Business Needs

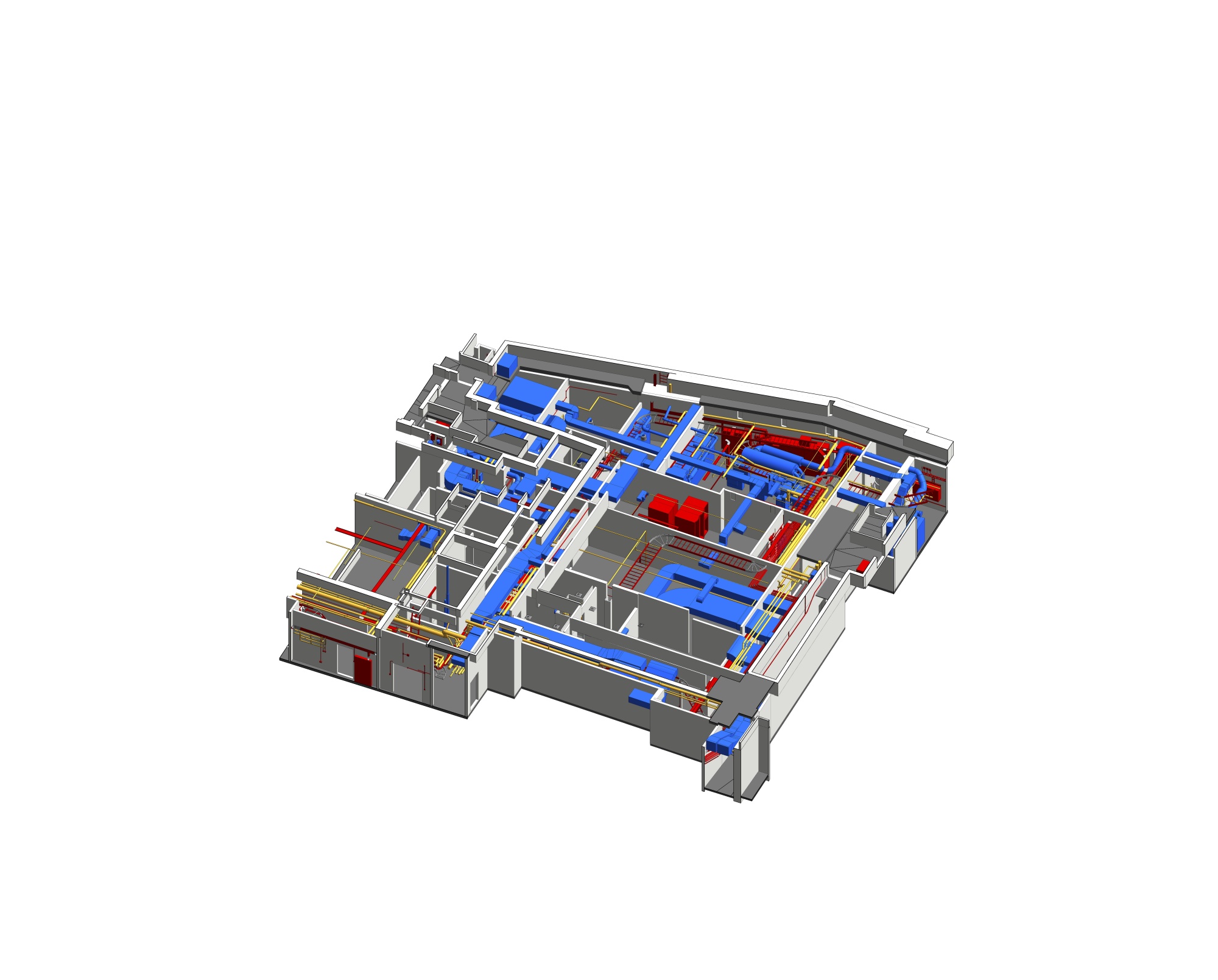

“498.UK” is a project to model an office building located in the UK, with a total area of approximately 13,000 m² distributed across one base level and five upper floors. The scope includes the exterior and partial interior of the main building, the surrounding topography, and the two facades of two adjacent buildings. The client specifically requires using the ‘Paint’ tool in Revit to precisely depict the actual surface materials of the buildings, ensuring model authenticity and accuracy.

