Business Needs

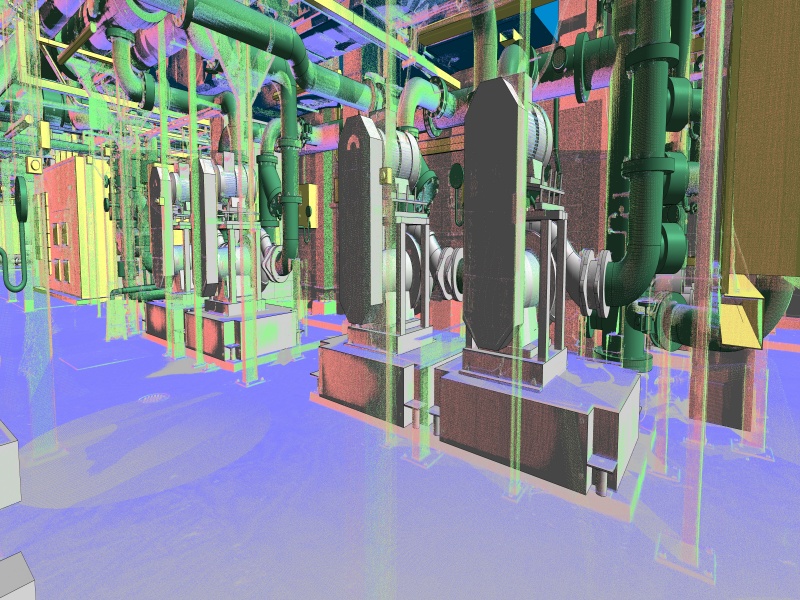

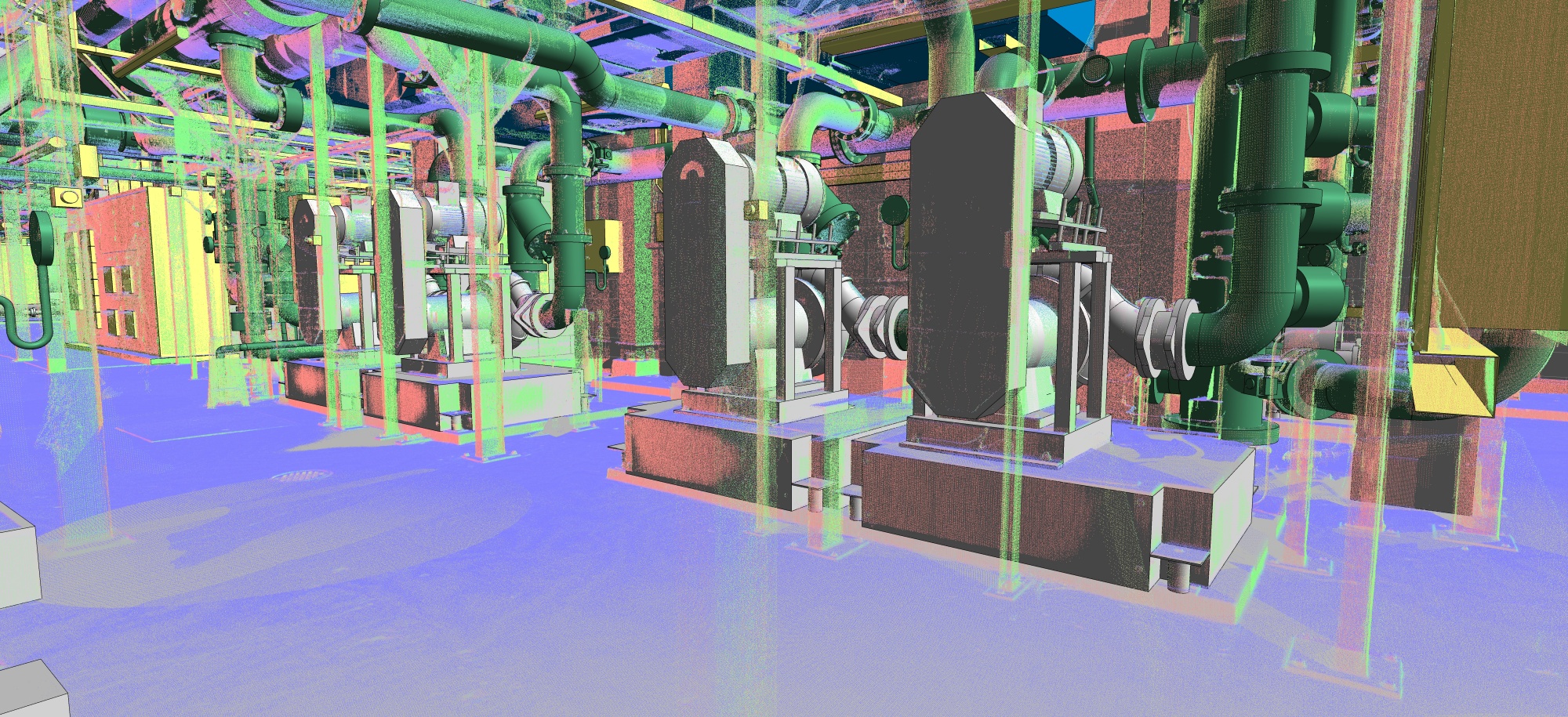

“600.UK” is an MEP system modeling project for an office building located in the UK, with an approximate modeled area of 4,700 m² and spanning four basement levels and thirteen upper floors. The scope is fully dedicated to modeling the entire building’s MEP systems, covering mechanical, piping, ducting, lighting, etc. Architectural and structural elements have been pre-provided to allow the team to focus on precise engineering model development to facilitate effective management and operation.

Key Objectives

- Estimate: Ensure project time estimates closely align with actual man-hours spent.

- MEP Modeling: Develop complete MEP models with dimensional accuracy within ±15mm, strictly adhering to actual construction details and technical specifications.

- QA-QC: Maintain high-quality standards throughout verification and adjustment phases to guarantee optimal deliverable quality before handover.

- Revised after QC: Confirm and ensure all issues identified during Quality Control (QC) have been thoroughly resolved.

Challenges

Estimate: Limited input data for MEP (only PDFs and exterior images) hindered accurate assessment of interior spaces, false ceilings, object density, and technical shafts, complicating precise estimation.

MEP Modeling:

- Significant processing time required for large and complex Point Cloud data.

- Poor quality Point Cloud data in basement levels made it difficult to accurately identify ventilation, plumbing, and cable tray systems.

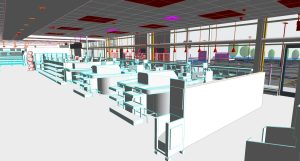

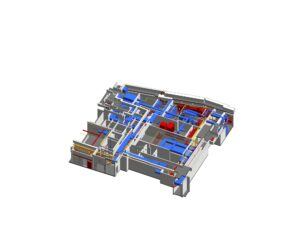

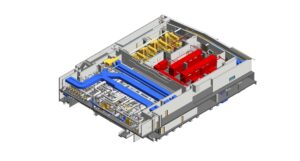

- Complex high-rise MEP systems, including HVAC, electrical, plumbing, fire protection, and dense piping and ductwork networks.

