Business Needs

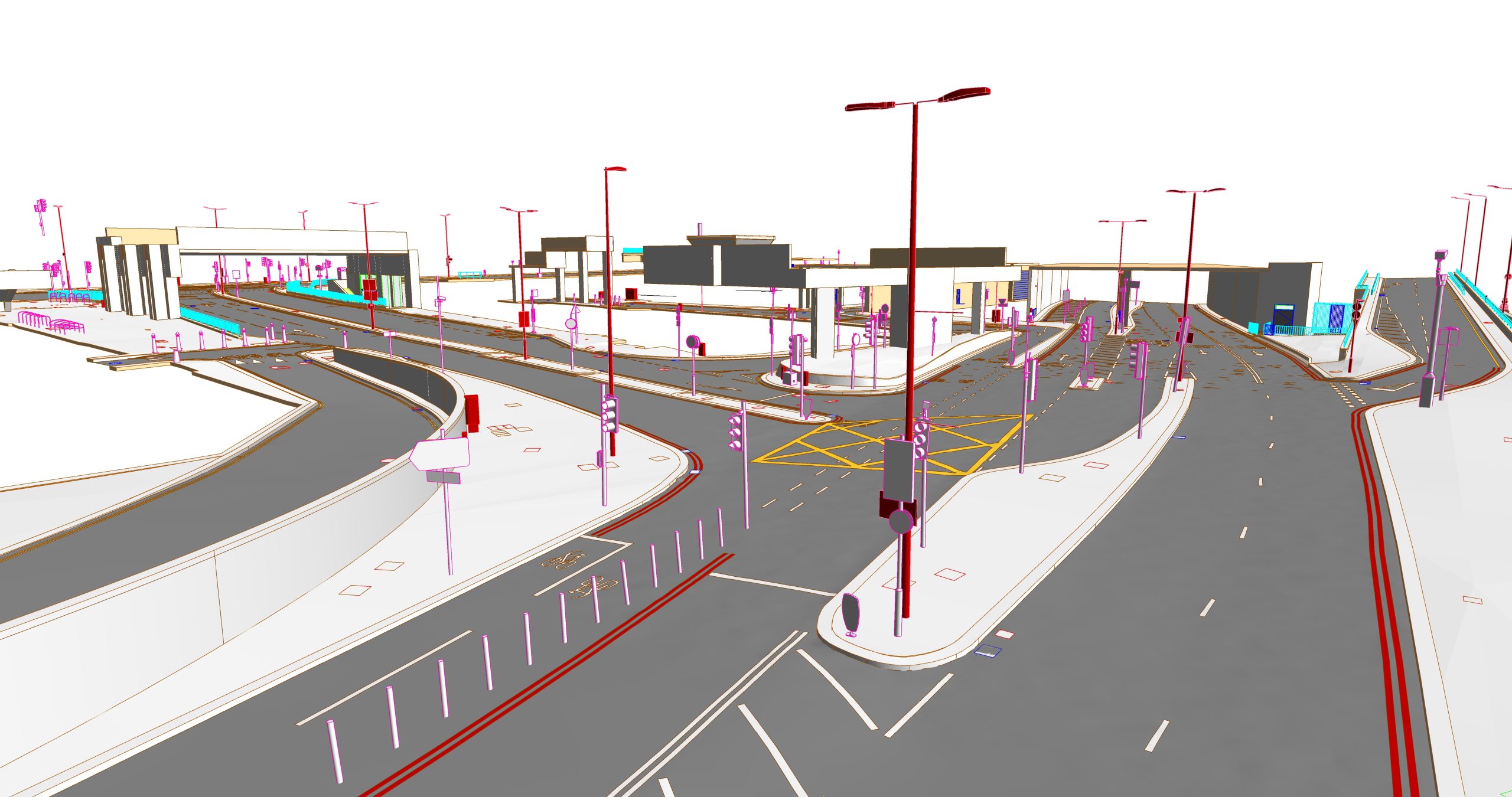

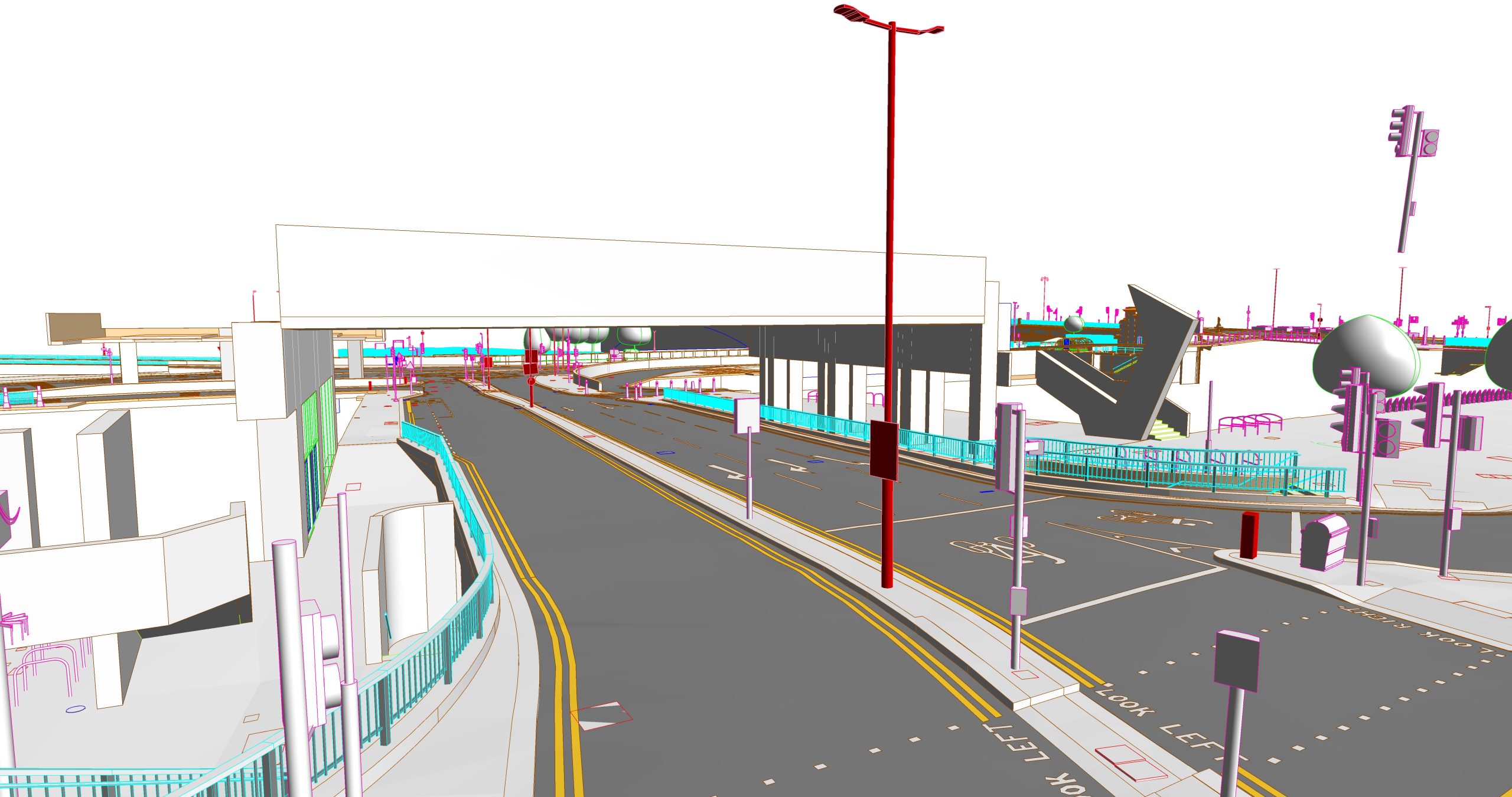

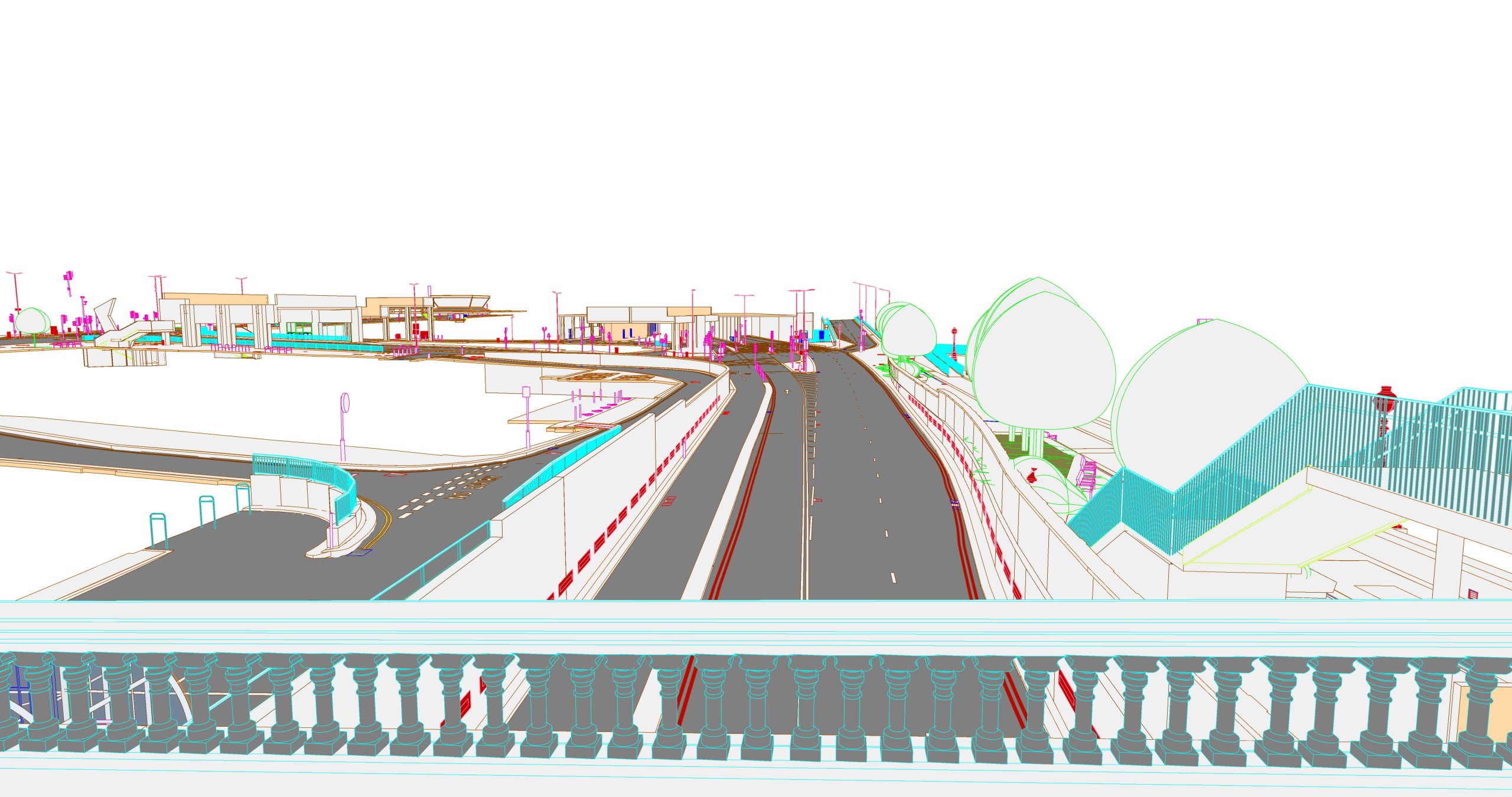

Project 380.UK was a topography-focused Scan to BIM project with a total site area of approximately 36,100 m². The modeling scope covered the entire site terrain (topo), including key elements such as roads, sidewalks, and landscape-related structures. The client commissioned this detailed LOD 400 topographic model to establish an accurate and up-to-date digital representation of existing conditions. The model was specifically intended to serve as a reliable information base for future design and development activities. This level of detail is a hallmark of leading Scan to BIM Services Providers, ensuring that subsequent planning and design decisions would be grounded on precise and comprehensive site data.

