A quantity takeoff refers to the process of identifying, measuring, and listing all materials and sometimes related labor from project drawings, blueprints, or 3D models. Manual methods depend on physical documents and hand calculations, while digital quantity takeoff applies software to extract measurements and quantities directly from digital files or models. Both aim to provide a detailed breakdown that supports clear, consistent cost data across project phases.

Quantity takeoff involves estimators, engineers, and project managers who translate technical drawings into measurable values that shape realistic budgets and contracts. The process begins with input data collection and validation, then moves to output analysis that produces the quantities, costs, and project insights. This approach defines what is measurable—such as counts, areas, or volumes—while excluding indirect items such as scaffolding or transportation. By understanding what is and isn’t included, teams can maintain transparency and accuracy.

This article explains what is quantity take off, the difference between quantity and material takeoff, the three methods applied, the professionals involved, and what is included or not included in a quantity takeoff. Readers can gain a clearer view of how this process supports precise cost management and informed decision-making in construction projects.

What is a quantity takeoff?

A quantity takeoff (QTO), is the process of reviewing project drawings, blueprints, or 3D models to measure and record all materials needed for a construction project. The QTO is generated during preconstruction planning at the earliest stages of a project. The process involves breaking down the project into smaller, measurable sections and compiling a detailed document that helps stakeholders forecast costs and make accurate budget decisions.

