Business Needs

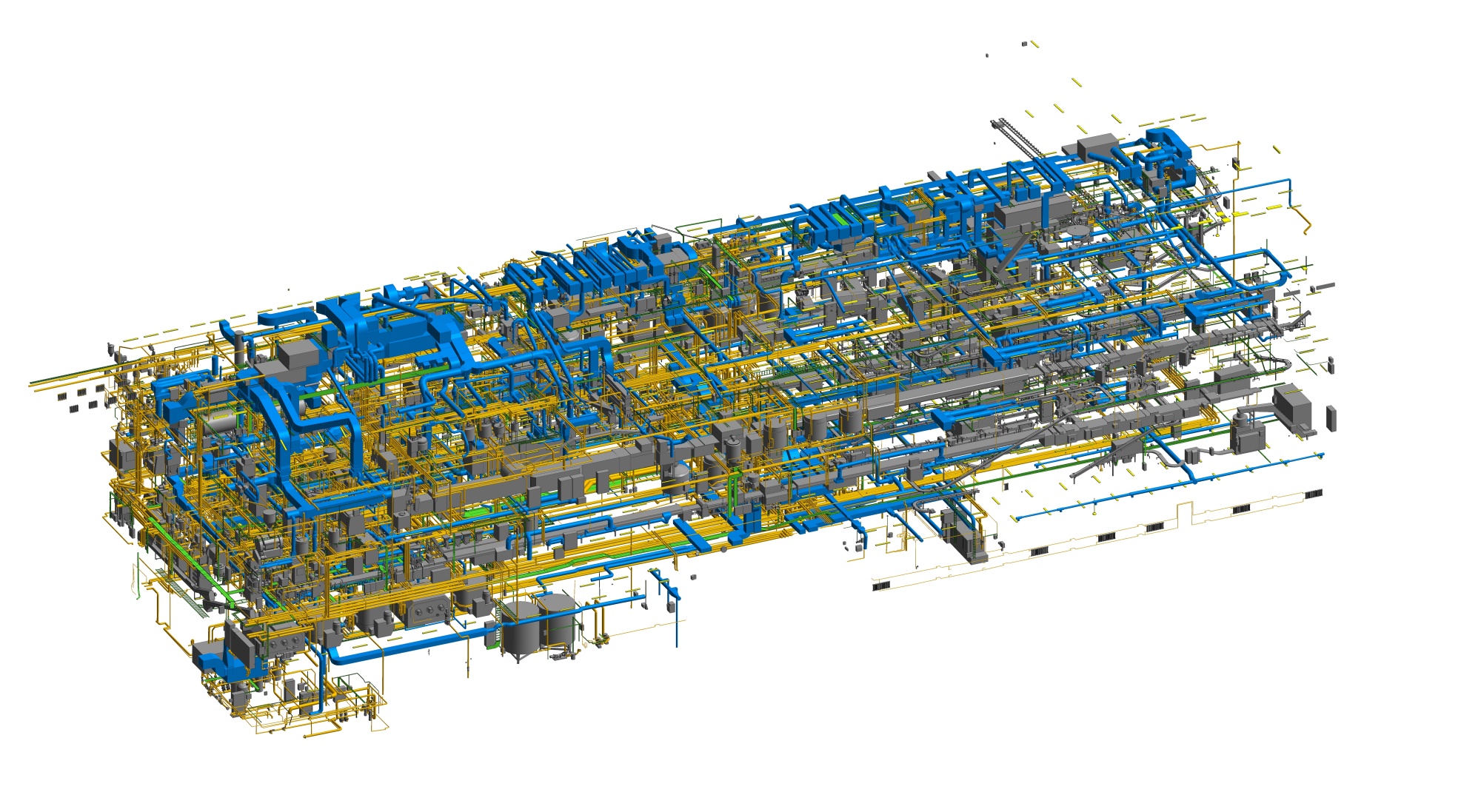

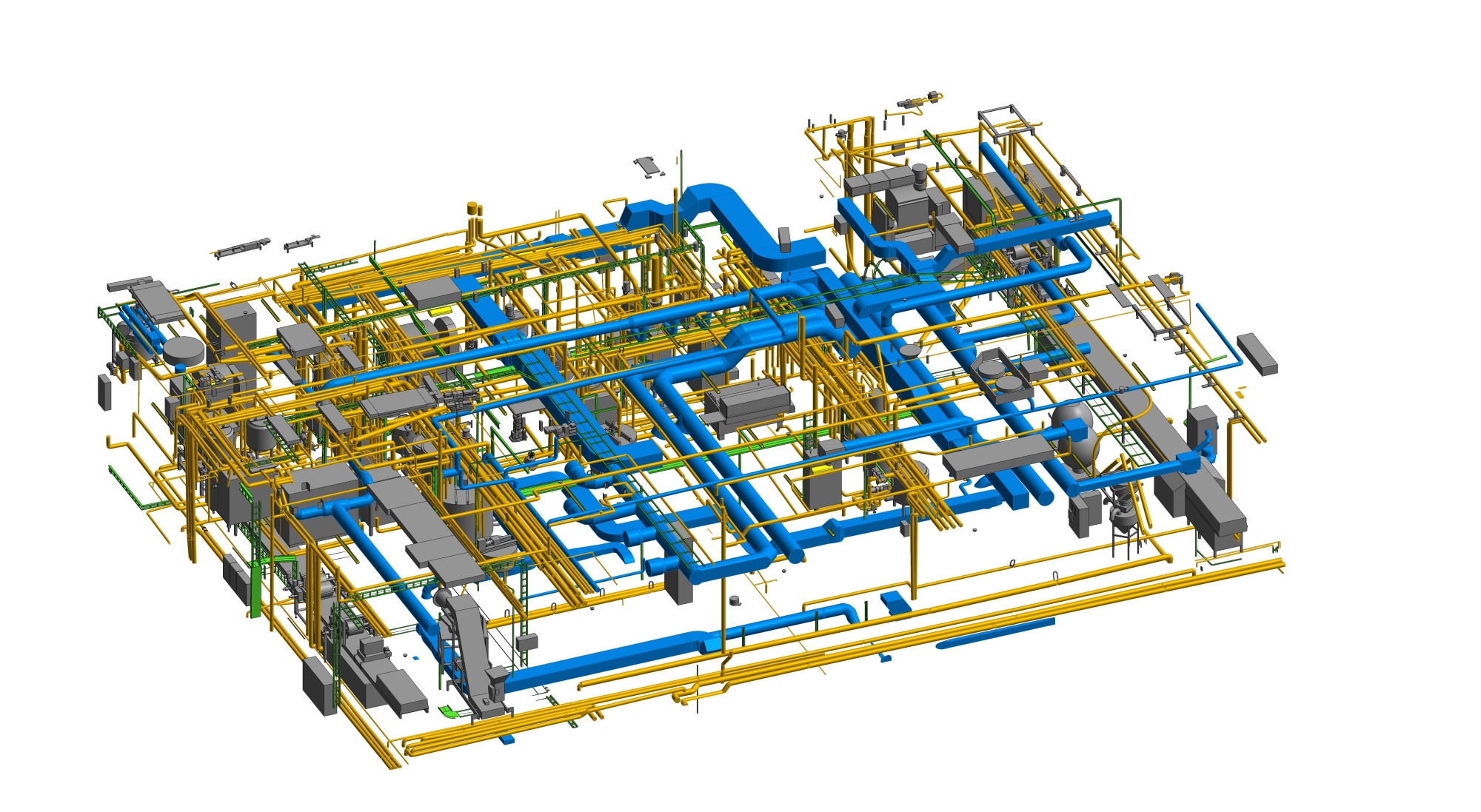

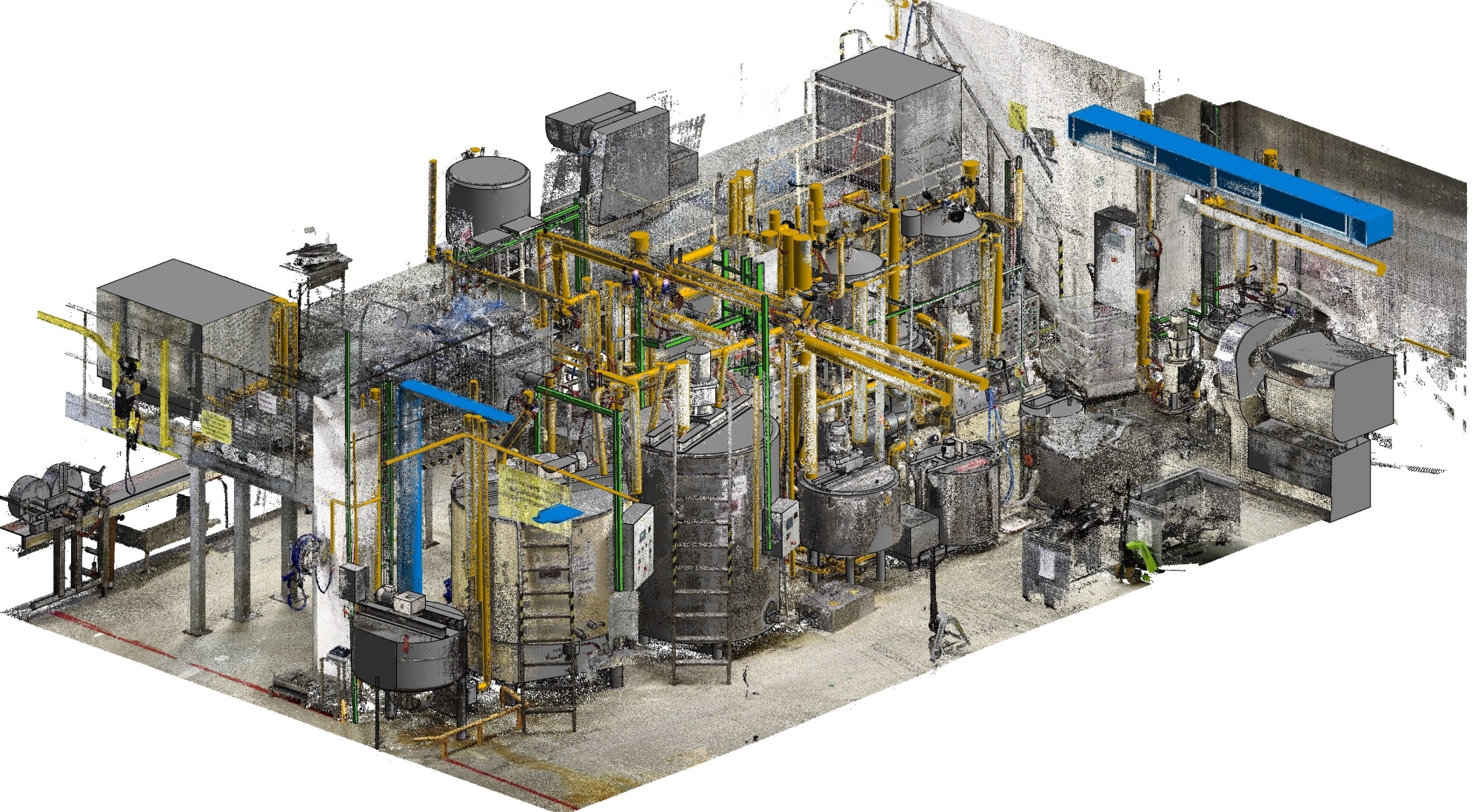

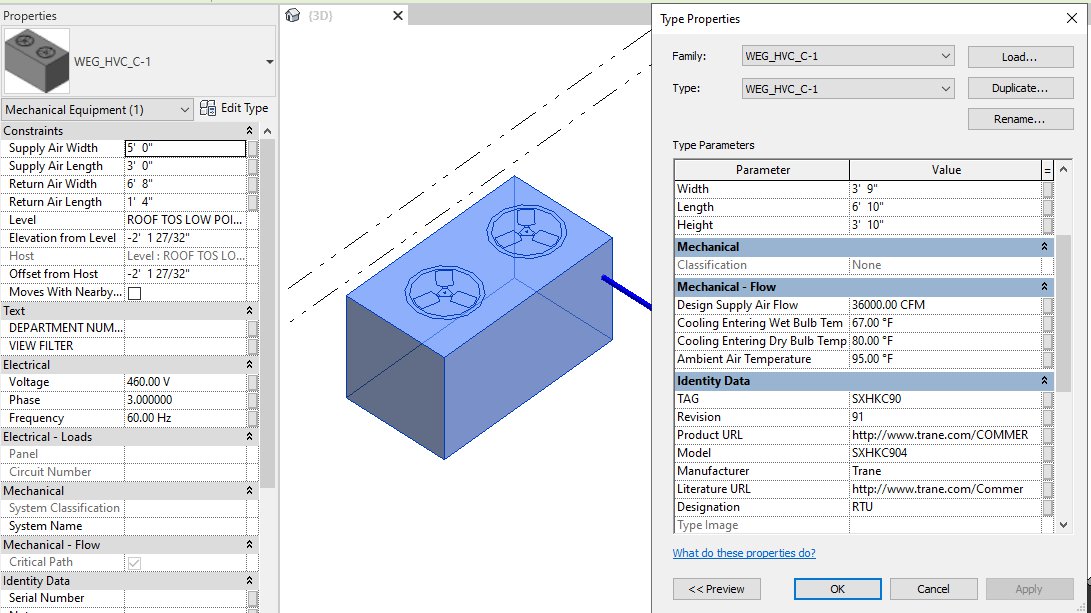

“486.US” is an MEP system modeling project for a factory situated in the United States, encompassing an area of about 3,800 m² and spanning one ground and five upper floors. The project scope is fully dedicated to the modeling of MEP systems, including mechanical, piping, and ductwork, distributed across all six levels of the plant. Architectural and structural models are intentionally excluded to optimize the management and enhancement of the facility’s current engineering systems.

Key Objectives

- Estimate: Achieve highly accurate project duration estimates that closely align with actual man-hours deployed.

- MEP Modeling: Perform comprehensive modeling of all MEP discipline objects, ensuring dimensional tolerance within ±15mm and strict compliance with real-world construction and technical specifications.

- QA-QC: Establish a rigorous Quality Assurance and Quality Control (QA-QC) process to maintain high quality throughout inspections and refinements, aiming for an optimal deliverable before client handover.

- Revised after QC: Confirm and resolve all defects identified during QC, producing a finalized model that accurately reflects the as-built status of the MEP systems.

- Value Added: Deliver a robust model serving as a foundational asset for future design, renovation, or facility management stages, while enhancing asset management efficiency and operational performance.

Challenges

- Estimate: Estimating was challenged by limited input data for MEP disciplines, relying only on PDFs and exterior images, which hindered assessment of interior space, object density, and technical shaft quantity.

