Business Needs

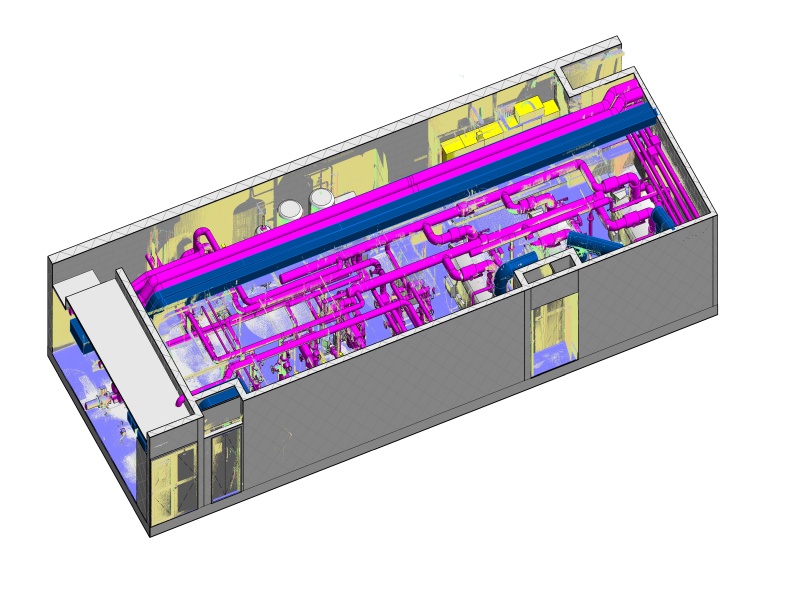

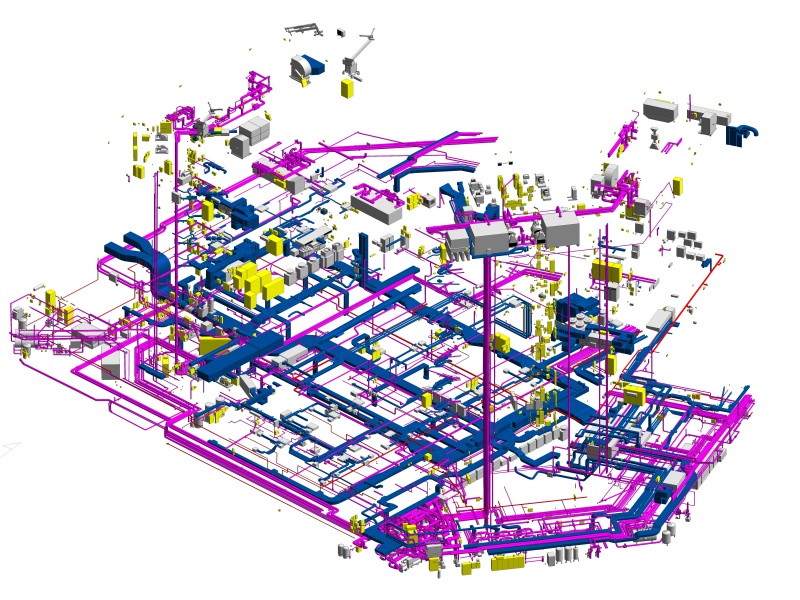

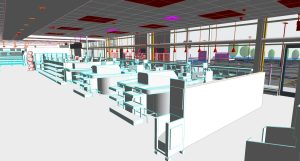

“701.UK” is a prominent office building located in the western region of the UK. The modeling scope includes the entire interior and exterior of the main building, MEP systems, façades of adjacent buildings, as well as the surrounding topography (topo).