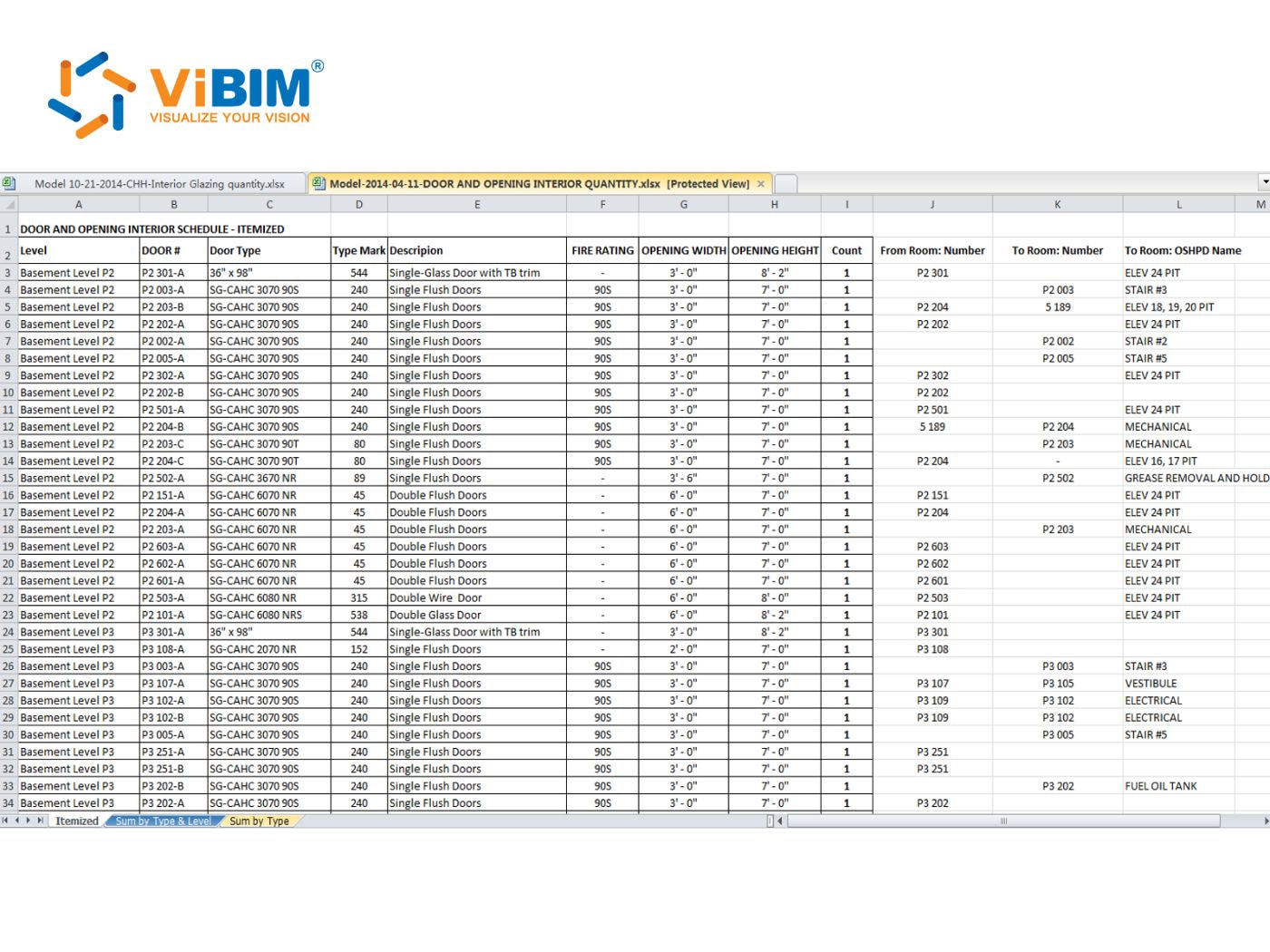

The primary goal of a QTO is to create a complete list of every item required for construction, from major materials such as cubic meters of concrete and tons of steel to smaller components like doors, light fixtures, and electrical outlets. This list of quantities provides the foundation for cost estimation, as each item can then be assigned a price to calculate the total project cost. Accurate quantities ensure budgets are realistic, procurement is efficient, and resources are allocated properly, helping the project stay within scope and schedule.

Common names used to describe quantity takeoff include:

- Construction takeoffs

- Material estimating

- Material takeoffs

- Material counts

- Quantity surveying

- Estimating takeoffs

- Earthwork takeoffs

Quantity takeoff vs. Material takeoff

While Quantity Takeoff (QTO) and Material Takeoff (MTO) are often mentioned together in construction planning, the two terms represent different scopes of work. Material Takeoff (MTO) refers to the process of compiling a complete list of all physical materials required for a construction project. It identifies the type, grade, size, and quantity of every item that must be purchased, helping procurement teams and contractors plan purchases, manage inventory, and minimize supply delays or waste.

The main difference lies in their purpose and level of detail. QTO includes both materials and measurable work activities to support cost estimation and resource allocation, whereas MTO focuses solely on the physical materials required for construction. In other words, QTO provides a broader view of project quantities, whereas MTO delivers the exact data needed for procurement and delivery planning.

The table below highlights the key differences between QTO and MTO for a clearer understanding.

| Aspect | Quantity Takeoff (QTO) | Material Takeoff (MTO) |

| Scope & Focus | Broad overview of project quantities, covering materials and measurable work. | Focuses on specific material types, grades, and specifications. |

| Usage | Used for cost estimation, budgeting, and bidding. | Used for procurement planning and inventory control. |

| Impact on Project Management | Defines project scale and resource needs. | Maintains accurate ordering and material flow. |

| Detail Level | General quantities and dimensions. | Detailed material counts and specifications. |

| Application | Supports budgeting and bid preparation. | Supports purchasing and supplier coordination. |

Innovations in Quantity Takeoff: Tech and Tools

The traditional method of performing quantity takeoffs involved painstaking manual measurements from paper blueprints. However, technology has significantly streamlined and improved this process.