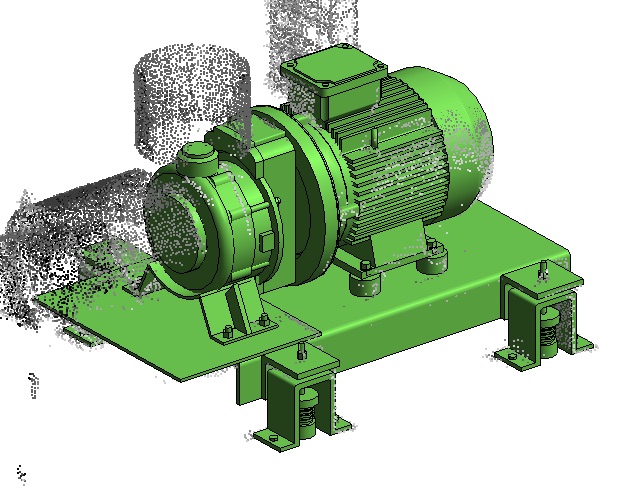

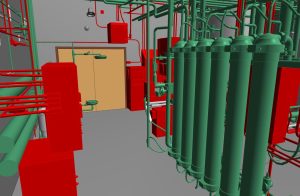

- MEP Modeling: Diverse and complex machinery shapes (e.g., conveyors, production equipment) complicated detailed and precise modeling. Dense piping networks required high accuracy and connectivity, complicating clear differentiation between pipe systems. High MEP object density in complex areas combined with limited Point Cloud data quality constrained recognition and precise modeling within a tight timeframe. Cable tray systems spread throughout technical shafts, electrical rooms, and machinery areas created additional difficulties in accurate modeling.

- QA-QC: Effective control of MEP object quantity and quality within limited QA-QC time demanded optimized workflows.

- Revised after QC: Ensuring thorough correction of all identified and potential errors to deliver an optimal quality product was a critical objective.

- General Challenges: The factory project scale and workload were extensive, imposing stringent requirements on management and execution. Numerous potential clashes between MEP systems and technical equipment required efficient coordination solutions.

Our Solutions and Approach

- Estimate: To ensure accuracy, ViBIM applied benchmarking methods using experience from similar projects and analyzed project-specific characteristics.

- MEP Modeling:

- Efficient volume management: The project was segmented by floor and area for better control.

- Complex object modeling: The team conducted discussions to develop optimal strategies for their Revit 3d BIM Modelling Services, building models by sub-assemblies and assembling them, utilizing Revit Modeling tools and consulting reference

- Connectivity and accuracy assurance: Used Revit’s “Show Disconnect” tool to verify system connectivity post-completion.

- Precise pipe system identification: Relied on experience, Point Cloud data, and examined endpoints and equipment connections.

- Prioritized modeling main components: Focused first on main pipes and risers, then secondary branches.

- Visualization for system control: Applied distinct material colors and filters to display each pipe system clearly.

- Enhanced communication and collaboration: Maintained continuous exchanges to ensure understanding of schematic diagrams and system connectivity.

- QA-QC: Conflict detection and resolution: Utilized Navisworks software for identifying and resolving potential clashes.

- Revised after QC: Post-QC, all errors were exhaustively corrected to guarantee the highest quality deliverable.

Business Impact

- The BIM model accurately reflects the as-built conditions, a key benefit of Point Cloud to BIM Service, facilitating effective maintenance and asset management.

- The comprehensive plant visualization enables clients to grasp the overall layout easily, optimizing operational workflows that 2D drawings cannot fully convey.

- Leveraging experience from similar projects and thorough analysis, ViBIM provides precise time and resource estimates supporting efficient planning, avoiding cost overruns and schedule delays.

- MEP Modeling was conducted by a professional team adhering to tolerance and technical standards, utilizing intelligent tools and libraries to ensure detailed, accurate models and minimize conflicts.

- ViBIM prioritizes clear communication, consensus on workflows, and the application of Revit and Navisworks, enhancing interdepartmental coordination and expediting project progress.

- A stringent QA-QC process with multiple review layers and supporting tools ensures all errors are detected and resolved before delivering an optimal-quality product.

- The detailed BIM model is not only beneficial for current stages but also serves as a precise and visual information source for subsequent operation, maintenance, repair, and upgrade phases, optimizing asset and facility management.