Key Objectives

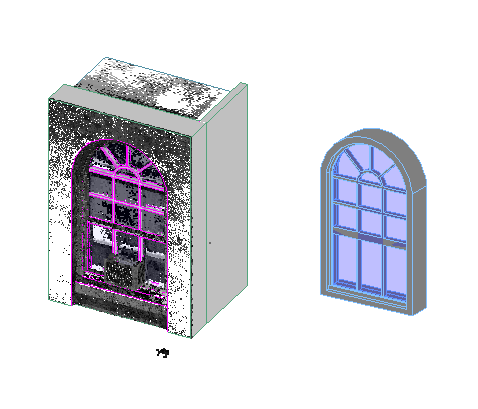

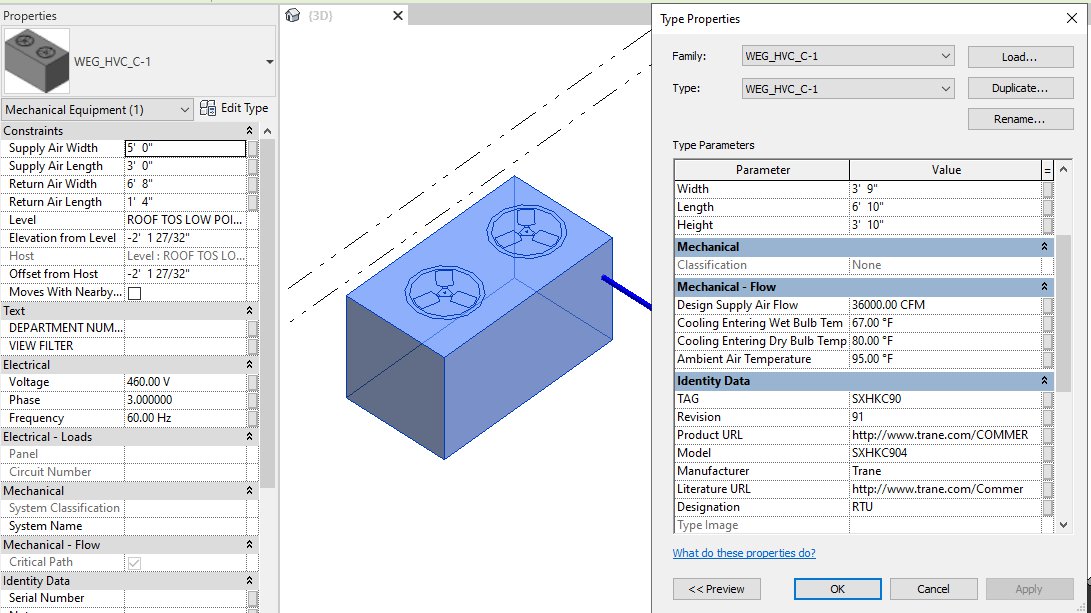

- Develop a 3D model from Point Cloud data using scan to bim services to support renovation processes.

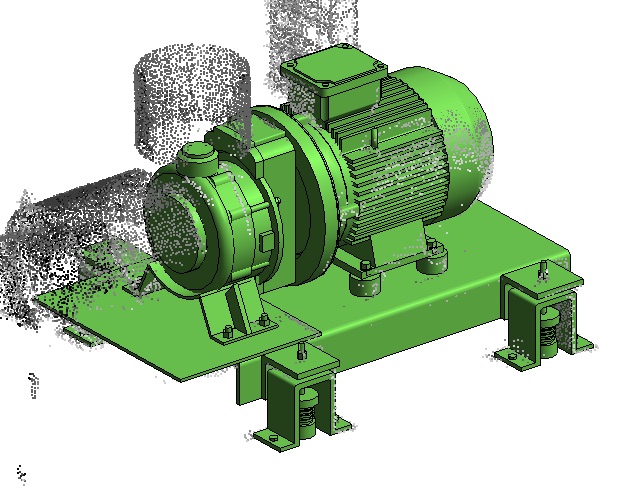

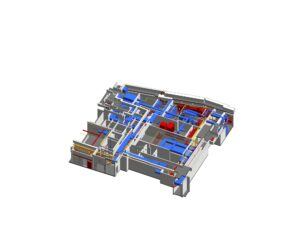

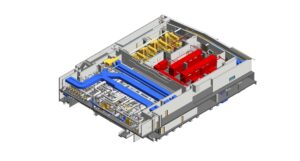

- Construct a comprehensive MEP model with an accuracy tolerance within ±15mm, strictly adhering to technical standards and physical configurations of equipment, ductwork, piping, cable trays, etc., based on shop drawings or manufacturer technical documents. The model accurately reflects design requirements, facilitating seamless coordination with other disciplines (architecture, structure).

Challenges

Architecture (ARC):

- Due to the large scale of the project, the model had to be split into three independent files: Architecture (ARC), Structure (STR), and MEP, creating difficulties in ensuring consistency and logical linkage between these segmented models.

- Ensuring correct material assignments for wall elements based on detailed data provided by the client.