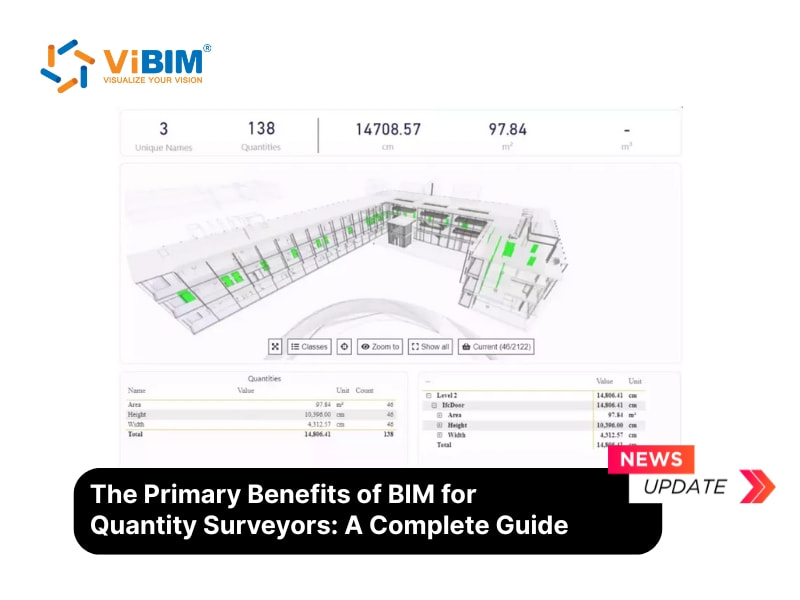

The Impact of Building Information Modeling (BIM) on Takeoffs

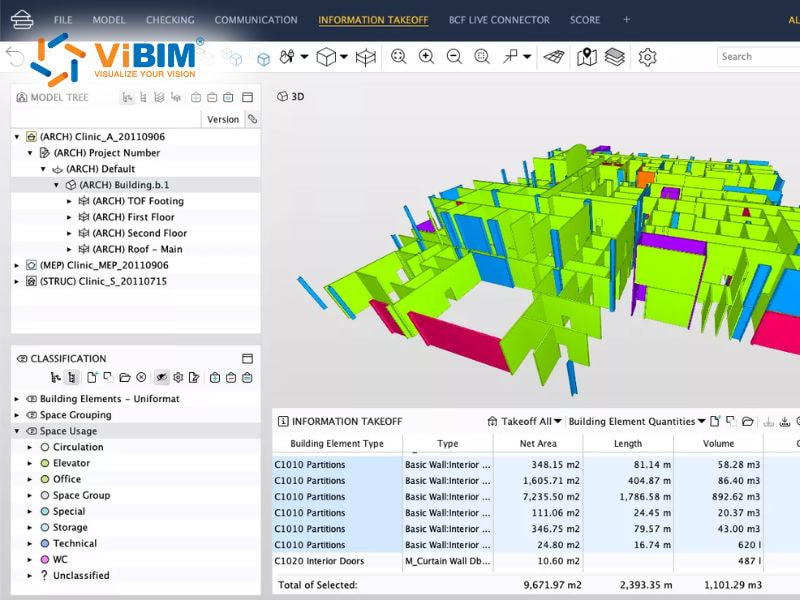

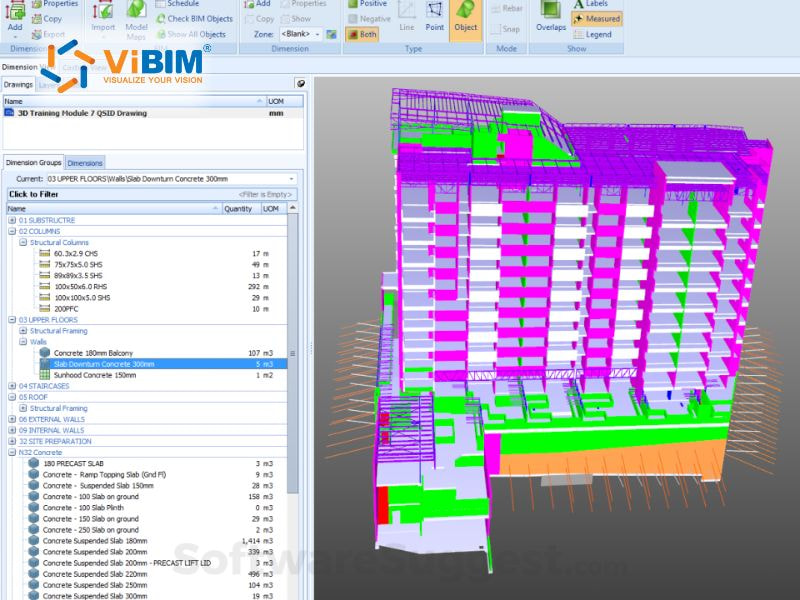

BIM’s 3D models act as a “living” database, transforming takeoffs from static reports into dynamic outputs. When the design is updated, quantity reports can be regenerated instantly, ensuring the estimate always matches the current plan. This eliminates errors caused by referencing outdated 2D drawings.

