Scan to BIM for an Educational Facility in the UK

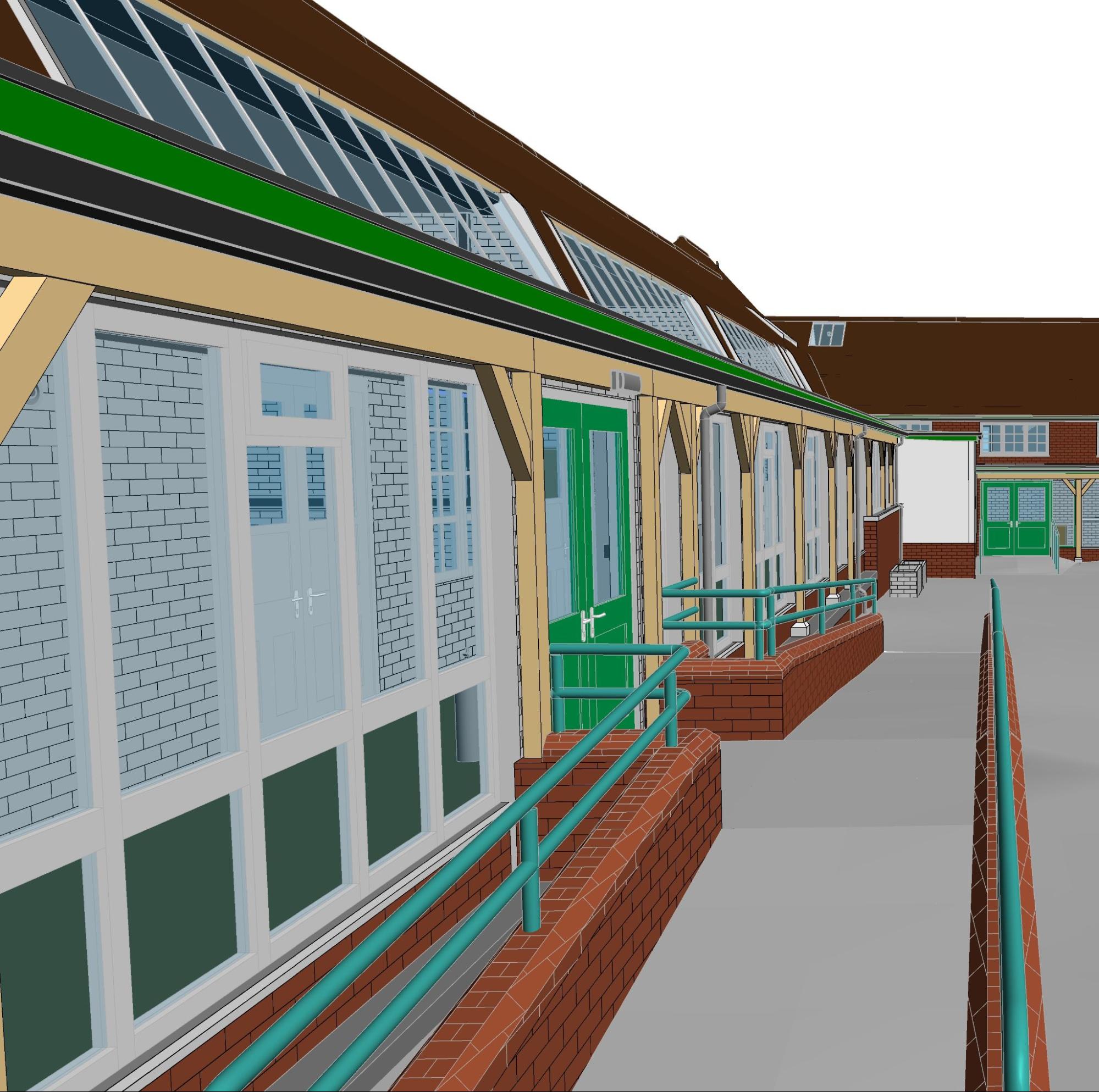

Project 678.UK was a comprehensive Revit Modeling initiative for a school in the United Kingdom, executed within a one-month timeframe from August to September 2024. The project covered a total area of 4,900m² across two floors. Our specialists were responsible for modeling the facility’s Architecture, Structure, and MEP (Mechanical, Electrical, and Plumbing) systems to a high Level of Development (LOD) 400. Utilizing Point Cloud data, images, and existing 2D drawings as inputs, the team successfully navigated a key project challenge: the client’s strict requirement for precise material application for every building element, ensuring the final Revit model was an accurate digital asset ready for construction.

| Client Profile | Confidential |

| Project Location | United Kingdom |

| Industry | Education |

| Total Area | 4900m2 |

| No of floors | 2 Floors |

| LOD | LOD400 |

| Inputs | Point Cloud, Image, 2D Drawings |

| Deliverables | Revit File |

| Software Used | Revit, Navisworks, internal tools |

Business Needs

This case study focuses on the “678.UK” project, a comprehensive educational facility located in the United Kingdom, spanning a significant area of 4,900 square meters across two floors. The scope of our work encompassed the detailed modeling of both the interior and exterior elements of the entire campus, which is composed of three distinct structures: a central main building flanked by two uniquely designed arc-shaped wing buildings. The client required accurately managing material information and component names, separating material types and creating accurate material types within the model.

Key Objectives

- To develop a highly detailed as-built 3D model of the architectural and structural components at a Level of Detail (LOD) of 400 for the extensive 4,900 m² school campus.

- To ensure meticulous management of all building information, with a specific focus on accurately naming components, defining and segregating material assets, and creating precise material types within the model.

Challenges

- Accurate Material Assignment: The project involved a vast array of different building elements and components across three separate buildings, necessitating the precise and correct assignment of materials to each specific object to accurately reflect the as-built conditions.

