Business Needs

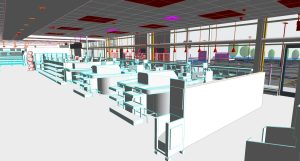

This project involved creating a detailed as-built model for a single-floor supermarket in the United States, covering an extensive area of 14,501 m². A primary requirement from the client was the development of highly accurate and intelligent Revit families tailored specifically for facility management. The focus of this case study is a critical excerpt from that larger project: the creation of a sophisticated butterfly valve family. The client required this component to be modeled with exhaustive technical specifications and flexible, dynamic parameters to support ongoing operational and maintenance activities throughout the building’s lifecycle.

Key Objectives

- Standards Compliance: The family had to comply with relevant industry standards (e.g., flange dimensions, clearance requirements, installation spacing) as well as project-specific BIM Execution Plan requirements to ensure accuracy, interoperability, and reliability in downstream workflows, a common requirement for professional Scan to BIM Solutions.

- Comprehensive Technical Data: A core objective was to embed the family with complete technical specifications, including precise dimensions, material information, pressure ratings, and flow rates. It also needed to contain manufacturer data and product codes to support accurate calculations, system analysis, and the generation of detailed schedules.

- Performance Optimization: The family had to be constructed as a lightweight element to prevent it from degrading the performance of the main Revit project file, ensuring smooth and efficient workflows for all users.