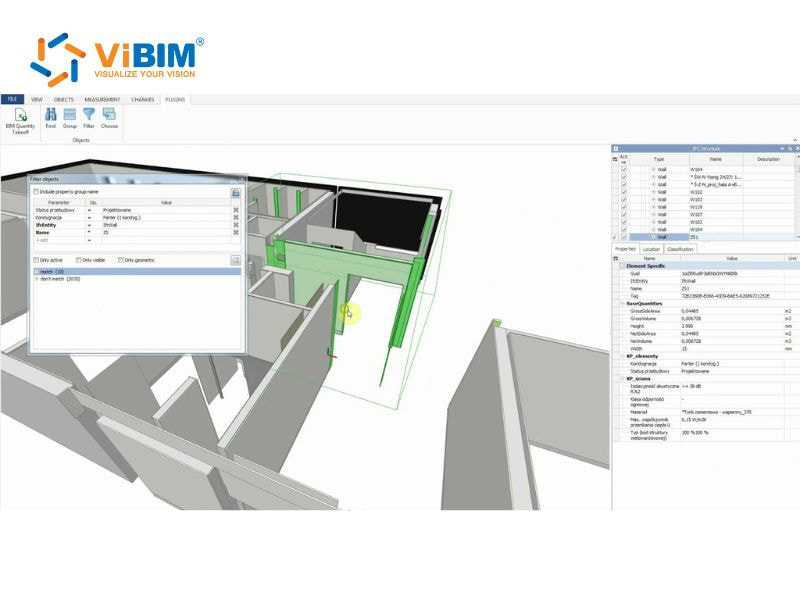

This single source of truth provides extreme accuracy and granularity, allowing for the precise quantification of complex items like fittings or joints. Furthermore, estimators can use the model for visual validation, highlighting items from a report (e.g., “all 4-inch elbows”) to instantly see their location and context within the 3D environment.

To leverage these real-time insights for better cost control and reporting throughout the project lifecycle, explore the specific benefits of BIM for quantity surveyors.

The Role of Computer-Aided Design (CAD) in Quantity Takeoffs

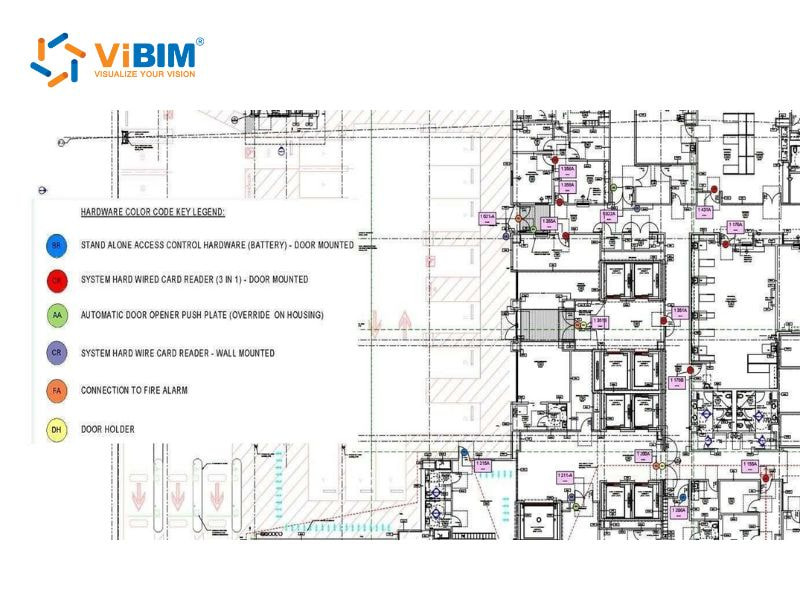

Before the widespread adoption of BIM, CAD software primarily produced 2D drawings and served as the primary tool for design. Estimators handled quantity takeoffs manually from printed sheets or digitally with software that measured files in formats like DWG or PDF, yet they still interpreted various 2D views, such as plans and sections, to grasp the full structure, which often led to errors.

Traditional estimating software offers preset quantity lists for various project types, requiring users to extract numbers from 2D drawings, enter them into fields, and then add unit prices. As a result, manual steps remain heavy and prone to error. BIM changes this by pulling quantities directly from the 3D model data and allowing users to tweak as needed, while embedded details in components trigger automatic updates during changes, boosting precision and team coordination.

For a deeper look at the workflow used to align these architectural, structural, and MEP models into a unified project, check out our guide on what is BIM coordination.

Types of quantity takeoffs

There are two primary types of quantity takeoffs used in construction projects: manual quantity takeoffs and digital quantity takeoffs. Each method offers distinct accuracy and efficiency levels, which will be explained further in the next section.

