Digital twin technology and Building Information Modeling (BIM) both play a significant role in enhancing the design, construction, and management of construction projects. A digital twin is a virtual and real-time copy of a physical asset that mirrors its performance through live sensor data, while BIM is a process that creates intelligent 3D models to support design, construction, and facility management. Each technology contributes unique benefits at different stages of a project.

The key distinction lies in their purpose: BIM focuses on creating accurate models for design and construction, whereas digital twins are used during operation and maintenance to monitor and optimize real-world performance. This article explains what digital twins and BIM are, highlights the differences between them, and shows how integrating both can improve project outcomes. Continue reading to gain a detailed understanding of the comparison between digital twin vs BIM.

What is a digital twin?

A digital twin is a dynamic virtual copy of a real object, system, or process that receives continuous data from sensors to reflect actual performance and conditions. These digital models allow engineers and operators to observe, simulate, and analyze how the asset behaves in different situations, which helps predict maintenance needs and improve efficiency.

What is BIM?

Building Information Modeling (BIM) is a process of creating, optimizing, and managing digital information throughout the entire lifecycle of a built asset from design and construction to operation. At its core, BIM utilizes intelligent 3D BIM models as a foundation to integrate data from multiple disciplines, enabling enhanced visualization, coordination, and informed decision-making. Through BIM, project teams can identify design issues early, enhance collaboration, and ensure consistent quality and performance across every project phase.

What are the differences between digital twins and BIM?

BIM and Digital Twin both create digital versions of physical assets, but their purposes and applications are different. BIM focuses on the design and construction phases, helping project teams visualize and coordinate building data before the asset is built. A Digital Twin mirrors the real asset during operation, using live data to track performance and support maintenance decisions. Their differences can be clearly seen across purpose, data type, lifecycle coverage, simulation, monitoring, and scope.

| Aspect | BIM | Digital twin |

| Purpose and focus | Used for design, planning, and construction; focuses on visualizing and coordinating building data. | Used for operations and maintenance; focuses on monitoring, analysis, and performance optimization. |

| Data Type and dynamics | Relies on static, design-stage data, including geometry, materials, and documentation. | Uses dynamic, real-time data from sensors, IoT devices, and operational systems. |

| Lifecycle coverage | Supports mainly the design and construction phases. | Covers the full asset lifecycle from design to decommissioning. |

| Simulation and analytics | Enables limited simulations like energy modeling or clash detection. | Performs predictive analytics, advanced simulations, and scenario testing. |

| Real-time monitoring and interaction | Represents a static snapshot of the asset at one point in time. | Continuously mirrors real-world conditions for active monitoring and decision-making. |

| Scale and scope | Usually applies to a single building or project. | Can model interconnected assets such as campuses, networks, or cities. |

BIM and Digital Twin are not competing systems but complementary ones. BIM provides the data foundation and structured design models that form the base for a Digital Twin. When integrated, they create a connected workflow where the information developed during design continues to add value during operations, helping teams manage assets more effectively across their lifespan.

To better understand how these technologies differ in practice, the following sections detail their unique characteristics across several key aspects.

Purpose and focus

BIM was developed to facilitate effective collaboration among architects, engineers, and contractors during the design and construction process. It functions as a shared digital workspace for managing drawings, schedules, and specifications in one coordinated environment.

Digital twins shift attention to the operational phase, offering a live model that enables facility managers to monitor system performance, track energy efficiency, and enhance comfort. In short, BIM supports how an asset is built, while a Digital Twin supports how it is run.

Data type and dynamics

The data within BIM is mostly static, created during the design phase and updated only at key milestones, such as construction completion. It includes information about geometry, materials, and system components, serving as a reference for how the project was designed.

A digital twin utilizes continuous, real-time data from sensors and connected systems. This enables it to accurately represent how the asset behaves under real-world conditions, displaying changes in energy use, temperature, or occupancy patterns as they occur.

Lifecycle coverage

BIM plays its strongest role during the design and construction stages. After handover, its relevance often declines unless updates are manually added by the facility team. For existing structures, utilizing Scan to BIM for FM ensures that the facilities management team has a geometric and data-rich starting point for operational software.