Key Objectives

- Develop a Future-Ready 3D Model: The core objective was to transform raw point cloud data into an intelligent 3D BIM model. This model needed to be robust and detailed enough to serve as a reliable baseline for all subsequent design and renovation projects.

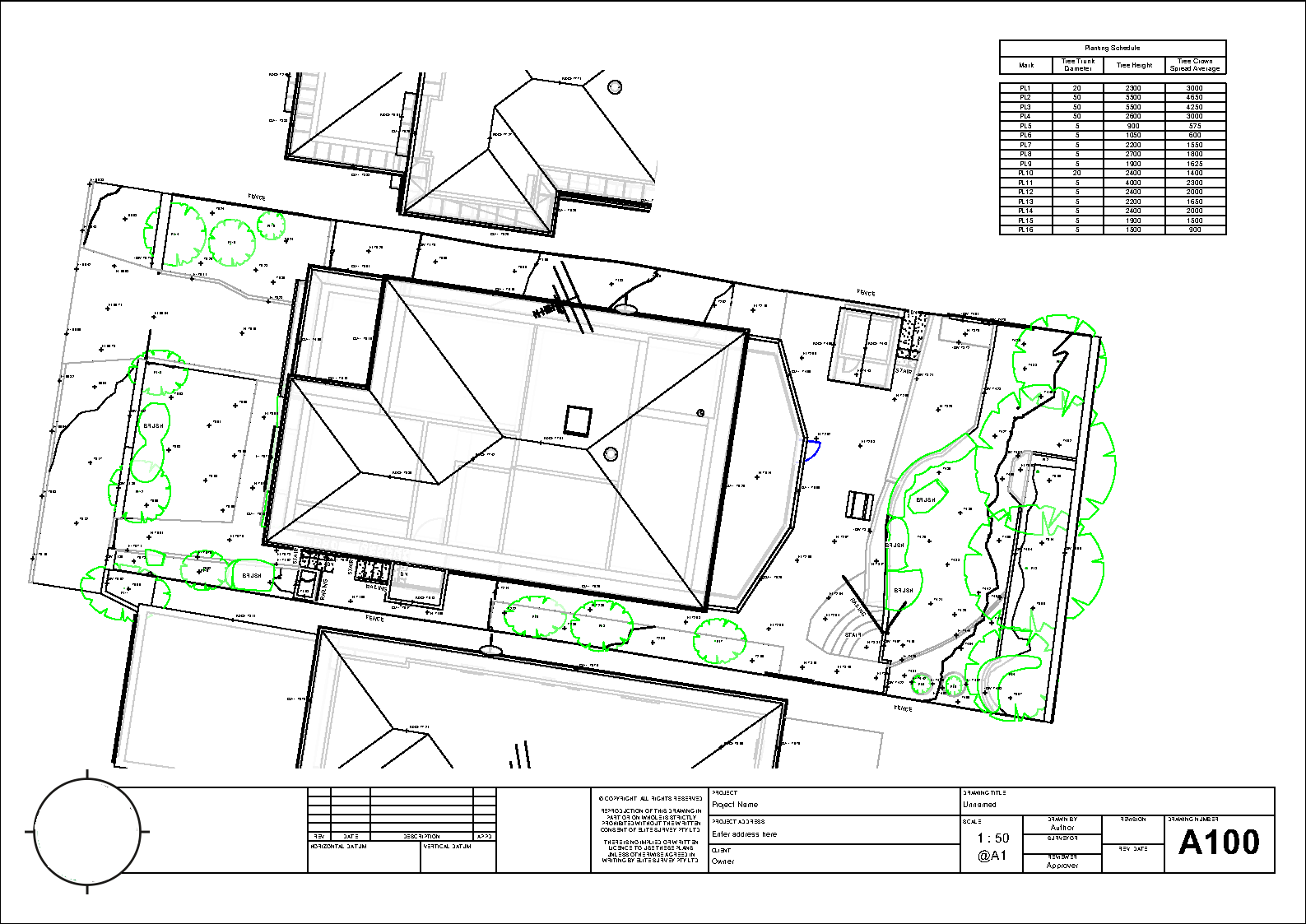

- Generate Archival 2D Documentation: From the completed 3D model, a full set of accurate 2D drawings was to be generated to support the client’s archival and documentation requirements, providing a clear and accessible record of the existing site conditions.