Key Objectives

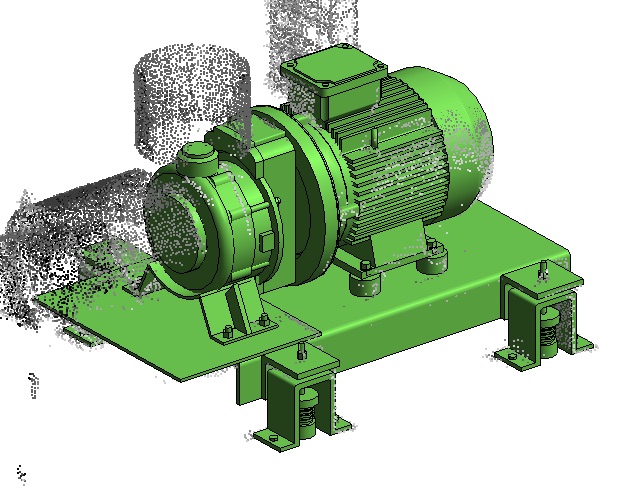

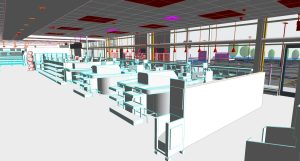

- Develop a 3D model derived from point cloud data to support the renovation process.

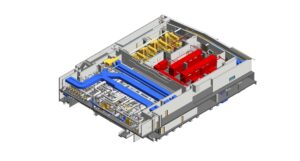

- Construct a comprehensive MEP (Mechanical, Electrical, Plumbing) model with an accuracy tolerance not exceeding ±15mm, adhering strictly to actual construction assemblies and technical specifications.

Challenges

Architecture (ARC):