Manual quantity takeoff

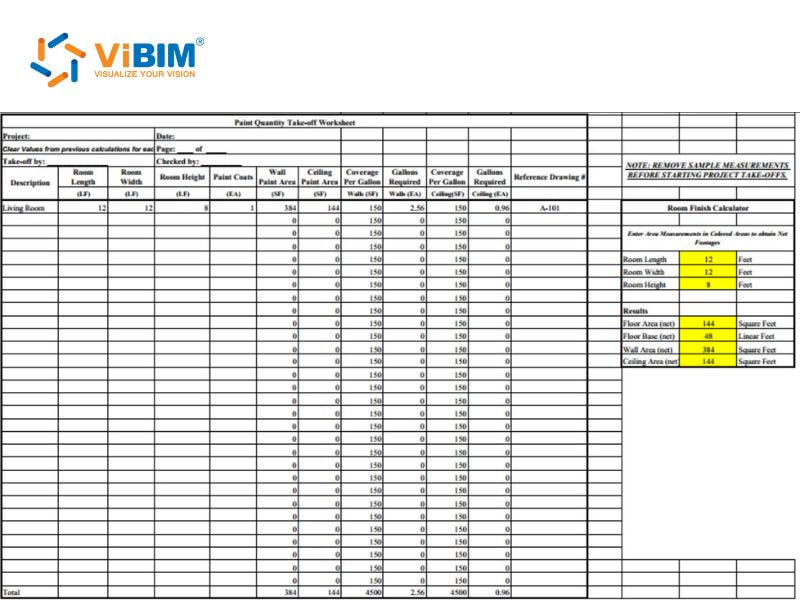

Manual quantity takeoff is the oldest method used to calculate construction materials and labor without specialized software. Estimators depend on printed blueprints or physical drawings to read dimensions, note details, and compute quantities based on their own experience and precision. Even with basic tools like Excel or Word, the process remains fully manual and demands consistency and focus.

This method involves several detailed steps carried out by the estimator:

- Reviewing the project scope, drawings, and specifications

- Measuring directly from paper plans using scale rulers and highlighters

- Recording data with handwritten notes or simple spreadsheets

- Applying manual formulas and calculations to define total quantities

Manual takeoff offers three benefits that rely on human experience and flexibility:

- Uses the estimator’s skill and judgment to handle complex details

- Provides a reliable check against automated results

- Requires minimal technical setup or software investment

However, the drawbacks appear clearly when project scale increases:

- Consumes significant time and effort for large or detailed drawings

- Exposes results to calculation or transcription mistakes

- Produces lower accuracy compared to digital methods

- Becomes difficult to update when any project data changes

Digital quantity takeoff

Digital quantity takeoff uses software and database applications to measure, quantify, and estimate construction materials directly from digital drawings or 3D models. Estimators can upload project files, click to measure areas or lengths, and instantly generate detailed reports. Since its early development in CAD-based systems, this method has become a standard tool for complex or large-scale projects that require accuracy and consistency. Selecting the best BIM software is crucial for ensuring these measurements are accurate and that the digital tools integrate seamlessly with the project’s data environment.

Digital takeoff can be divided into two main levels:

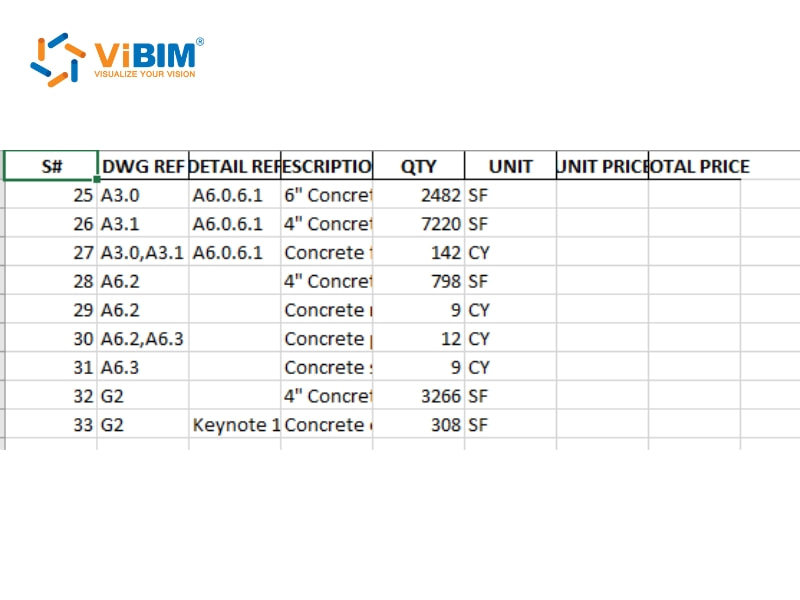

- 2D Digital Takeoff: Works with digital files such as PDFs or CAD drawings. Estimators use on-screen tools to click, trace, and measure elements, while the software automatically calculates lengths, areas, and volumes, and organizes the data into a structured list. This method is much faster than manual measurement and significantly reduces calculation errors.

- 3D Digital Takeoff (Model-Based Takeoff): Represents a more advanced stage built on Building Information Modeling (BIM). Estimators use intelligent 3D models in which every component, such as walls, beams, or pipes that contains embedded data on its dimensions, materials, and specifications. The QTO software automatically extracts these quantities from the model, forming the foundation of 5D BIM, where cost data links directly with the 3D design.

The process of digital takeoff involves four connected steps handled within the same software environment.

- Uploading digital plans or 3D models into the system

- Measuring quantities on-screen using automated or assisted tools

- Applying pricing formulas and cost databases for quick estimation

- Storing and sharing project data through cloud platforms for real-time collaboration

Digital takeoff offers four advantages that improve productivity and accuracy.