- Difficulty in extracting detailed information on existing MEP components (dimensions, materials, connections).

- Large rooftop machine rooms with oversized shafts connecting to basements through narrow technical ducts complicated high-quality Point Cloud data collection.

- Dense MEP object clusters in complex areas (basement, rooftop, shafts, corridors) combined with low-quality Point Cloud hindered full and accurate modeling within tight deadlines.

- Air terminals and distributed lighting fixtures across areas posed difficulties for equipment modeling.

QA-QC: Efficient control over quantity and quality of MEP objects within limited QA-QC timeframe was challenging.

Revised after QC: Ensuring thorough correction of all identified and latent errors to achieve optimal deliverable quality was a complex requirement.

Our Solutions and Approach

Estimate: To overcome limited input data, ViBIM applied benchmarking against similar past projects combined with detailed analysis of building-specific characteristics such as area, type, and MEP system density. Rich experience enabled accurate time estimation for each system (HVAC, Electrical, Plumbing, etc.) aligned with actual implementation.

Work division and strict supervision in modeling:

- Break down the project by individual systems, assigning distinct colors for each system.

- Enhance communication and clarify project information to ensure all team members adhere to standards and direction.

- ViBIM emphasizes continuous discussion and clarification of project-specific details throughout implementation. Regular exchanges ensure consistency in thinking and methodology between new and experienced staff, promoting teamwork and optimal solution finding.

Process optimization with smart tools and libraries:

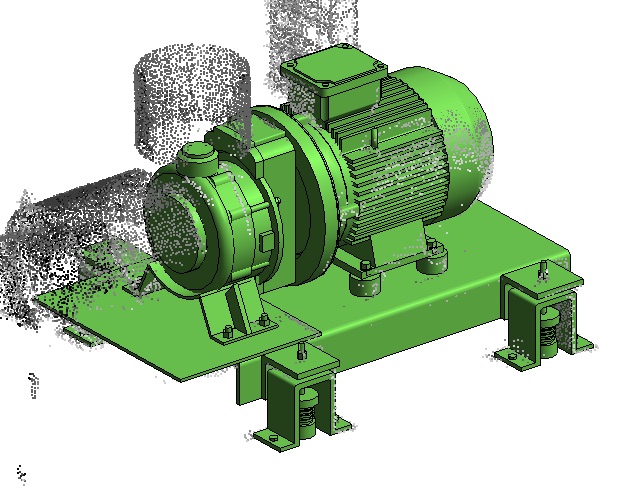

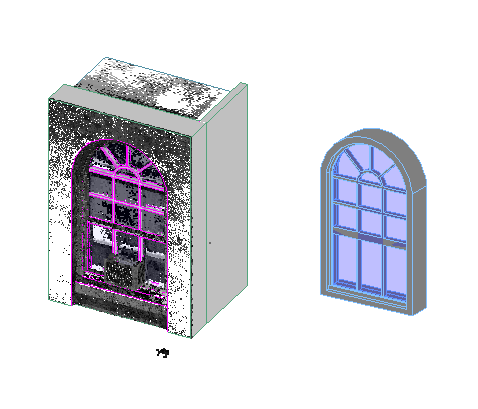

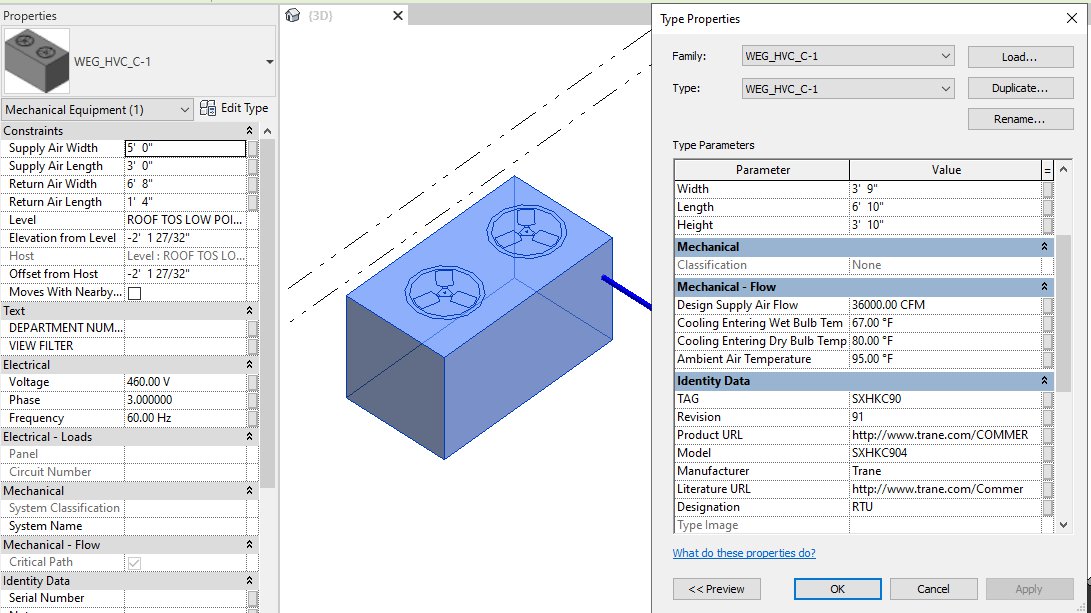

- To handle dense MEP objects and low-quality Point Cloud data, ViBIM’s expertise in Revit Point Cloud to BIM outsourcing allows for the creation of parametric Families for similar objects to reduce modeling time.

- Dedicated personnel focus on modeling shafts and linear systems using internal tools to accelerate modeling speed and integrate Navisworks Clash Detection within Revit, minimizing errors.

Multi-layer quality control with advanced technology:

- QA-QC: ViBIM implements a multi-tier review process, including sectional views, Navisworks inspection, and internal platform checks. Optimized use of internal tools enhances the speed and effectiveness of QA-QC.

- Revised after QC: To ensure optimal handover quality, ViBIM commits to thoroughly reviewing and correcting all client-identified errors, supplemented by a final internal quality check before product delivery, guaranteeing high-standard deliverables.

Business Impact

- Improved accuracy of cost and time estimation: Leveraging experience from similar projects and detailed analysis of building type, area, and MEP system density, ViBIM provides more accurate time and resource estimates. This enables investors and stakeholders to plan effectively, minimizing unexpected costs and delays.

- Enhanced quality and reliability of MEP models: Experienced teams closely monitor new personnel, ensuring dimensional tolerances within ±15mm and compliance with technical standards. Use of parametric Families and internal tools produces detailed, accurate models that reduce errors and potential clashes, guaranteeing deliverable quality.

- Optimized coordination and teamwork processes: ViBIM prioritizes project information clarity and methodology alignment. Close collaboration and use of Revit and Navisworks during modeling facilitate early issue detection, improve communication, and enhance interdepartmental collaboration, accelerating project timelines.

- Ensured highest quality of deliverables: Strict multi-layer QA-QC processes (sectional, Navisworks, internal tools) combined with support software enable ViBIM to detect and comprehensively correct errors before handover. This ensures the final model file meets project requirements and quality standards.

- Provision of visual and valuable information for later project stages: The detailed BIM model from ViBIM serves not only design and construction but also delivers long-term operational and maintenance value. Accurate data on MEP object locations and specifications facilitates easier management, maintenance, repair, and upgrades in the future.

See how we master the most dense and demanding MEP systems. Our Revit BIM Modeling Services deliver the clarity and precision required for any complex building.