MEP:

- Estimate: Estimating was challenging because of limited input data for MEP—only PDFs and exterior photos were available, making it difficult to assess interior spaces without detailed floor plans, sections, or as-built models. Estimating MEP quantities, suspended ceiling locations, object density, number of service shafts, and equipment-dense areas (e.g., plant rooms, corridors) was problematic.

- MEP Modeling: Simultaneous execution of this project and another similar one for the same client under tight deadlines demanded strong resource management and optimized coordination.

- Large volumes of Point Cloud data required substantial processing time before being usable for modeling.

- Poor Point Cloud quality in basement areas complicated accurate identification of existing ventilation systems.

- The complexity of MEP systems in high-rise buildings—with numerous systems (HVAC, electrical, plumbing, fire protection) and dense piping and duct networks sharing limited space—posed significant challenges.

- Accurately determining details of existing MEP components, including size, material, and connectivity, was highly challenging.

- Large rooftop plant rooms generate large service shafts connecting down to basements within tight service shafts, complicating collection of high-quality Point Cloud data.

- High object density in complex zones like basements, rooftops, and service shafts combined with low Point Cloud quality hindered full, precise modeling within the project timeframe.

QA-QC:

- Effectively controlling quantity and quality of MEP objects within limited QA-QC timeframes was challenging due to the large volume (thousands of objects per system including ducts, pipes, fittings, equipment, cable trays, valves, sensors), diverse object types, geometries, and parameters, combined with multi-level building and shaft complexities.

Our Solutions and Approach

Architecture (ARC):

- Model segmentation: Established a unified project coordinate system for all three model components. Used Shared Coordinates to ensure accurate relative positioning between Architecture, Structure, and MEP Defined clear workflows for model exchange and updates. Assigned ownership of objects to each model at project outset. Linked all models into a Federated Model for coordination and overall clash detection. Regular clash checks between Architectural and Structural models in Revit and Navisworks identified and resolved spatial and connectivity issues.

- Material verification: Established a material verification workflow to ensure all wall elements are correctly assigned materials per client requirements. Employed filters, schedules, and TrueView for material review and confirmation.

MEP:

- Estimate: To overcome limited input data, ViBIM leveraged benchmarking against completed similar projects and analyzed project-specific features such as area, building type, and MEP system density. This experience allowed close-to-reality time and resource estimation for each discipline (HVAC, Electrical, Plumbing, etc.).

- MEP Modeling: Implemented clear task allocation and rigorous supervision to ensure all team members understood goals and complied with quality standards.

- Enhanced communication and clarification: ViBIM emphasized ongoing information exchange and specification clarification throughout project delivery. Periodic reviews aligned team understanding and encouraged pursuit of optimal solutions.

- Modeling optimization: To handle complex MEP density and suboptimal Point Cloud quality, ViBIM developed parametric Families for similar objects, accelerating modeling. Dedicated personnel modeled service shafts and line-route systems, integrating Navisworks clash detection during Revit modeling to minimize errors.

QA-QC:

- Multi-layered quality control and technology application: To assure MEP object quality and quantity within constrained QA-QC timeframes, ViBIM applied multi-step review processes including sectional views, Navisworks checks, and proprietary Point Cloud analysis tools. Optimizing internal tools and smart Point Cloud analysis increased inspection efficiency and speed.

Business Impact

- Improved accuracy of cost and time estimates: By applying lessons from similar projects and analyzing building-specific features (type, area, MEP system density), ViBIM provides more precise estimates for project duration and resources, enabling stakeholders to plan effectively and avoid unnecessary cost overruns and delays.

- Enhanced model quality and reliability: The modeling process (MEP Modeling) executed by experienced staff (supervising junior personnel), adhering to ±15mm tolerance and technical standards. Use of parametric Families and internal tools created detailed, accurate models minimizing errors and potential clashes, ensuring high-quality deliverables.

- Guaranteed highest deliverable quality: A rigorous QA-QC workflow with multiple review layers (sectional, Navisworks, Point Cloud analysis) combined with supportive tools enabled ViBIM to detect and fully rectify issues prior to delivery, ensuring optimal model quality that meets project requirements.

- Provided valuable visual and data outputs for later project stages: The detailed BIM models supplied by ViBIM support not only design and construction phases but also add long-term value for operation and maintenance. Accurate location and specification data facilitate easier, more efficient management, maintenance, repairs, and system upgrades over the facility’s lifecycle.

Explore our Revit Modeling Services to see how we bring precision and clarity to even the most complex building projects.