The fundamental difference is that shop drawings are created before construction to detail the fabrication and installation of specific components, while as-built drawings are created after construction to document what was actually built, including all modifications.

While both are essential for a project’s success, they serve distinct purposes at different stages. In this guide, we will break down the seven critical differences, clarifying who creates them, when they are used, and why they are indispensable in the construction industry.

What Are Shop Drawings?

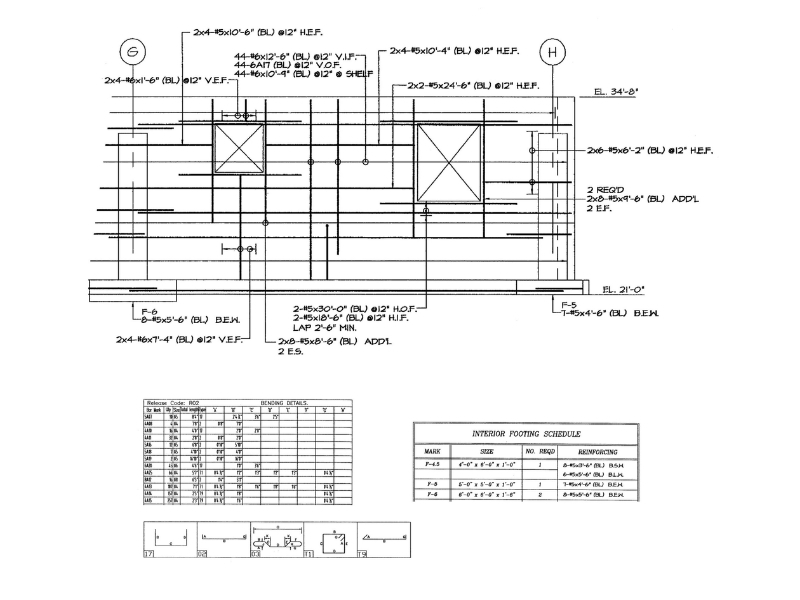

Shop drawings are detailed illustrations created by contractors, subcontractors, suppliers, or manufacturers for the manufacturing, assembling, and installing specific construction components.

Shop drawings are used to clarify and expand upon the information in the design drawings, providing specific details for fabrication and installation. They provide precise dimensions, material specifications, and assembly instructions for specific components like structural steel, windows, elevators, and MEP (mechanical, electrical, plumbing) systems to ensure every piece is built and installed correctly, often requiring a level of detail comparable to lod 300 in BIM.

They are essential because design drawings, even technical ones, do not include granular installation details. For instance, while an architect’s design may specify a 2.7m high gypsum ceiling with aluminum hangers, it is the contractor’s shop drawing that clarifies the critical specifics: the exact type and thickness of the aluminum frame, the hook mechanism, the type of suspension wire, and the precise layout for on-site assembly.

Key Characteristics of Shop Drawings:

- Created Pre-Construction: They are prepared by contractors, fabricators, or suppliers before construction starts.

- Highly Specific and Detailed: They provide precise, actionable details that go beyond the architect’s plans, including exact dimensions, material specifications, fabrication methods, assembly instructions, and connection details.

- Requires Formal Approval: Shop drawings must be reviewed and formally approved by the architect and engineer to ensure they comply with the design intent, safety standards, and the BIM execution plan before fabrication can start.

- Guides Fabrication and Installation: They serve as a clear instruction manual for the workshop and field teams, guiding exactly how to manufacture, assemble, and install specific components like structural steel, custom cabinetry, or HVAC systems.

- Trade-Specific: These drawings are highly specialized for individual trades. For example, a plumbing contractor will create shop drawings for their system that are distinct from those created by a structural steel fabricator.

