning and feature recognition, potentially reducing the effectiveness of automated modeling routines.

- Integration and Interoperability Issues in Automated Workflows: Seamless data flow is critical for efficient automation. However, incompatibilities can arise between different software tools used in the Scan to BIM process—from the scanning hardware’s output format to the automated processing software and the final BIM authoring platform. These interoperability gaps can force time-consuming data conversions, risk information loss, and disrupt what should ideally be a fluid, automated workflow. The lack of universally standardized protocols for automated Scan to BIM processes can also lead to fragmented approaches and inconsistent model outputs across different projects or teams.

- Persistent Reliance on Human Expertise and Intervention: Even with advanced automation, human oversight remains crucial. There can be skepticism or resistance to fully relying on automation for critical modeling tasks, leading many firms to adopt hybrid approaches where AI assists human modelers. Furthermore, a skills gap often exists; there’s a limited availability of technicians proficient in both the nuances of laser scanning data and the sophisticated operation of automated BIM modeling software, which can hinder effective implementation.

- Practical Limitations in Current Automation Capabilities: Today’s automation tools are highly effective for certain repetitive tasks, such as the extraction of standard walls, slabs, or columns. However, they often struggle with non-standard, unique, or highly detailed architectural elements (e.g., ornate historical building details, custom fixtures). This means that a significant portion of the modeling workflow, often estimated between 30-50%, may still require manual effort, indicating that fully “hands-off” automation is not yet a widespread reality.

- Regulatory, Standardization, and Liability Ambiguities: The application of automation introduces questions regarding standards and accountability. There can be ambiguity in defining and consistently achieving appropriate Levels of Detail (LOD) for models generated through automated processes, potentially leading to over-or-under-specification. Additionally, uncertainties surrounding the accuracy standards for AI-generated models and who bears responsibility for any discrepancies can pose risks in contractual agreements and regulatory compliance.