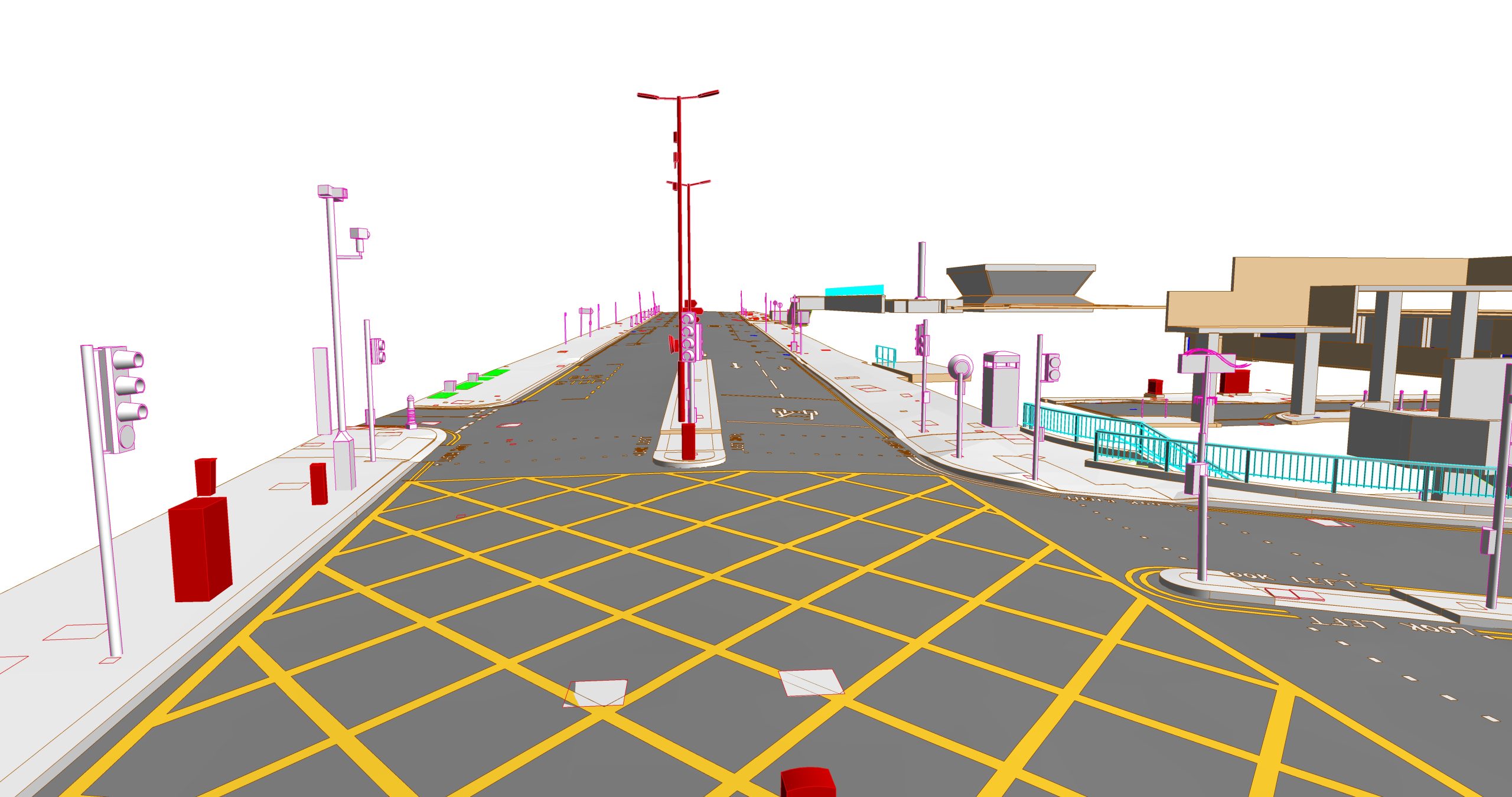

- Achieve High-Fidelity and Accuracy: A critical goal was to construct a complete model of all topographic and transportation infrastructure elements with a stringent deviation tolerance not to exceed ±25mm from the point cloud data. The model also had to meticulously adhere to all technical requirements regarding the architectural and structural composition specified by the client.