- Completes takeoffs faster with minimal manual work

- Reduces human error through automatic validation

- Keeps data organized for team access and review

- Cuts labor time and supports better decision-making

However, the method still presents three practical challenges.

- Requires proper training and familiarity with software tools

- Depends on clear, accurate input drawings or models

- Demands investment in licenses or subscriptions that may affect smaller teams

To visualize their differences more clearly, the comparison below outlines how each method performs in key aspects.

| Feature | Manual Takeoff | Digital Takeoff |

| Tools Used | Paper plans, ruler, calculator, spreadsheets | PDF or BIM models, takeoff software |

| Accuracy | Dependent on the estimator’s skill; prone to error | High precision through automation |

| Speed | Slow and repetitive | Fast and efficient |

| Collaboration | Paper-based, limited sharing | Cloud-based, easy collaboration |

| Best Use | Cross-checking estimates, small projects | Large-scale or fast-paced projects |

Hybrid quantity takeoff

A hybrid quantity takeoff method combines both manual and digital estimating techniques to leverage their strengths. This approach helps maintain accuracy and efficiency by applying different methods depending on the complexity and available data of each construction element.

A hybrid quantity takeoff involves the seamless integration of multiple takeoff methods tailored to the needs of each project.

- Digital takeoff is conducted for most components using software tools that automate measurement and calculation.

- Manual takeoff is applied to elements that require detailed attention or when digital plans are incomplete or unavailable.

- 3D or BIM-based extraction is used for parts of the project where 3D models are available.

- Quantities are adjusted and cross-verified through multiple methods to improve accuracy and completeness.

This approach offers five advantages that enhance project accuracy and flexibility.

- Accuracy is improved by combining manual expertise with the precision of digital tools.

- Efficiency is enhanced compared to purely manual estimating methods.

- Flexibility increases when handling both paper-based and digital project data.

- Manual efforts can focus on complex or critical items while routine tasks are automated.

- All project elements are covered more completely, reducing the risk of omissions.

However, there are still four challenges that may arise from blending different methods and data sources.

- Training and skill in multiple takeoff methods may be required.

- Data from various sources may create complexity in management and reconciliation.

- More time may be needed than with fully digital takeoffs if manual tasks dominate.

- Benefits depend on the availability and quality of digital project data.

Who is involved in a quantity takeoff?

A quantity takeoff involves professionals responsible for early project planning and cost estimation, as the collected data helps shape accurate budgets, proposals, and contracts. There are four key participants in this process, including:

- Quantity surveyors / cost estimators: Lead the takeoff process, measure quantities, and convert them into cost data.

- Architects and engineers: Provide drawings and technical details used to extract exact measurements.

- Project managers and construction managers: Coordinate teams, maintain data accuracy, and align results with project timelines and goals.

- Contractors and subcontractors: Conduct their own takeoffs to prepare bids, assign labor, and manage material use efficiently.

Additional professionals also contribute, depending on the project’s size and scope.

- Urban master planners and smart city designers

- Residential builders and renovators

- Civil, structural, mechanical, and transportation engineers

- Highway, rail, and utility contractors

- Landscapers and marine or offshore architects

Performing a quantity takeoff requires technical skill, attention to detail, and extensive experience. Many organizations rely on independent takeoff specialists to maintain accuracy, consistency, and efficiency throughout the entire estimating process.

How to do a quantity takeoff?

A quantity takeoff involves two main phases that work closely together: the input and the output. Readers can explore how each phase functions in detail in the next section.

The Initial Phase: Input Considerations

The input stage focuses on collecting and verifying all information supporting the quantity takeoff. Accuracy begins here, where data is reviewed, structured, and confirmed before any measurement starts. To ensure reliable results, estimators follow a series of preparatory steps that establish a solid foundation for the takeoff process:

- Review all project documents including drawings, specifications, and contracts to build a clear understanding of the scope and requirements.

- Feed design data into the takeoff system and verify its precision through design validation or model checking.

- Identify discrepancies or missing details early and coordinate with architects, engineers, or project managers to correct them.

- Structure data by dividing the project into smaller sections or assemblies such as floors, phases, or components for better organization.

Reliable input keeps all measurements aligned with the real project design. Any small mistake here can lead to major cost or scheduling problems later.

Output

Performing material takeoffs plays a vital role in the output stage of construction data management. This stage converts verified design data into measurable quantities that form the backbone of project documentation. Accurate takeoff results help project teams visualize what needs to be built and prepare the groundwork for planning, scheduling, and resource allocation.