Challenges

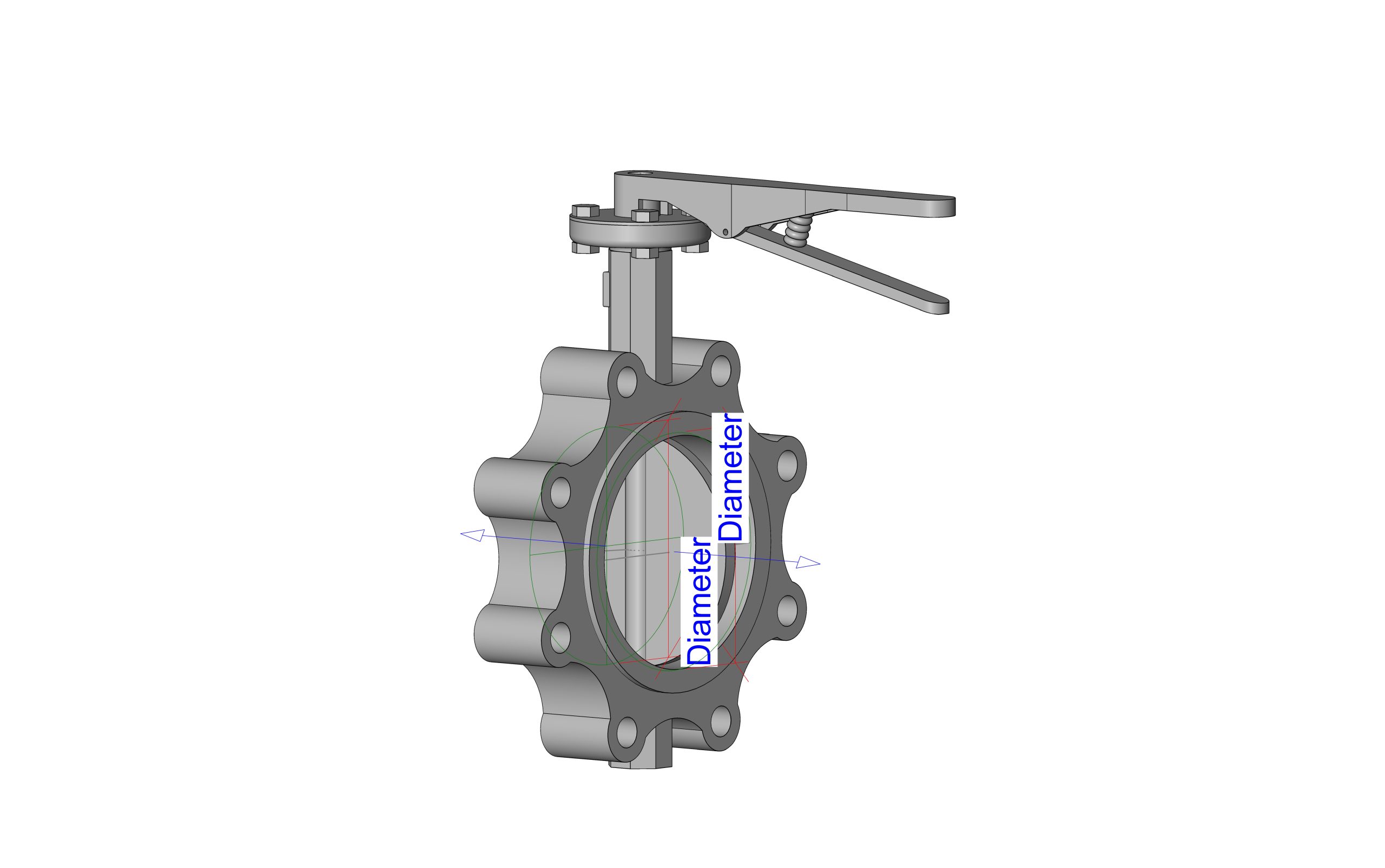

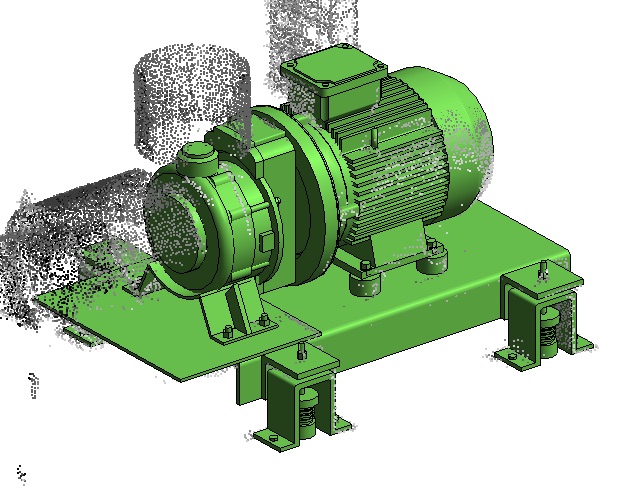

- Geometric Complexity: Butterfly valves contain intricate details and moving parts, such as the valve disc and handle. Modeling these components accurately required advanced 3D modeling skills to ensure the final family was both visually correct and functionally representative.

- Parameter Management: A significant challenge was defining and managing a wide array of geometric and informational parameters in a logical structure. The goal was to ensure the family was highly flexible and customizable without becoming overly complex or difficult for the end-user to manage.

- Pipe Connectivity: Establishing precise MEP connectors was critical for functionality. These connectors had to be configured with the correct system classifications, flow direction, and pressure information to guarantee seamless integration into the larger MEP system and to enable accurate engineering analysis.

- Performance and File Size: There was a need to strike a careful balance between the level of detail (LOD400) and the family’s file size. An overly detailed component could negatively impact the performance of the overall project model, particularly when used in large numbers.

- Standards Compliance: The family had to comply with relevant industry standards (e.g., flange dimensions, clearance requirements, installation spacing) as well as project-specific BIM Execution Plan requirements to ensure accuracy, interoperability, and reliability in downstream workflows.

- Advanced Revit Family Editor Expertise: The creation of such a dynamic and data-rich family demanded an in-depth, expert-level understanding of the Revit Family Editor environment, including the proficient application of work planes, reference lines, constraints, lookup tables, and other advanced concepts.

Our Solutions and Approach

To meet the project’s demanding requirements, ViBIM’s team implemented a systematic and technically rigorous approach, ensuring the final deliverable was precise, functional, and highly optimized. Our process focused on creating a robust foundation for the family, enabling both flexibility and stability.