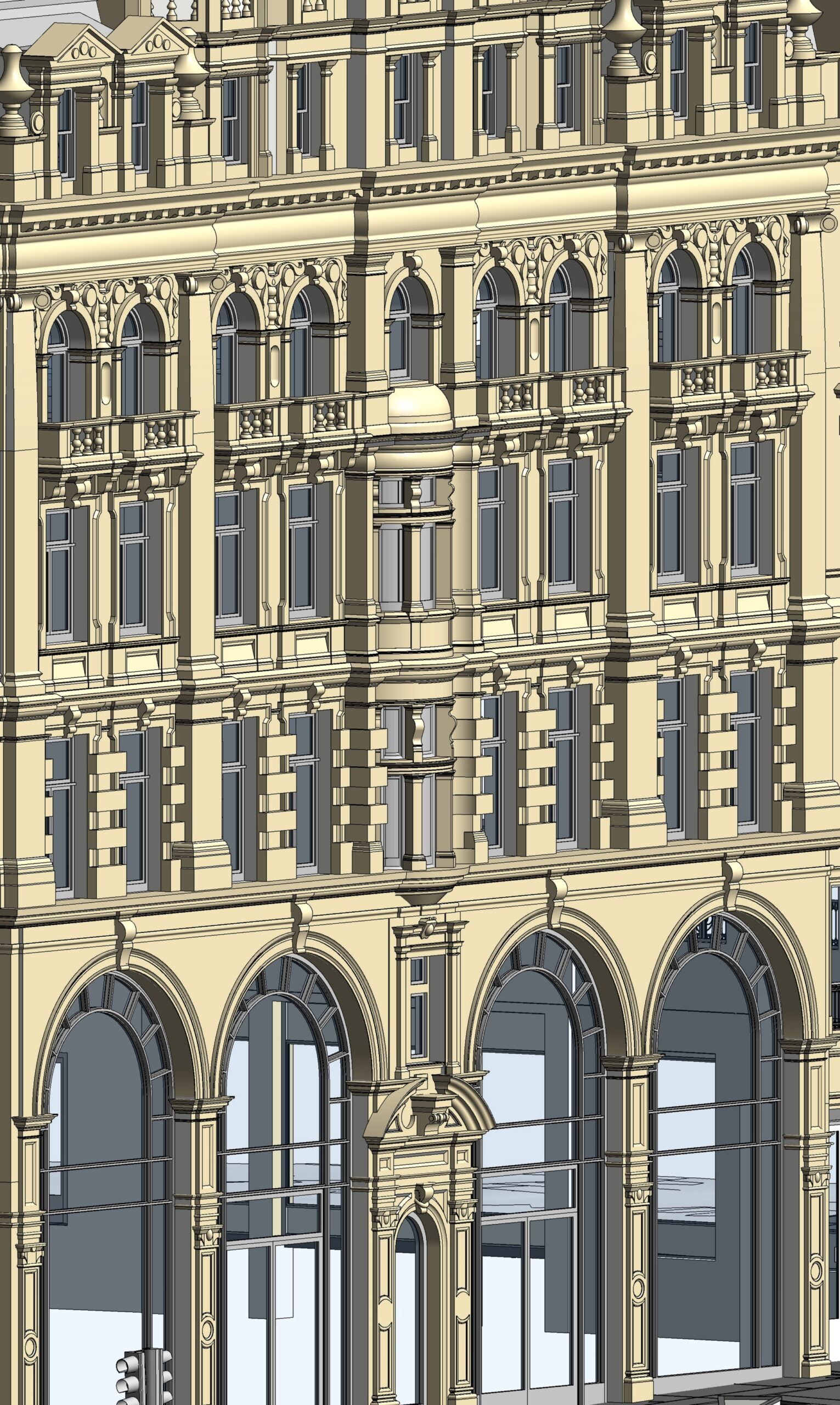

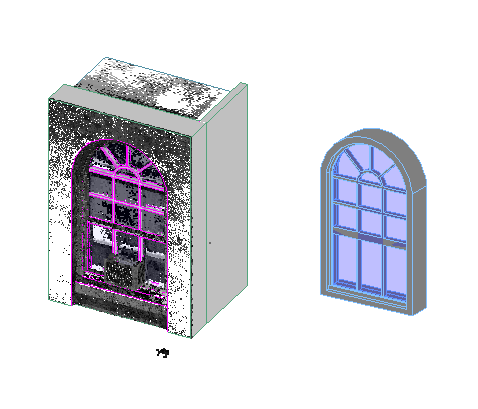

- The building’s exterior features intricate classical decorative elements, requiring high precision during modeling.

- To faithfully represent the existing conditions, maximum utilization of available data and information is necessary to accurately ‘paint’ the exterior surfaces, reflecting authentic materials, colors, and characteristics of the building.

MEP:

- Estimate: Estimating efforts was challenging due to limited input data for MEP disciplines. Available data only included PDF documents and exterior photographs, complicating the evaluation of interior spaces, access feasibility to false ceilings, density of MEP objects, number of technical shafts, and other critical information.