Digital twins, by contrast, remain active throughout the asset’s life. They connect design data with operational information, supporting maintenance, renovation, and even decommissioning, which keeps the model accurate and useful over time.

Simulation and analytics

BIM supports practical simulations like structural analysis, lighting studies, or clash detection, which help reduce design errors before construction. These simulations are valuable but remain tied to static design assumptions.

A digital twin expands those capabilities through predictive analytics and scenario testing. It can simulate how systems respond to weather changes or predict when equipment might need service, allowing users to make proactive adjustments.

Real-time monitoring and interaction

A BIM model serves as a static reference of how the building was originally designed. It shows components and layouts but does not track actual performance or conditions.

A digital twin, in contrast, connects directly to live data streams, providing continuous insight into the asset’s health and performance. This connection enables operators to visualize, analyze, and interact with real-time information, facilitating smarter facility management.

Scale and scope

BIM typically applies to a single project, capturing detailed information about one building’s structure, systems, and layout. Its focus remains on specific project deliverables.

A digital twin can operate at a much larger scale, covering multiple buildings, infrastructure systems, or entire cities. It models how assets and processes interact, providing a unified view that supports coordination across connected environments.

How to use digital twin and BIM across the project lifecycle?

To use digital twin and BIM effectively across the project lifecycle, teams need to combine BIM for building and design phases with digital twins for management and operation. Each tool has its own strength that supports specific phases of a project while keeping data consistent and accessible throughout its lifecycle.

Building and designing with BIM:

- Planning: In the planning stage of a project, conceptual design tools give teams a shared virtual space to brainstorm, visualize early concepts, and exchange feedback with other stakeholders. This early coordination helps align design intent and project goals before detailed modeling begins.

- Design: When adjustments are needed in a project’s layout or structure, BIM 3D models make it easy to modify designs, detect conflicts, and correct technical issues before construction starts. The visual accuracy of BIM helps designers test ideas quickly while maintaining precise control over every detail.

- Execution: As construction begins, BIM 3D models serve as a guide, providing teams with a clear view of constructibility and sequence. The model facilitates on-site coordination and enables workers to compare their physical progress with the planned design, ensuring the entire process remains organized and efficient.

Managing and operating with digital twins:

- Model: Digital twins of construction activities act as ongoing records of progress. As milestones are completed, the models are continuously updated through scans or documentation so that teams always maintain accurate insight into project performance and history.

- Simulate: Digital twins offer photorealistic visualizations that replicate physical spaces using data captured by cameras or mobile devices. Sharing these immersive simulations helps stakeholders experience how people might move through a space, which supports better planning and informed decision-making.

- Manage: With detailed and current visual data, digital twins simplify daily facility management tasks. Combined with BIM 3D models, they allow operators to conduct virtual inspections, reducing the need for frequent on-site visits and saving time in maintenance coordination.

How to integrate BIM and digital twins?

Smart buildings require systems that deliver real-time and dynamic insights. Digital twins serve as the bridge that connects real-world data with your BIM model, enabling project teams to work faster and make more informed decisions. Here are five steps showing how digital twins can be integrated with common 3D design software:

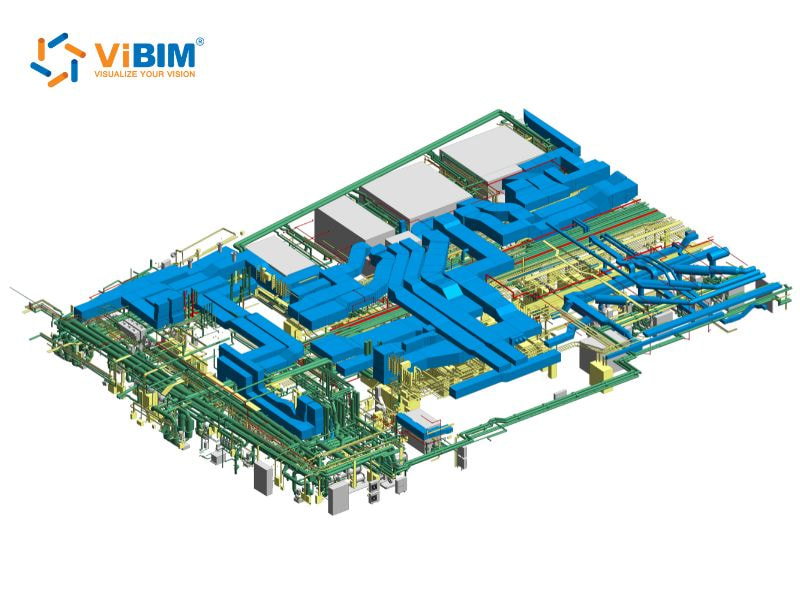

- Step 1- Design and Construction Phase: Using software like Revit or ArchiCAD, a detailed BIM model is developed to represent architectural, structural, and MEP systems. Each object is embedded with metadata describing its geometry, material, and functional parameters — laying the digital foundation for future twin integration.

- Step 2 – Construction Updates and As-Built Model: As construction progresses, on-site changes are synchronized back into the BIM model. Design adjustments, material substitutions, and equipment relocations are continuously captured, ensuring the model mirrors actual site conditions. This dynamic updating process makes the BIM a reliable base for creating a digital twin later on.

- Step 3 – Handover to Owner: Upon project completion, the as-built BIM model is handed over to the owner along with asset information such as maintenance schedules, warranties, and performance data. This enriched dataset bridges the gap between construction and facility management, allowing the model to connect seamlessly with digital monitoring systems.

- Step 4 – Integration with Operational Systems: The as-built BIM is then integrated with operational technologies like IoT sensors, Building Management Systems (BMS), and other data platforms. BIM provides the spatial and asset framework, while these connected systems feed real-time data (e.g., temperature, occupancy, or equipment status) into it.

- Step 5 – Digital Twin Creation: By combining the static BIM model with live sensor inputs and analytics, a digital twin emerges. This twin continuously reflects the building’s actual performance. Facility managers can now simulate scenarios, predict maintenance needs, and make data-driven decisions to improve efficiency and sustainability.

What are the benefits of integrating BIM and digital twin?

Integrating BIM and digital twin technologies unifies design, construction, and operation processes, creating a connected data environment that supports smarter and more efficient project management. This integration delivers three key benefits:

- Real-time performance monitoring and predictive maintenance: By integrating sensor data with BIM models, digital twins provide live insights into HVAC performance, energy consumption, occupancy, and equipment health. This enables predictive maintenance, reduces downtime, lowers the risk of equipment failure, and supports smoother, more reliable building operations.

- Optimized energy use and sustainability: To achieve true sustainability, BIM provides the necessary physical context (geometry, material thermal properties, and insulation data), while the Digital Twin supplies real-time environmental and usage data. Combining these allows teams to run high-fidelity performance simulations that accurately reflect reality, not just theory. This synergy helps identify specific areas for energy optimization, reduces operational costs, and supports rigorous sustainability goals such as LEED certification.

- Enhanced project lifecycle management: BIM data often gets siloed once construction ends, but a Digital Twin ensures that this valuable data lives on. By acting as a bridge, the Digital Twin enables an effortless transition of data from the design and build phases into facility management. This continuity ensures that owners have immediate access to accurate asset history and site conditions, allowing for efficient resource allocation, smarter long-term planning, and the maximization of the asset’s longevity without the typical data loss between project stages.

The article has provided a clear comparison between digital twin vs BIM, explaining how each supports different phases of a building’s lifecycle. It discussed their definitions, key differences, and how integrating both can strengthen design, construction, and operation processes. Readers can now understand how these technologies complement each other and how data integration drives better project outcomes.

ViBIM specializes in specialized point cloud to BIM services using Revit on the Autodesk platform, supporting building survey work, existing conditions, and as-built documentation for design and engineering needs. A key strength is ViBIM’s ability to deliver accurate as-built models from Scan to BIM, which serve as essential input for later Digital Twin development. Contact ViBIM to discuss your project and request a complimentary quote for high-quality Revit modeling services.

ViBIM – Revit Modeling Outsourcing

- Address: 10th floor, CIT Building, No 6, Alley 15, Duy Tan street, Cau Giay ward, Hanoi, Vietnam

- Phone: +84 944 798 298

- Email: info@vibim.com.vn