- Detailed Planning and Scoping: Before any modeling began, we outlined the precise requirements for the family’s geometry, parameters, connection points, and intended use case. This foundational step involved identifying all standard dimensions and the necessary variations to ensure the family would be versatile enough to meet diverse project scenarios.

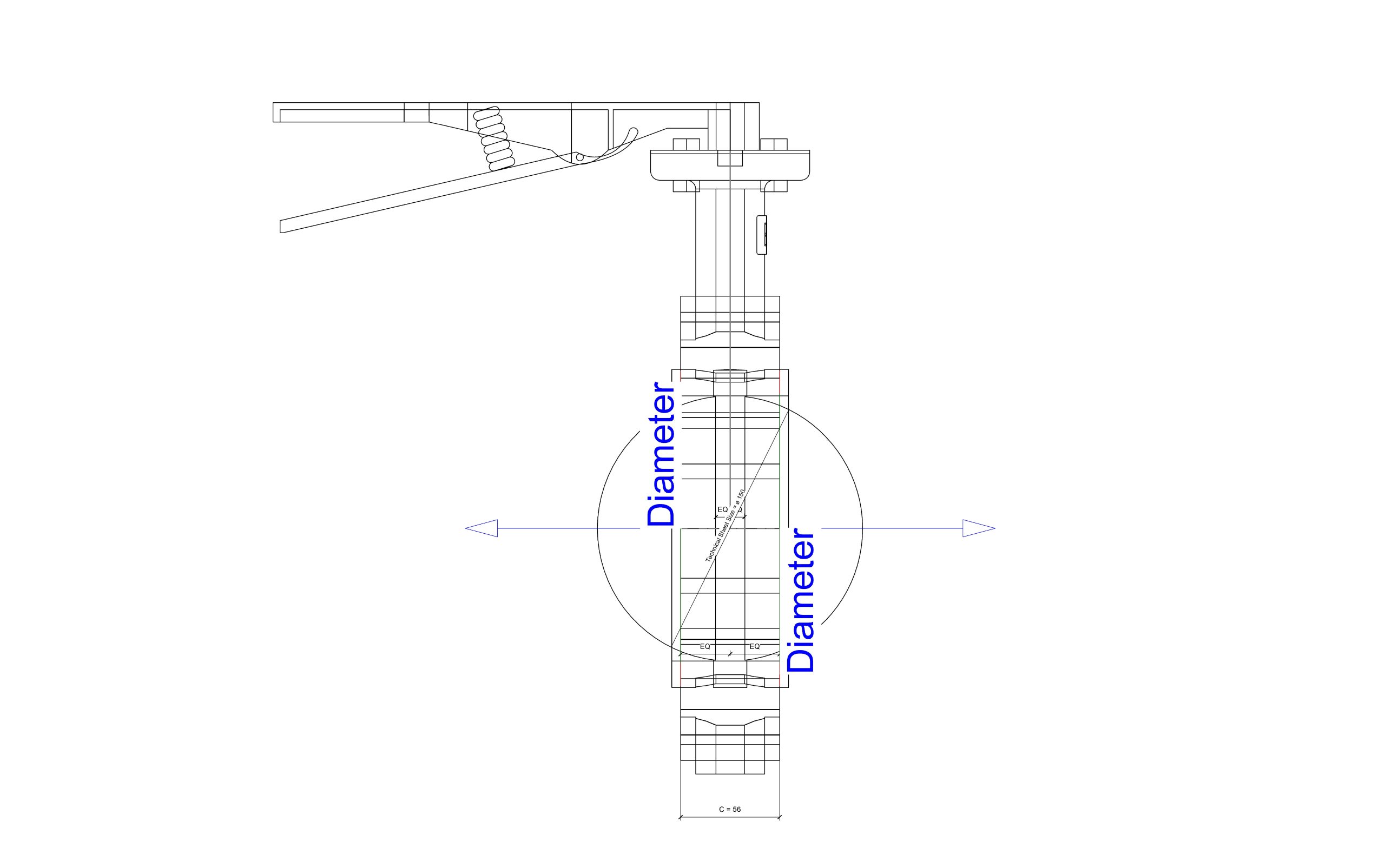

- Effective Use of Reference Planes and Constraints: Recognizing that a robust parametric framework is the backbone of any high-quality Revit family, we meticulously established reference planes and constraints. This framework was engineered to control the valve’s core dimensions and geometry, guaranteeing stability and predictable behavior when parameters were adjusted.