ViBIM’s Approach to Scan to BIM Automation

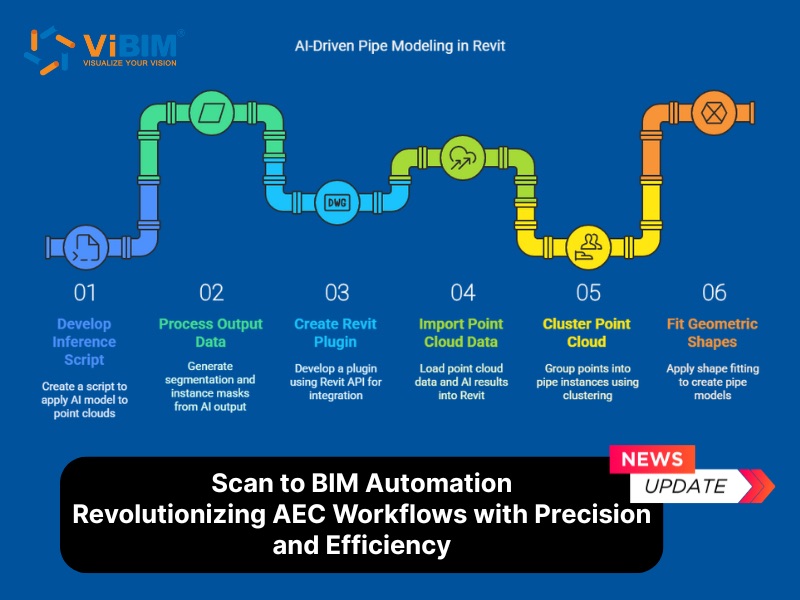

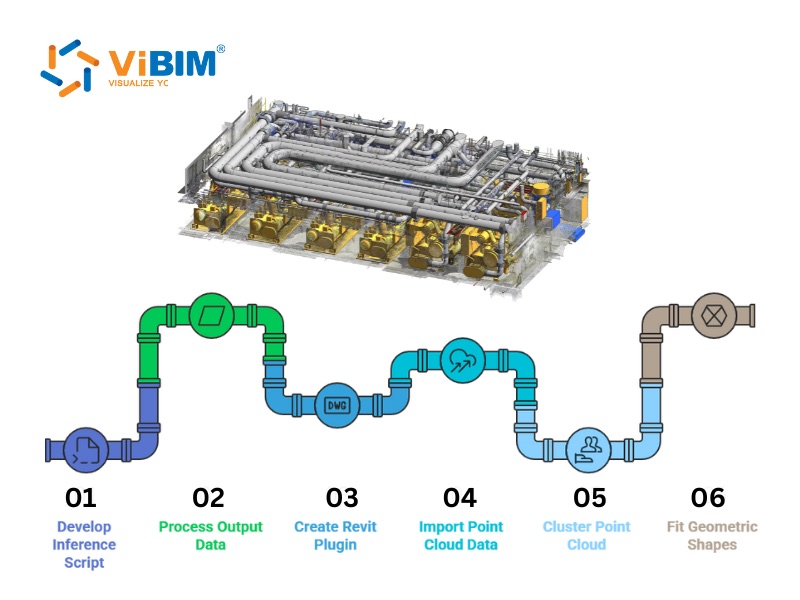

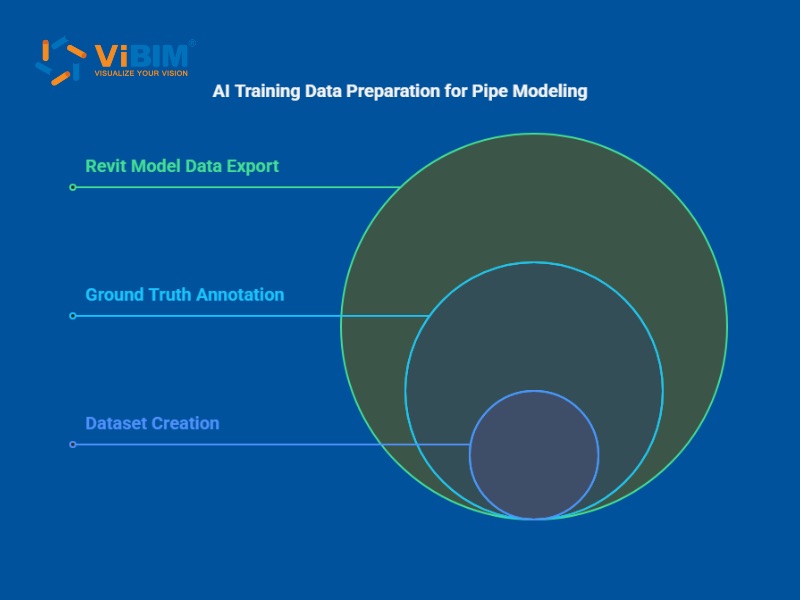

At ViBIM, which specializes in providing scan to bim modeling services, we are actively investing in and developing advanced automation modeling capabilities through AI. Our integrated workflow for Scan to BIM automation (specifically for Pipe Modeling) encompasses several key technological and solution-driven principles:

- Intelligent Point Cloud Data Processing: We begin by efficiently processing raw point cloud data. This involves exporting the point cloud into a suitable format to serve as a basis for integration with our existing machine learning algorithms for in-depth analysis, followed by crucial normalization, voxelization, and augmentation to standardize and preprocess the data for optimal AI analysis.

- Precision Data Labeling for AI Training: To train our AI models effectively, we employ meticulous data labeling. This involves both semantic segmentation, classifying each point in the point cloud as either “pipe” or “non-pipe,” and instance segmentation, assigning a unique ID to every individual pipe segment.

- Advanced AI Model Training with Deep Learning: Our core automation is powered by robust deep learning models. We utilize Sparse Convolutional Neural Networks (Sparse CNNs), ideal for handling sparse point cloud data, and Point Transformer Networks, which enhance accuracy through attention mechanisms. The training process is optimized using various loss functions (e.g., Cross-Entropy, Lovasz), optimizers like AdamW, and sophisticated learning rate schedules.

- Seamless AI Integration into Revit: A custom-developed Revit plugin (built with C#) serves as the bridge between our AI models and the Revit environment. This plugin is designed to:

- Receive segmented data directly from the AI.

- Apply advanced clustering algorithms to group points into distinct pipe segments.

- Utilize Geometric Fitting libraries (such as Open3D or PCL) to accurately identify the geometric properties of pipes (e.g., circular pipes, elbows, tees).

- Automatically generate true Pipe objects within Revit using the Revit API, complete with accurate dimensions and properties.

- Automated Output and User Interaction: The final stage focuses on user experience and validation. Our system displays segmentation results, allowing for a clear comparison between ground truth and AI predictions. Furthermore, a user-friendly interface within Revit provides quick and intuitive interaction with our AI-powered tools.

See more: Scan to BIM Pricing and Cost Factors

Scan to BIM automation is undeniably revolutionizing workflows within the AEC industry. By seamlessly integrating the physical and digital worlds, it offers unprecedented levels of accuracy, efficiency, and collaboration. The benefits, ranging from significant time and cost savings to improved project quality and enhanced as-built documentation, are compelling. While challenges related to data quality, software limitations, and the need for skilled expertise persist, the ongoing advancements in AI, machine learning, and cloud computing are continuously pushing the boundaries of what is possible. As these technologies mature and become more accessible, Scan to BIM automation will undoubtedly become an even more integral part of the AEC landscape, empowering professionals to deliver better, faster, and more sustainable built environments.