Business Needs

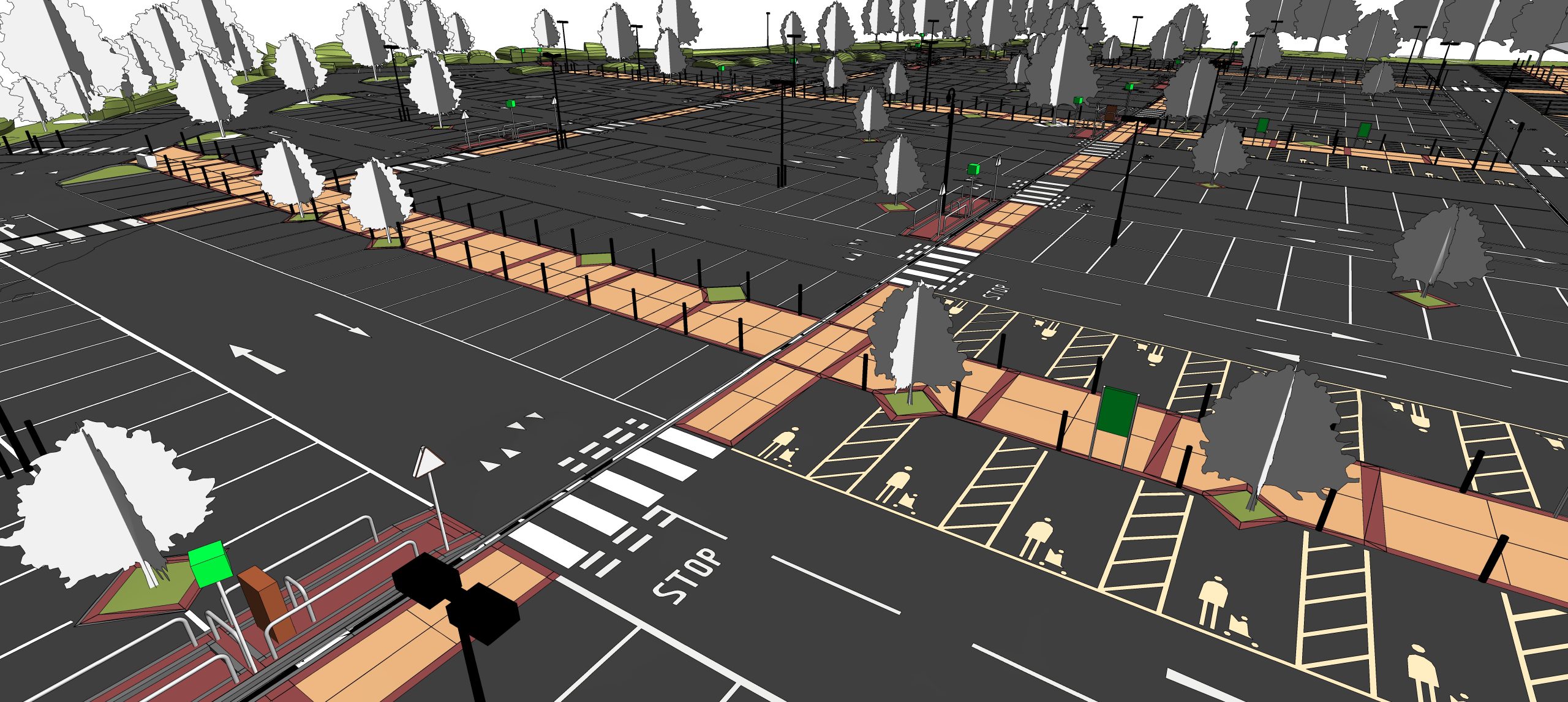

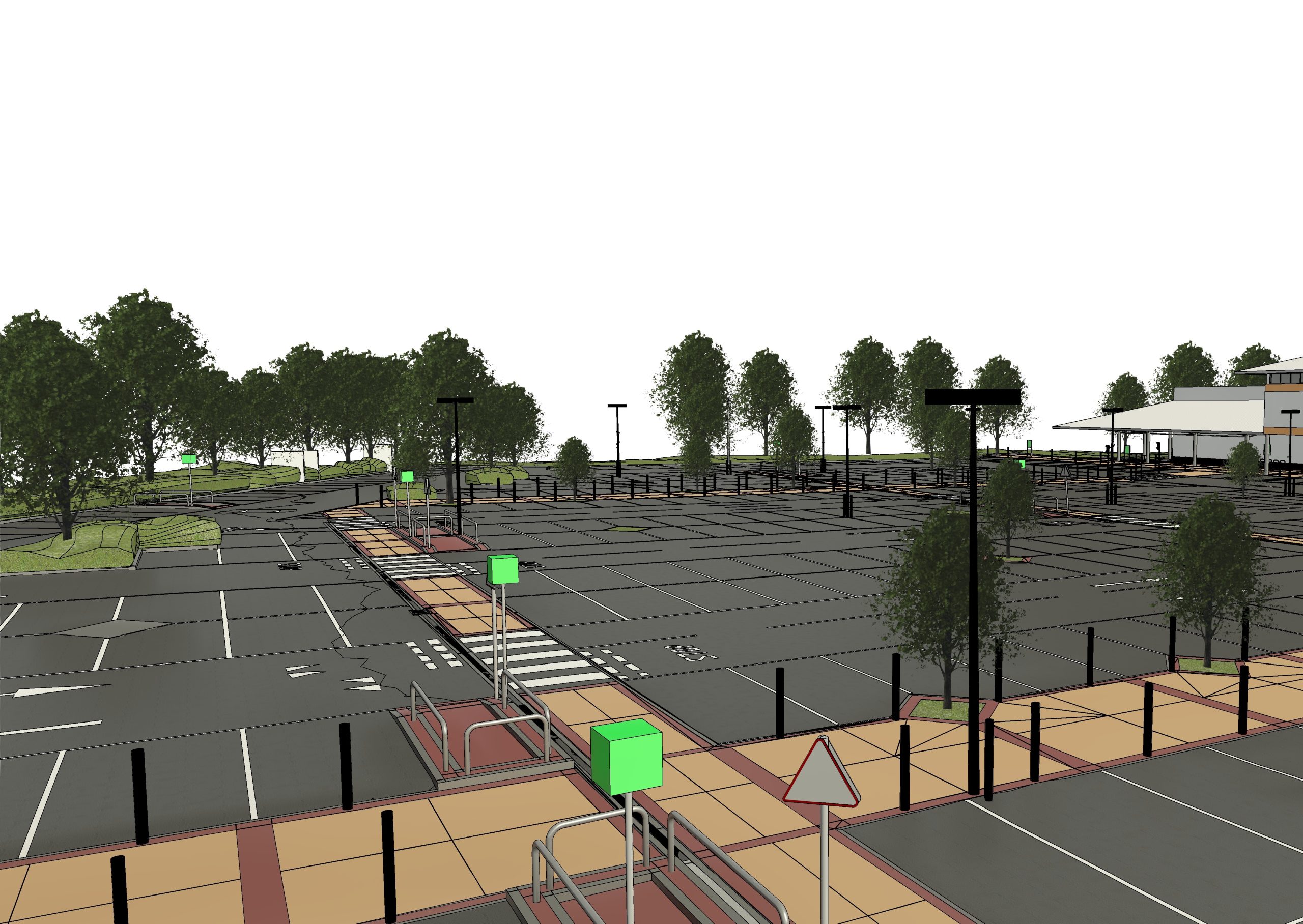

The 385.UK project involved a comprehensive topographic survey of a large site, spanning approximately 43,000 square meters in one floor. The primary scope was to transform raw point cloud data into a detailed and intelligent as-built model encompassing the entire topography of the area. This included modeling key infrastructure and landscape elements with high precision, such as roadways, sidewalks, and associated structures like lamp posts, signage, drainage systems, and road markings. The resulting model was intended to provide a highly accurate digital foundation, serving as critical as-built information to support future design and development initiatives on the site.

Key Objectives

- Develop a detailed 3D as-built model from point cloud data to serve as a reliable foundation for future design and renovation projects.

Construct a comprehensive model of all topographic features and transportation infrastructure elements, ensuring a strict modeling tolerance of no more than ±25mm.

The model also needed to adhere to the client’s specific technical requirements regarding the architectural and structural composition of all captured elements.