- Nested Family Methodology: To manage complexity and enhance functionality, we employed a nested family approach. Individual components of the valve, such as the handle, body, and flange, were created as separate families and then nested into a single, complete host family. This method allows for greater control over the visibility and articulation of each part.

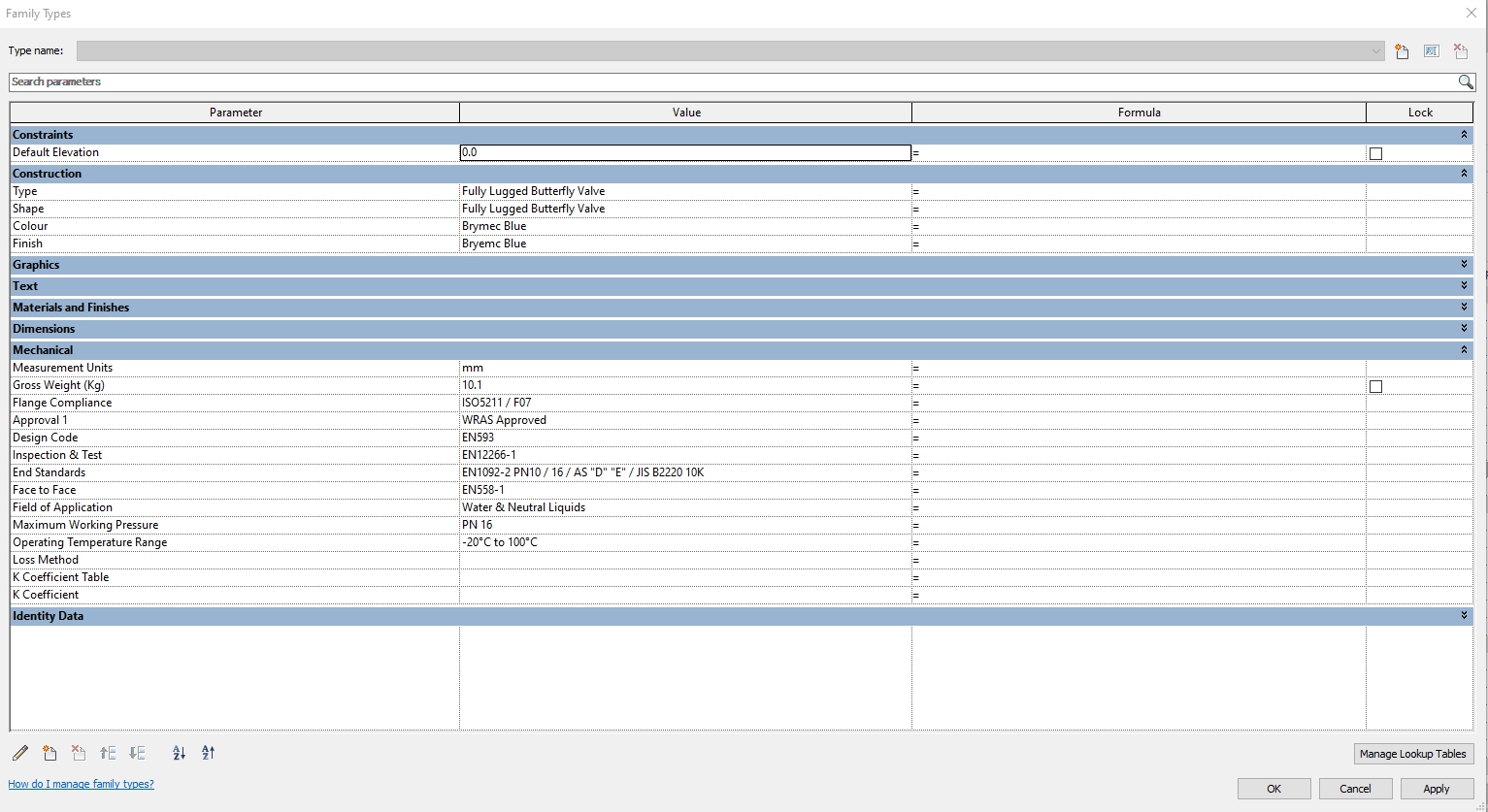

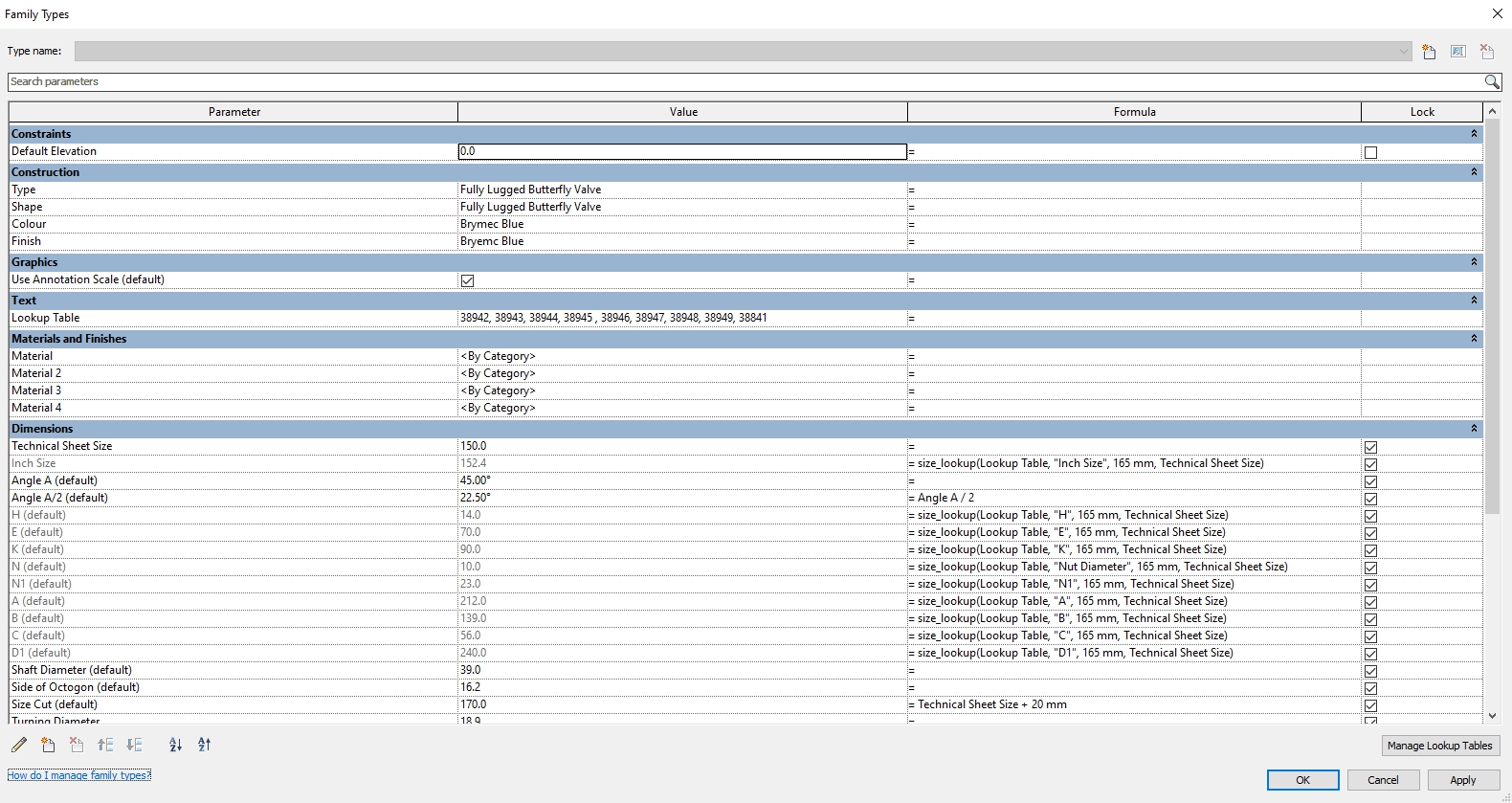

- Clear Parameter Classification: All parameters were logically categorized into clear groups (e.g., Dimensions, Technical Data, Materials, Visibility) for intuitive management. We made strategic use of Type and Instance parameters to control which attributes would be uniform for all valves of a certain type and which could be modified for individual instances in the project.

- Geometry and Performance Optimization: We focused on creating a lightweight yet visually accurate model by:

- Minimizing Complexity: Modeling only the essential details required for functional and visual purposes, avoiding overly intricate modeling of non-critical or internal components.

- Judicious Use of Void Forms: Employing void forms efficiently to create necessary openings and cuts without adding unnecessary weight to the family.

- Implementing Visibility Parameters: Assigning visibility controls to secondary components, such as the valve handle, allowing them to be turned off at lower levels of detail (Coarse/Medium) to improve model performance.