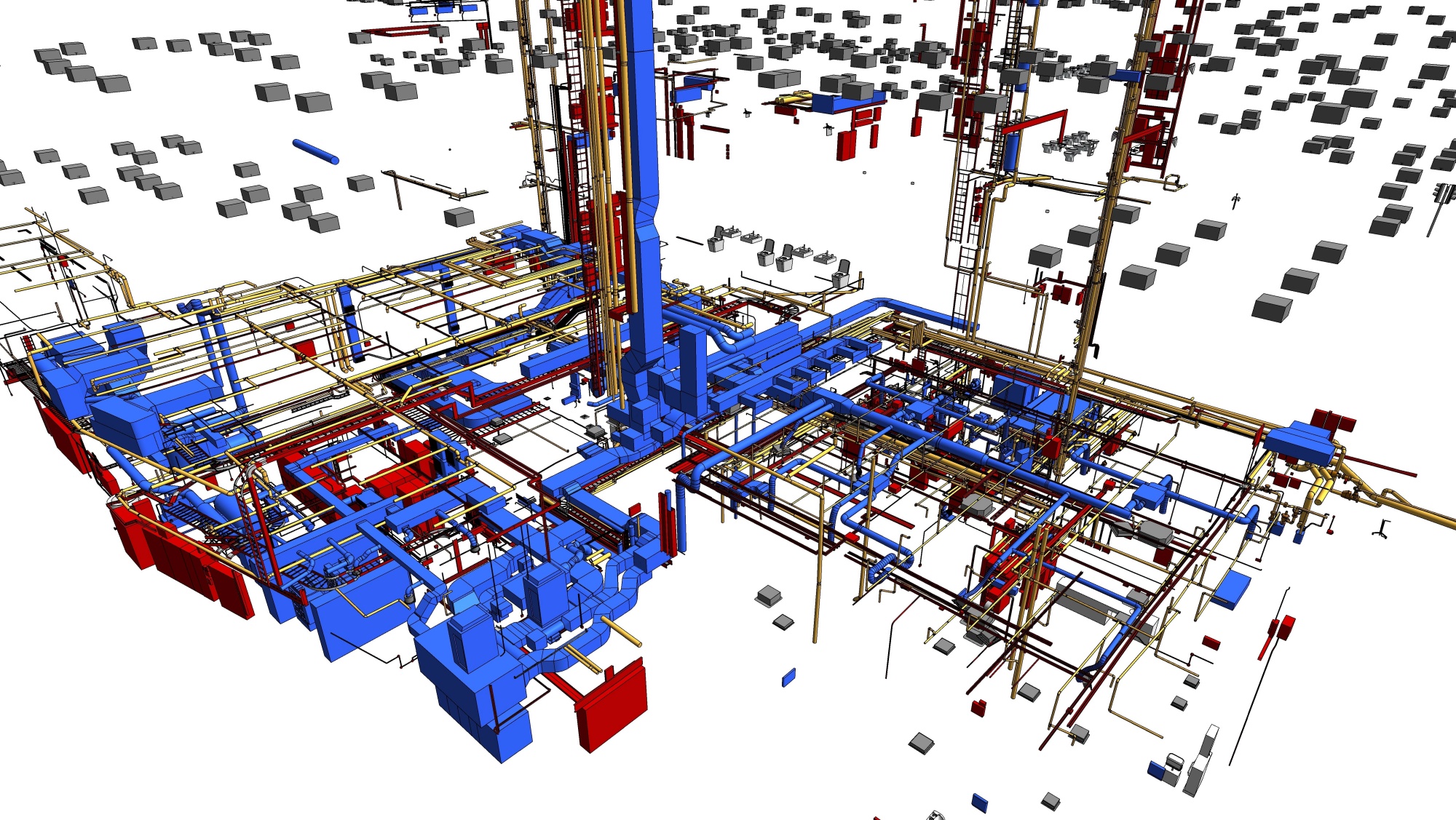

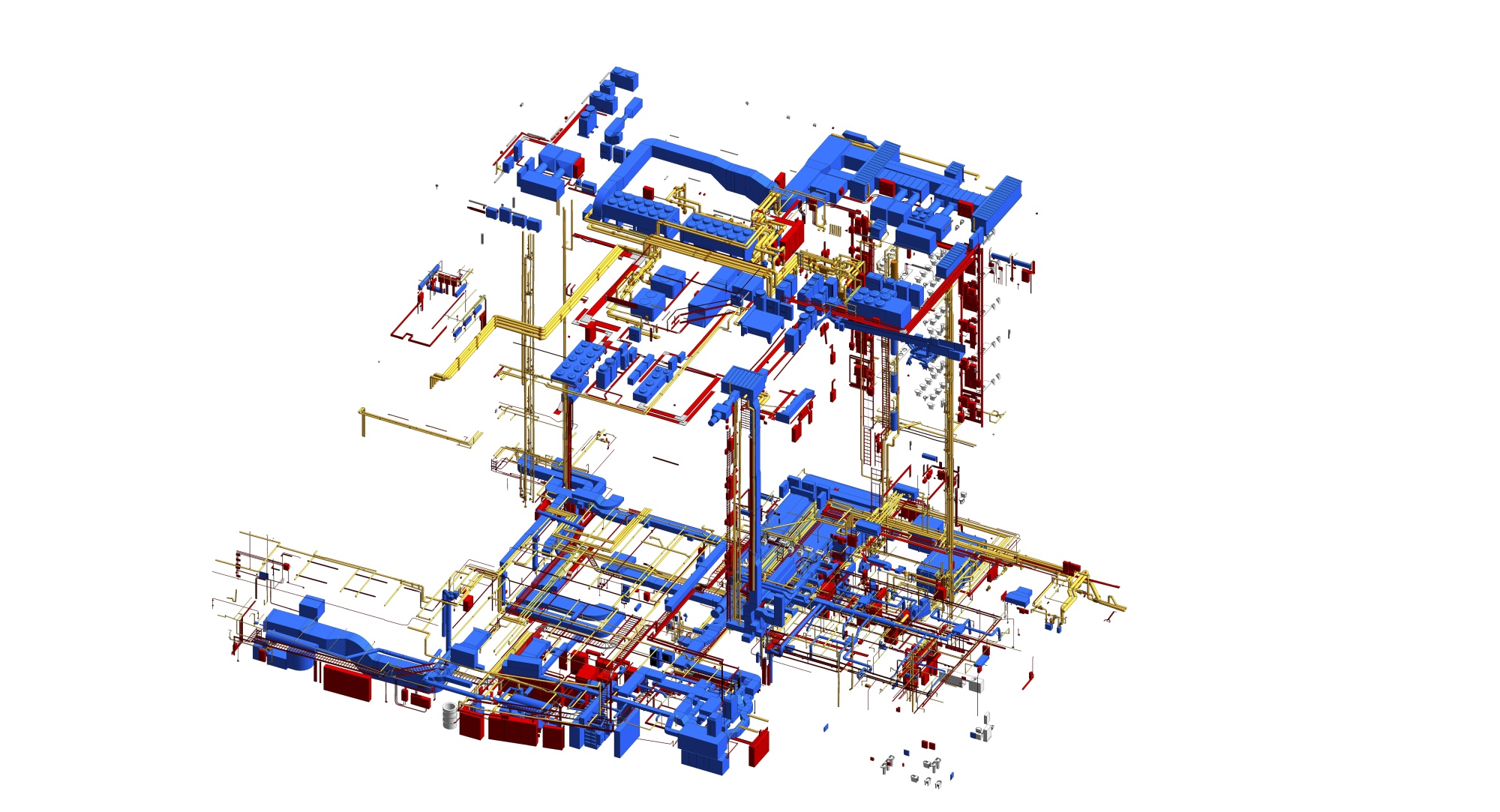

- MEP Modeling: A shortage of experienced personnel during project execution, with most team members being new hires lacking skills in point cloud interpretation, MEP drawing comprehension, Family optimization, or proper system parameter setting. This posed challenges in maintaining schedule and model quality. Dense MEP object distribution in basement, rooftop, and technical shafts, combined with poor-quality Point Cloud data exhibiting overlapping points and coordinate misalignments between the point cloud and the model, led to repeated adjustments and difficulty in accurate object identification. Nonetheless, the model had to be fully and precisely completed within a tight timeline to meet delivery deadlines.

- QA-QC: Efficient control over quantity and quality of MEP objects within the limited timeframe of QA-QC processes.

- Revised after QC: Ensuring thorough correction of all errors, including client-identified and latent defects, to guarantee optimal deliverable quality upon handover.

Project Risks:

- After reaching 80% project completion, the client identified errors in point cloud registration. To ensure quality, ViBIM had to research and implement corrective model adjustment solutions.

Our Solutions and Approach

Architecture (ARC):

- The modeling team conducted rigorous verification of architectural details by cross-referencing Point Cloud data, current condition photographs, and reference documents to ensure accurate reproduction of shape and classical ornamentation on the building façade.

- Surface material assignment was based on cross-referencing Google Maps, photos, TrueView, and existing data to ensure the model’s surfaces are ‘painted’ with accurate materials, colors, and realistic attributes per exterior zone.