Challenges

- High Level of Detail (LOD 400): Modeling to a high Level of Detail (LOD 400) was required, demanding maximum alignment with the point cloud data while preserving the structural and compositional accuracy of each object.

- Seamless Topographic Surface: The extensive parking lot system and surrounding terrain needed to be modeled as a single, seamless, and unified topographic surface, which presented significant data handling and modeling challenges.

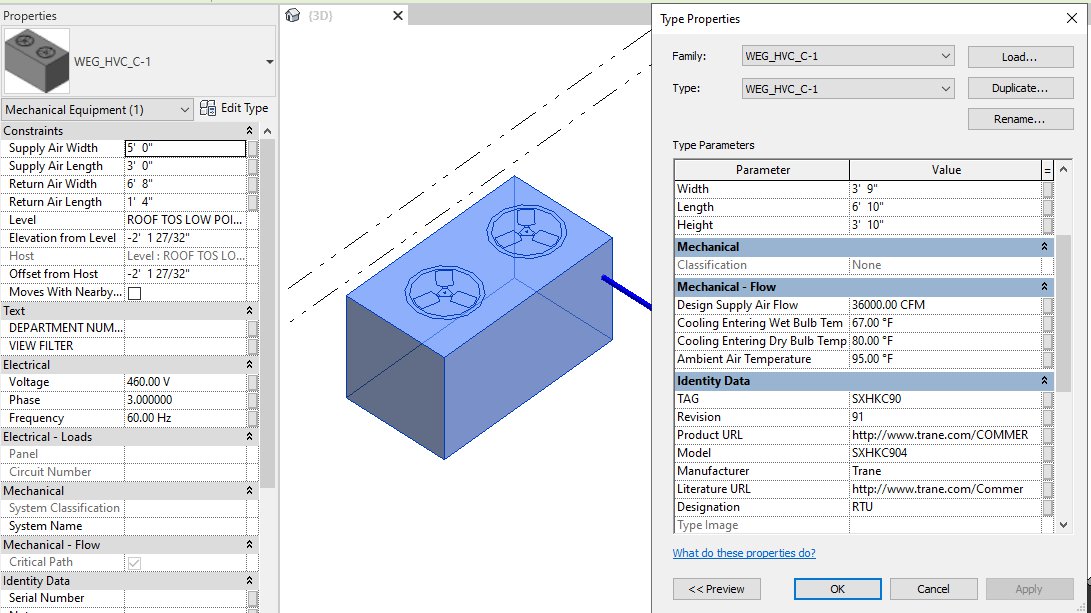

- Complex Family Creation: The project involved a vast number of diverse objects, each requiring the creation and loading of custom Revit families, a process that was potentially time-consuming and could impact project timelines.

- Material and Surface Differentiation: Differentiating and logically separating various surface types, such as pavements and terrain, with distinct material assignments was critical for facilitating accurate quantity takeoffs, material management, and further technical analysis.

Our Solutions and Approach

- Strategic Topographic Modeling: To efficiently model the large parking system and surrounding area, our team adopted a segmentation approach. We divided the extensive topography into smaller, manageable, independent sections. Each section was modeled individually before being precisely stitched together to form a single, seamless, and continuous terrain model, ensuring data integrity and model performance.

- Custom Tool for Workflow Acceleration: To address the challenge of loading numerous custom families, ViBIM developed a proprietary tool capable of batch-loading multiple families simultaneously. This innovative solution significantly reduced manual effort and accelerated the modeling timeline, directly tackling a major workflow bottleneck.