Source image from en.wikipedia.org/wiki/Shop_drawing

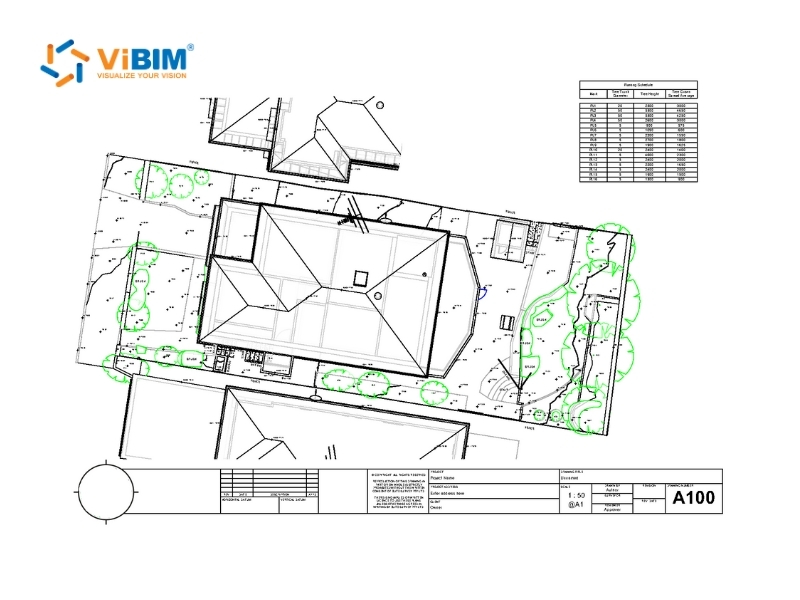

What Are As-Built Drawings?

As-built drawings, sometimes called record or redline drawings, are the official record of a project as it was actually constructed. They begin as the original design drawings but are meticulously updated throughout the construction process to reflect any changes, deviations, or modifications made on-site. The purpose of as-builts is to create a final, accurate representation of the completed building, capturing every alteration from the initial plan.

No matter how perfect a design is, unforeseen issues and on-the-fly adjustments are common. As-built drawings document these critical changes, including:

- Location Changes: Deviations in the final placement of walls, windows, or doors.

- Material Changes: Any substitutions for specified materials.

- Dimensional Changes: Alterations to the size or dimensions of rooms or components.

- Installation Changes: Modifications to the routing of systems like HVAC, electrical, or plumbing.

This final set of documents is crucial for future maintenance, renovations, and facility management, providing a reliable reference for the building’s entire lifecycle.

Key Characteristics of As-Built Drawings:

- Created Post-Construction: They are finalized after construction is complete to form a definitive record of the finished project.

- Documents All Changes: They meticulously record every deviation from the original plans, including alterations, additions, omissions, and changes to materials or locations.

- Provides Accurate Representation: They capture the actual measurements, locations, and “as-is” conditions of the completed structure, ensuring future work is based on reliable data.

- Essential for Facility Management: They are an invaluable resource for building owners and facility managers, providing a detailed map of all systems and components, often integrated with data standards like Cobie in BIM, for ongoing maintenance and future renovations.

- Serves as Legal and Verification Tool: As-built drawings act as legal documentation of the completed work and are used to verify that the project was constructed according to the contract, helping resolve any potential disputes.

Difference Between Shop Drawings and As-Built Drawings

While both documents are vital to a project’s lifecycle, they serve fundamentally different functions. This table provides a clear, side-by-side comparison of their most important distinctions.

| Feature | Shop Drawings | As-Built Drawings |

| Purpose | To guide the fabrication and installation of specific components. | To document the final state of the entire project as it was actually constructed. |

| Stage of Creation | Before construction begins. | During and after the construction process. |

| Specificity | Highly detailed for a single component or system (e.g., HVAC, steel beams). | A comprehensive record of the entire building, showing final locations and dimensions. |

| Intended Audience | Fabricators, installers, and the project team for review and approval. | Building owners, facility managers, and future renovation teams. |

| Creator | Contractor, subcontractor, supplier, or fabricator. | The general contractor, updated based on field markups. |

| Changes and Deviations | Propose how to meet the design intent; they do not document deviations. | Document deviations from the original design that occurred during construction. |

| Legal Documentation | Part of the submittal process to ensure contract compliance before work begins. | A final deliverable that serves as a permanent legal record of the completed work. |

How Shop Drawings and As-Builts Work Together in a Project

Shop drawings and as-built drawings are not independent documents; they are sequential parts of a continuous workflow that ensures a project is built correctly and recorded accurately.