MEP:

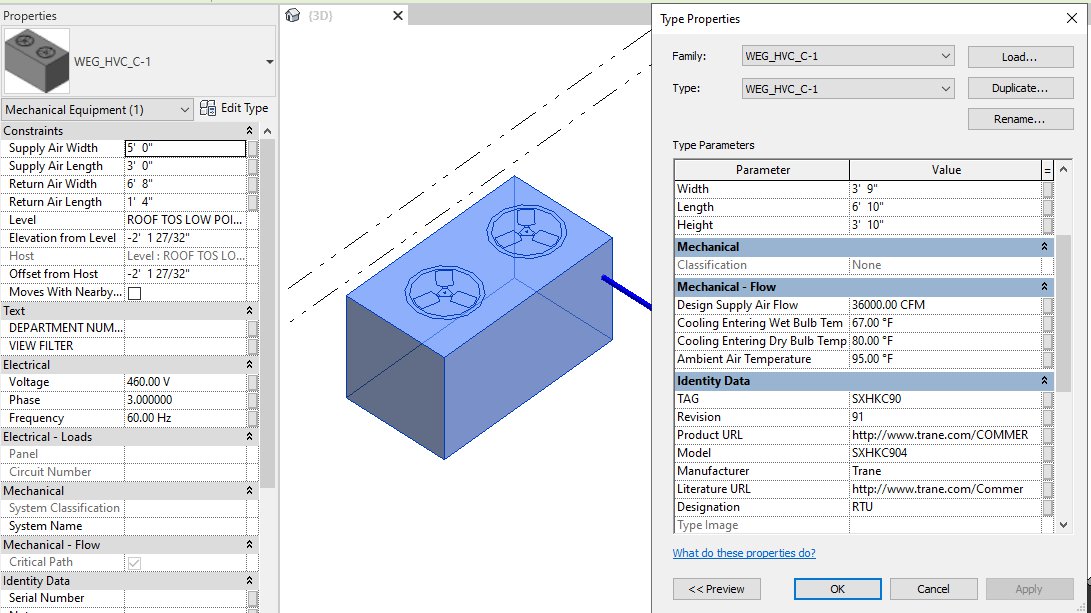

- Estimate: Hour estimation for each MEP system (HVAC, Electrical, Plumbing, etc.) was based on area, project type, and prior experience from similar projects. For instance, modern residential buildings tend to have denser MEP objects in basements and rooftop technical rooms compared to factories, where machinery and silos are concentrated.

- MEP Modeling: Staff were allocated by specific MEP systems and zones. Experienced personnel supervised new staff daily to ensure quantity and quality. Regular discussions clarified project-specific information and aligned methodologies between junior and senior team members. Active exchange of solutions was encouraged throughout implementation.

- To optimize modeling time, the project prioritized creating and using Parametric Families for MEP objects that had similar shapes and sizes.

- A dedicated MEP team was deployed to model the technical infrastructure by focusing on two key workstreams: modeling the separate vertical technical shafts, while concurrently modeling the HVAC and MEP systems along their horizontal routes. This approach was implemented to minimize omissions and discrepancies.

- Internal tools were deployed to accelerate modeling speed.

- Modeling was conducted simultaneously on Revit and Navisworks to minimize errors and potential deviations.

QA-QC:

- Multi-layer inspection processes were implemented, including section checks, Navisworks validation, and internal software-based verification to ensure MEP object quantity and quality. Internal tool utilization optimized efficiency and speed. Ambiguous objects were cross-checked against real images, TrueView, and Recap data provided by the client.

Point Cloud Error Resolution:

- Comparison with updated point clouds revealed significant deviations in elevation, tilt angle, and X-Y axis misalignment in completed work, posing a substantial challenge to quickly and accurately correct the model amidst tight deadlines. Adjusting elevation and tilt late in modeling risks system errors such as broken links, object disappearance, position shifts, and increased software processing time.

- To overcome this, ViBIM engaged senior QA management to thoroughly analyze root causes and propose optimal correction methods, while mobilizing additional qualified personnel to ensure schedule and quality adherence.

Business Impact

- The model accurately reflects the building’s existing conditions, especially classical architectural details and surface materials, providing clients with a comprehensive and visual understanding of the building’s current state.

- Using a detailed 3D model enables managers to efficiently plan maintenance, renovation, and upgrades.

- Precise information on MEP object locations and technical specifications facilitates easier and more effective management, maintenance, repair, and future system upgrades.

From intricate classical details to realistic material finishes, we capture every element with precision. Explore our 3D BIM Modeling Services to see how we deliver true-to-life digital assets for any project.