- Systematic Model Standardization: A primary challenge was the client’s emphasis on creating a systematically standardized model. The requirement was to prioritize the logical organization of the model—ensuring every object was classified under the correct Revit Category, assigned the appropriate family type, and applied with the exact material—even above maintaining the tightest geometric deviation (Tolerance) against the point cloud, to guarantee the model’s long-term informational value, interoperability, and usability for future project phases.

Our Solutions and Approach

- Multi-Faceted Material Verification: To guarantee absolute precision and consistency in material assignment, our team implemented a comprehensive, multi-dimensional verification methodology. This approach went beyond a single data source, integrating and meticulously cross-referencing information from the detailed point cloud data, high-resolution site photographs, and immersive TrueView imagery. By synthesizing these diverse inputs, we were able to gain a holistic and granular understanding of each surface’s texture, condition, and unique characteristics. This enabled our modelers to assign materials with the highest degree of accuracy, ensuring the final BIM model was a true replica that precisely reflected the real-world material types and their intrinsic properties.

- Adherence to Revit System Standards: A fundamental principle of ViBIM’s workflow is the consistent prioritization of Revit’s native system components. In the 678.UK project, we made full use of standard Families and Categories to achieve this. This strategic decision not only ensured that the model was constructed with structural and component accuracy but also that it adhered strictly to established BIM conventions and design logic. The critical advantage of this approach is its inherent reliability; it ensures that all elements, including any necessary custom components, are embedded with complete, accurate, and consistent material information, fostering a coherent and trustworthy BIM data ecosystem for the client.

Business Impact

- Creation of a Definitive As-Built Model: The primary business impact was the delivery of a comprehensive as-built model that serves as a reliable digital baseline. This model empowers the client to securely store and meticulously analyze the facility’s data, providing an invaluable resource for planning future renovations, upgrades, and maintenance cycles with confidence.

- Enhanced Data Extraction Capabilities: The systematic classification and precise material assignment within the model provided a significant advantage. The client is now able to easily and accurately extract detailed material information, schedules, and quantities for any component within the project, streamlining procurement, cost estimation, and asset management processes.