The process follows a systematic sequence to transform validated information into clear, measurable outputs:

- Quantify materials and labor directly from approved drawings or digital models to reflect the actual project scope.

- Identify and classify each item with correct specifications, dimensions, and units to maintain consistency across project data.

- Cross-check quantities across different model views or drawing sets to eliminate duplication or omission.

- Organize and compile results into structured deliverables such as Bills of Quantities, material schedules, or quantity summaries for project documentation.

To better understand how these calculations are performed in practice, let us look at a simple example of a quantity takeoff on a masonry wall:

- First, calculate the net surface area of the wall (ft² or m²) from the structural drawings. When doing so, exclude any openings and avoid double-counting corners.

- Next, calculate the surface area of a single brick, including the mortar joint.

- Then divide the wall’s net surface area by the surface area of a single brick to determine the total number of bricks required.

- Finally, add a waste factor of about 2–10% to account for material loss or breakage.

This example illustrates how even a simple calculation can transform design data into meaningful quantities that directly support cost estimation and material planning. A complete and accurate output builds the foundation for reliable budgeting, confident decision-making, and successful project delivery.

What is included and not included in a quantity takeoff?

Quantity takeoffs typically cover measurable items that can be clearly defined and calculated from design data, including:

- Unit Count: Individual elements that can be counted, such as doors, windows, fixtures, or pieces of equipment.

- Linear Length: Materials measured by their length, including pipes, reinforcement bars, steel sections, or timber beams.

- Surface Area: 2D components like walls, floors, ceilings, or finishes are measured by area for finishing and material coverage.

- Cubic Volume: 3D elements such as concrete pours, excavation volumes, and earthworks that depend on depth and space.

- Weight: Materials like structural steel or backfill where total mass affects transport needs or load calculations.

- Prefabricated Materials: Factory-made components that are assembled on-site and form part of the permanent structure.

To avoid quantity takeoff mistakes, the estimator should be aware of certain materials and items that should not be included in the measured figures. Some of these values are addressed later during the overall cost estimation process. The data that is not included in quantity takeoffs includes:

- Transportation and delivery costs

- Loading and unloading expenses

- Scaffolding or temporary works

- Lapping, wastage, or offcuts

- Stripping and removal of formwork

Why is quantity takeoff important?

A quantity takeoff (QTO) is a cornerstone of construction planning and cost management. Its accuracy directly influences nearly every aspect of a project—from cost estimation and bidding to scheduling and procurement. A well-executed QTO ensures that teams have a clear, data-driven understanding of what resources are required, when they are needed, and how much they will cost. Below are the key reasons why quantity takeoffs are vital to project success:

- Accurate cost estimation, budgeting: A precise QTO provides a reliable basis for estimating and budgeting by defining exact material and labor quantities. This precision helps contractors submit realistic bids, control spending, and maintain financial confidence throughout the project.

- Competitive and profitable bidding: For contractors, a precise QTO allows them to create a bid that is low enough to win the job but high enough to be profitable.

- Better planning, scheduling, and procurement: A detailed QTO gives project teams the data they need to schedule construction activities effectively and plan material deliveries on time. It also supports procurement teams in sourcing materials efficiently, negotiating better prices, and preventing inventory delays or surpluses.

- Improved communication, collaboration, and documentation: A complete QTO acts as a shared reference for designers, engineers, contractors, and clients, keeping everyone aligned on material quantities and costs. This transparency reduces miscommunication and creates a consistent record for progress tracking, change management, and reporting.

- Enhanced risk management and reduced rework: A QTO encourages early design reviews, enabling detection of inconsistencies or missing details before work begins. Identifying potential issues early minimizes rework, reduces design conflicts, and maintains control over project scope, timeline, and cost changes.

- Increased efficiency and material optimization: A QTO promotes better use of materials by reducing overordering and waste. Accurate quantification leads to cost savings, faster construction, and more sustainable building practices, making projects both efficient and environmentally responsible.

How does ViBIM’s scan to BIM service ensure takeoff precision?

For renovation and retrofit projects, the accuracy of quantity takeoffs is often affected by outdated or missing “as-built” drawings. ViBIM’s Scan to BIM service helps solve this issue by utilizing professional point cloud modeling services to capture exact site conditions. ViBIM then processes and converts that raw data into a highly accurate as-built BIM model that reflects every detail of the existing structure.

This model serves as a reliable single source of truth for all quantity takeoffs, enabling clients to verify information such as room areas, wall surfaces, door quantities, and material volumes in finishing works. Beyond construction, accurate models are essential when implementing Scan to BIM for FM to maintain the asset throughout its lifecycle. ViBIM has completed many detailed projects that support clients in comparing and verifying these metrics directly from the BIM model.