Challenges

- The requirement to develop the model to a LOD 400 standard presented a significant challenge. This demanded not only modeling elements with specific, accurate assembly information but also ensuring that this high level of detail perfectly matched the real-world conditions captured in the point cloud data.

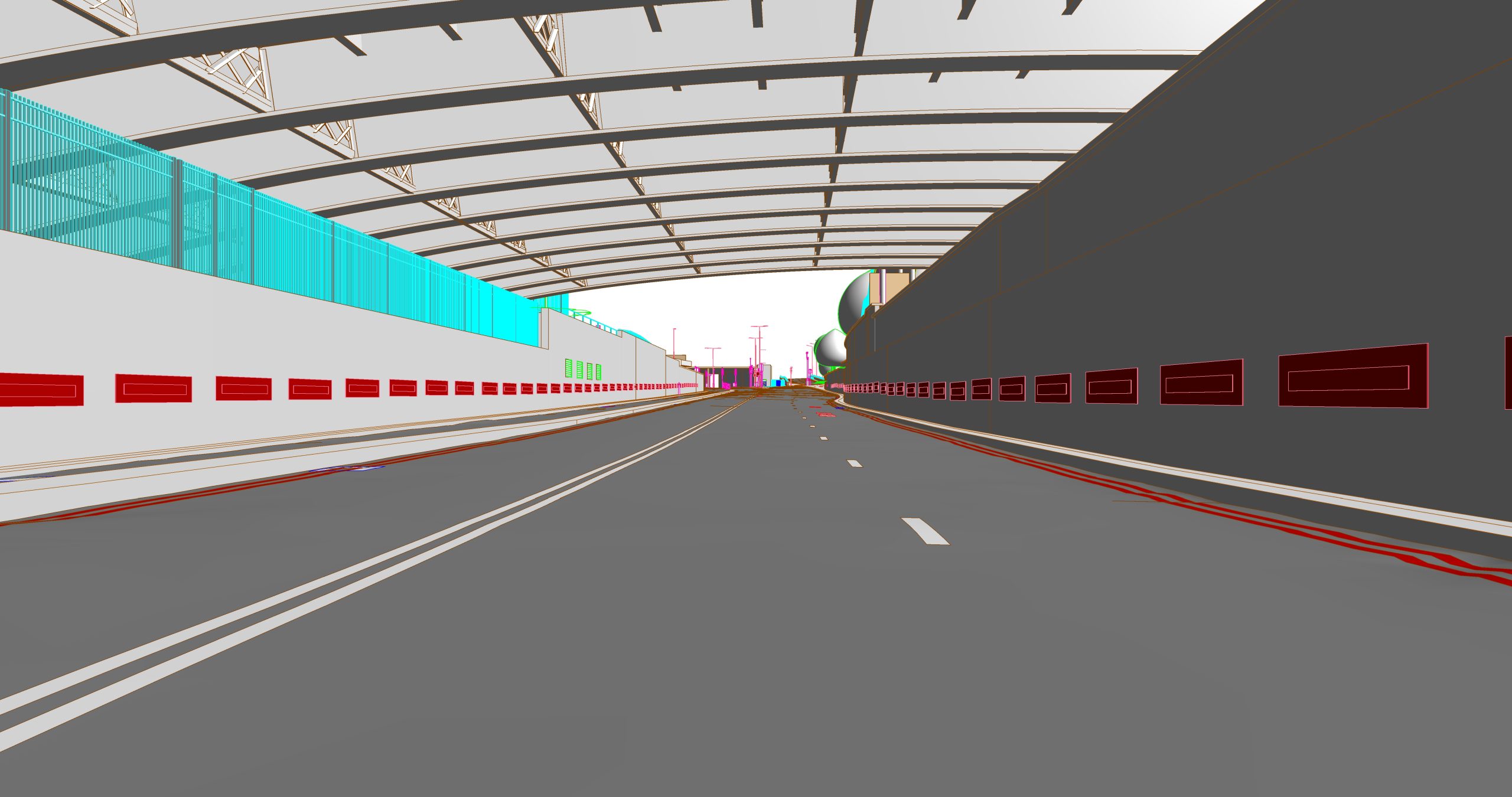

- The site’s intricate topography and interconnected transportation network had to be modeled into a single, continuous, and seamless surface. Achieving this without data corruption or geometric inaccuracies across such a large area required an advanced modeling strategy.