- Precise MEP Connector Setup: To ensure seamless integration into piping systems, MEP connectors were precisely configured. We verified that each connector was correctly positioned, oriented, and assigned the proper attributes for system type, flow direction, and pressure, enabling accurate system analysis and calculations within Revit.

- Thorough Quality Assurance and Testing: Upon completion, the family underwent rigorous testing in a sample project environment. We verified all functionalities, including its ability to resize correctly, connect flawlessly to various pipe types, display accurately across different levels of detail, and report correct parameter data.

- Referencing Standard Libraries: Our team researched existing butterfly valve families from leading manufacturers and reputable BIM libraries. This analysis provided valuable insights into best practices for constructing and managing complex, data-rich families, which we incorporated into our own workflow.

- Implementation of Lookup Tables: For valve types with numerous standard sizes, we integrated lookup tables. This powerful feature automates the process of populating the correct dimensions and technical data based on a single input parameter, such as the nominal diameter, drastically improving user efficiency and reducing the risk of error.

Comprehensive Documentation: Finally, we produced clear documentation for the family, outlining its intended use, a guide to its key parameters, and any operational limitations. This ensures that all future users can understand and deploy the family effectively and consistently.

Business Impact

The successful delivery of this detailed Revit family provided significant and lasting value to the client, impacting everything from model reliability to long-term asset management.

- Enhanced Model Quality and Reliability: The delivery of a high-quality, reliable butterfly valve family helped minimize errors, reduce clashes, and optimize space utilization within the digital model. This creates a trustworthy as-built model that serves as a dependable single source of truth for all project stakeholders.

- Improved Collaboration and Communication: By providing an intuitive, data-rich 3D component, we empowered project teams to better understand the design, improve coordination between disciplines, and make faster, more confident decisions.

- Advanced Analysis and Simulation: The comprehensive technical parameters embedded within the family serve as a crucial database for advanced system performance analysis, enabling the client to optimize operational efficiency and reduce energy consumption.

- Effective Long-Term Asset Management: The detailed information within the Revit family is directly applicable to the facility management phase. It provides the data needed for efficient asset tracking, preventative maintenance scheduling, and comprehensive lifecycle management of the equipment.

- Strengthened Professional Image: The use of intelligent, high-quality BIM families demonstrates a commitment to technical excellence and enhances the client’s reputation for precision and innovation within the industry.

This is the granular expertise your projects deserve. Scale your team with our Revit Model Outsourcing to ensure every component is built for the long term.