Performing a quantity takeoff from a Revit model requires a deep understanding of building structures, software configuration, and careful control of parameters within each family. Not every parameter can be used for calculation, as some provide precise volume data while others are only suitable for reference. This level of technical understanding allows ViBIM to deliver accurate and practical quantity information for every project. Contact ViBIM today to discuss your project requirements and receive a complimentary quote for the best Revit BIM modeling services.

Frequently asked questions about quantity takeoff

What are the units for quantity takeoff?

Quantity takeoffs use standardized measurement units to accurately quantify different materials and project elements. The choice of unit depends on the type of item being measured and the project’s regional or industry standards.

- Length / Distance: Linear materials like pipes, cables, or beams are measured by length. Units include feet (ft), inches (in), meters (m), and centimeters (cm).

- Area: Surface materials such as flooring, roofing, or wall finishes are calculated by area. Units include square feet (sq ft), square inches (sq in), square meters (sq m), and square centimeters (sq cm).

- Volume: Materials occupying space, such as concrete, soil, or fill are measured by volume. Units include cubic feet (cu ft), cubic inches (cu in), cubic meters (cu m), and cubic centimeters (cu cm).

- Count: Individual elements such as doors, windows, fixtures, or switches are counted. Units include each (ea) and unit (unit).

- Weight: Heavy or bulk materials such as steel, rebar, or pipes are measured by weight. Units include pounds (lbs), ounces (oz), kilograms (kg), and grams (g).

- Time: Labor or equipment usage is measured by time. Units include hours (hr) and minutes (min).

- Currency: Cost data are presented in the takeoff summaries in the currency used. Units include dollars (USD), euros (EUR), or other local currencies, depending on project location.

What are the common mistakes during quantity takeoff?

There are five common mistakes that often occur during quantity takeoffs, and each one can impact the accuracy and reliability of project estimates.

- Rushing Measurements: Inaccurate scaling or dimension errors appear when measurements are rushed. Careful checking with digital tools helps prevent shortages and extra costs.

- Ignoring Design Changes: Outdated drawings produce incorrect quantities. Using updated software keeps takeoff data consistent with the latest design revisions.

- Overlooking Specifications: Skipping specification details can result in using wrong materials. Cross-checking every item with the latest documents ensures correctness.

- Neglecting Site Conditions: Failing to account for terrain or soil type reduces reliability. Regular site inspections make quantity estimates more realistic.

- Poor Collaboration: Weak coordination among teams leads to duplicate or missing items. Frequent communication and shared data platforms maintain accuracy.

What is the difference between a full detailed estimate and a quantity takeoff?

A quantity takeoff (QTO) focuses on measuring and listing all materials, labor, and equipment required for a project, while a full detailed estimate builds on that data to assign costs and calculate the total project budget. In short, QTO determines what is needed, and a detailed estimate determines the cost.

Below is a table comparing the two approaches:

| Aspect | Quantity Takeoff (QTO) | Full Detailed Estimate |

| Purpose | Identifies and measures materials, labor, and equipment needed for the project. | Provides a complete cost assessment, including all direct and indirect expenses. |

| Scope | Focuses on quantifying physical components only. | Includes QTO data plus pricing, labor rates, overheads, and profit margins. |

| Level of Detail | Detailed in quantities but excludes cost information. | Detailed in both quantities and costs, covering every project component. |

| Use | Basis for cost estimation, procurement, and planning. | Used for bidding, budgeting, and financial decision-making. |

| Output | List of measured quantities. | Comprehensive cost breakdown and total project estimate. |

The article has explained what is quantity take off and how it serves as the foundation of accurate construction planning and cost management. Each section discussed the process, key components, and the role of BIM in improving accuracy, collaboration, and data control. Common questions and mistakes were also clarified to help readers gain a clearer understanding of how quantity takeoffs work in real projects.

ViBIM focuses on providing BIM Modeling services from Point Cloud data (Scan to BIM), specializing in using Revit as the main authoring tool on the Autodesk platform. The company supports building surveyors, existing and as-built documentation, design, and engineering projects. Contact ViBIM today to discuss your project requirements and receive a complimentary quote for the best Revit modeling services.

Vietnam BIM Consultancy and Technology Application Company Limited (ViBIM)

- Address: 10th floor, CIT Building, No 6, Alley 15, Duy Tan street, Cau Giay ward, Hanoi, Vietnam

- Phone: +84 944 798 298

- Email: info@vibim.com.vn