- Design Intent: The architect and engineer create the initial design documents—encompassing the phases that define what is SD DD CD means—which outline the project’s vision and requirements.

- Shop Drawing Creation: An HVAC subcontractor uses these designs to create detailed shop drawings for the ductwork system, specifying exact dimensions, materials, and connection points for fabrication.

- Approval & Fabrication: The architect and engineer review and approve the shop drawings, confirming they align with the design intent. The subcontractor then fabricates the ductwork based on these approved plans.

- On-Site Modification: During installation, the team discovers an unforeseen structural beam, a conflict that might have been missed even with tools like Navisworks Clash Detection. To avoid a physical clash, they must reroute a section of the ductwork, which now deviates from the approved shop drawing.

- As-Built Documentation: The contractor marks this change directly onto the master drawings. This field markup, along with all other on-site changes, is later used to create the final as-built drawings.

Why Choose ViBIM for Your As-Built Drawings?

Creating accurate as-built documentation requires more than just drafting skills; it demands precision technology. ViBIM upgrades this process through our specialized As-Built Drawing Services. By combining precise Revit BIM Modeling Services with a rigorous quality control process, we deliver the “final map” your project deserves.

- Unmatched Precision with Scan-to-BIM: We don’t guess; we capture reality. By modeling directly from high-resolution point cloud data, we ensure your 2D drawings reflect the exact real-world conditions, completely eliminating the discrepancies common in traditional manual surveys.

- Proven Reliability & Speed: We understand that time is money in construction. ViBIM maintains a 99% on-time delivery record and utilizes optimized workflows that are up to 30% faster than the market average, keeping your renovations and handovers on schedule.

- Comprehensive Standard Compliance: Whether you require adherence to international standards (like ISO 13567, US NCS) or your firm’s specific layering and annotation protocols, our outputs are customized to integrate seamlessly into your existing system.

- Full Format Flexibility: We deliver more than just PDFs. You receive a fully coordinated documentation set in Revit (.rvt), CAD (.dwg), and PDF formats, ensuring you have the right data for Facility Management or future expansion.

In essence, shop drawings serve as the detailed roadmap for construction, while as-built drawings are the final map of what was actually built. By comparing the as-builts to the original shop drawings, project teams can verify quality, troubleshoot issues, and provide the owner with a reliable record for the building’s entire lifecycle.

FAQs

Can as-built drawings and shop drawings be used interchangeably?

No, they cannot be used interchangeably. Shop drawings are proactive documents used for pre-construction fabrication, while as-built drawings are reactive documents that record the final post-construction reality. Using one in place of the other would lead to significant errors in either fabrication or facility management.

Are as-built drawings the same as record drawings?

While the terms are often used interchangeably, there is a technical difference. As-built drawings are the marked-up documents prepared by the contractor detailing on-site changes. Record drawings are typically prepared by the architect or engineer, who take the contractor’s as-built information and incorporate it into a final, clean set of official drawings for the owner.

This solution offers a highly accurate alternative to traditional 2D markups for creating as-built drawing and record documentation. As-Built Scan to Modeling Services involve using 3D laser scanners to capture the exact, real-world conditions of the completed construction site. This data is then utilized by Scan to BIM Revit Services to create a precise Building Information Model (BIM) that serves as a rich, intelligent digital as-built model. This model is not just a drawing but a database, providing an accurate record of the final building that is invaluable for future facility management, operations, and renovations.

In conclusion, both shop drawings and as-built drawings are indispensable. While shop drawings provide the detailed roadmap for fabrication before work begins, as-built drawings offer the final, truthful record of what was actually constructed. Understanding the distinct roles of each is fundamental to ensuring project accuracy, quality control, and efficient lifecycle management.