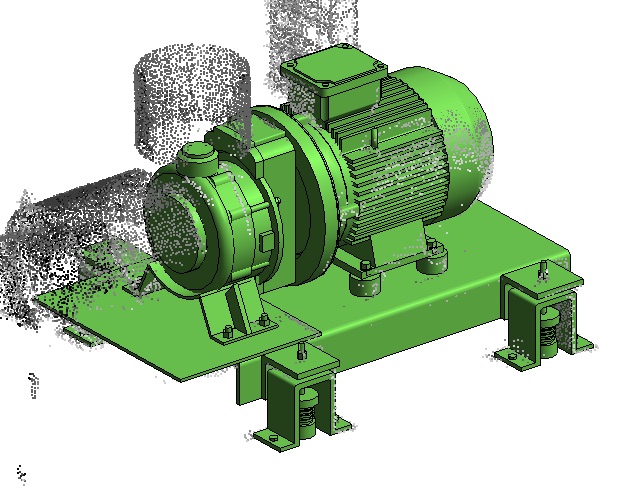

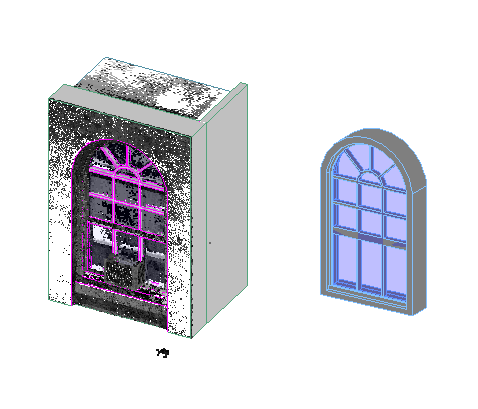

- The project scope included a wide variety of unique site objects and features. Modeling each of these and creating the corresponding custom Revit families was identified as a potentially time-consuming bottleneck that could impact project timelines.

- To ensure the model would be useful for future analysis, it was crucial that all the different surface types (e.g., pavement, grass, sidewalks) were modeled with clearly defined and logically separated materials. This was essential for enabling accurate quantity takeoffs and effective asset management.

Our Solutions and Approach

- To efficiently handle the complex and expansive terrain, our team employed a strategic segmentation method. The entire site was broken down into smaller, manageable topographic sections. Each piece was modeled independently to maintain performance and precision, and then all sections were meticulously joined together to form one complete and seamless as-built model.

- ViBIM utilized a proprietary in-house software tool to overcome the time-intensive challenge of loading numerous custom families. This automation allowed our team to batch-load multiple families at once, dramatically accelerating the workflow and reducing manual modeling time.

- We implemented a rigorous quality control process to guarantee accuracy. Specialized internal software was used to conduct a direct deviation analysis between our BIM model and the source point cloud, ensuring every modeled element was within the required tolerance.

- The structural and compositional integrity of objects was verified using detailed section views within Revit and specialized component inspection software.

- To ensure the precise identification of all materials, our team went beyond the point cloud data. We meticulously cross-referenced information from client-provided site photographs with satellite data from sources like Google Maps, allowing us to accurately identify, define, and apply the correct materials throughout the model.

Business Impact

- Creation of a Definitive As-Built Model: Our service delivered an accurate and reliable 3D as-built model of the existing site, completely eliminating the potential for errors that arise from traditional manual surveys. This model now serves as the single source of truth and a critical foundation for all future works.

See how we master massive-scale sites with construction-ready precision. Our Revit Modeling Services are engineered to deliver a reliable foundation for any project.