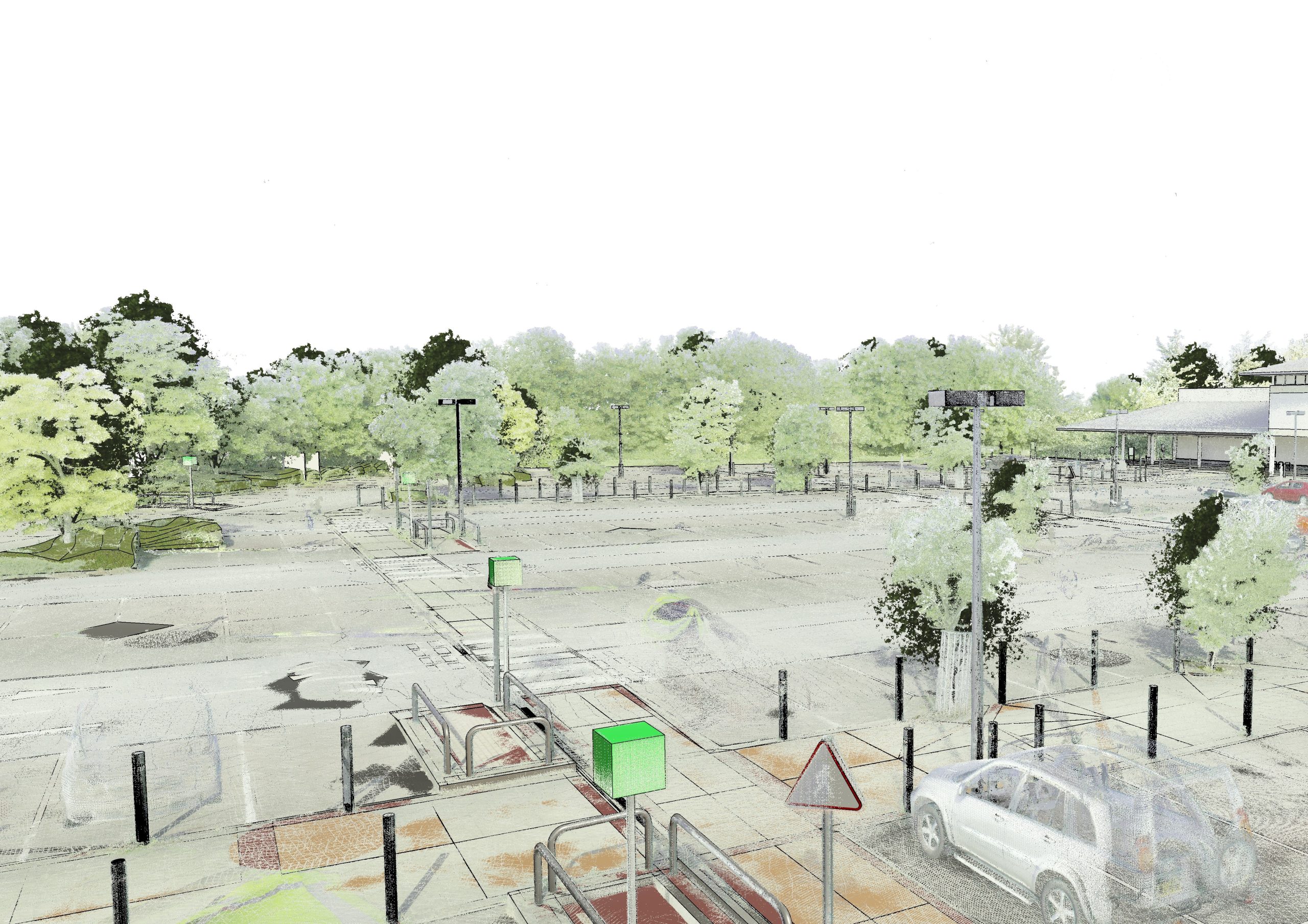

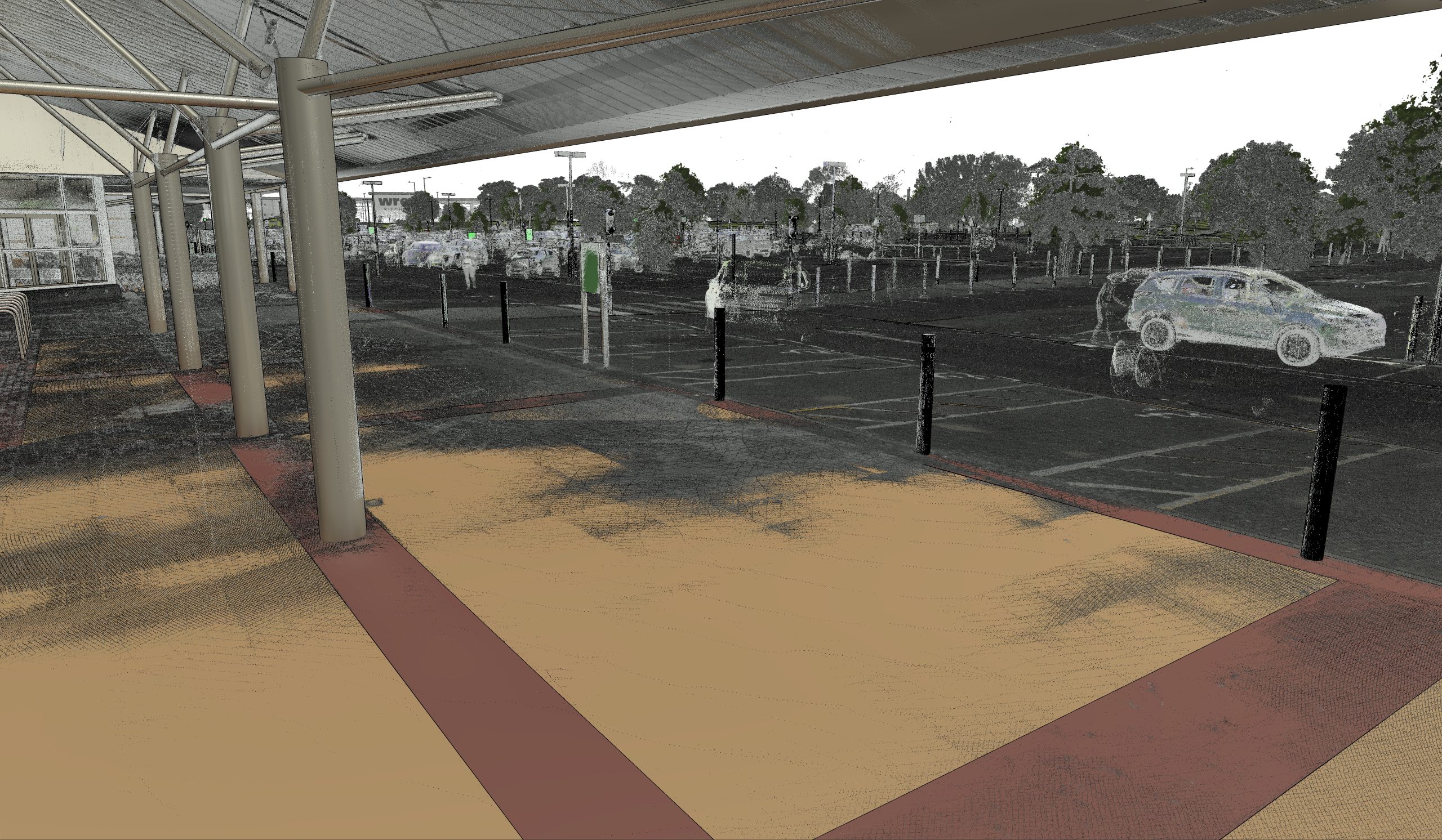

- Rigorous Quality Assurance and Deviation Analysis: We employed specialized software to perform a direct comparison between the BIM model and the source point cloud data. This deviation analysis allowed us to meticulously check the accuracy of every modeled object, ensuring all components were well within the project’s stringent ±25mm tolerance. To verify structural composition, we combined detailed cross-sections within the BIM model with dedicated component inspection software.

- Multi-Source Data Triangulation for Detail Accuracy: For features requiring specific visual information, such as directional arrows and road markings, we triangulated data from multiple sources. By combining the point cloud, TrueView imagery, and satellite maps, we accurately determined the precise color and placement of these elements. Similarly, to ensure correct material application, we cross-referenced information from client-provided photographs and Google Maps data, allowing for the precise identification and assignment of each material type used in the project.

Business Impact

- Creation of a Definitive As-Built Model: ViBIM’s Scan to BIM Services delivered a highly accurate and detailed 3D as-built model of the existing site conditions. This digital twin eliminates the inaccuracies and potential errors associated with traditional manual surveying methods, providing a single source of truth.

- Foundation for Future Development: The resulting model provides a crucial and reliable foundation for all subsequent project phases. Stakeholders can now proceed with confidence in renovation, repair, and asset management activities, knowing they are working from a precise representation of reality.

See how we master massive-scale projects with proprietary tools and precision. Our Revit BIM Outsourcing Services are your key to scaling capacity and ensuring success on any complex site.