Revit Modeling for Supermarket in the United Kingdom

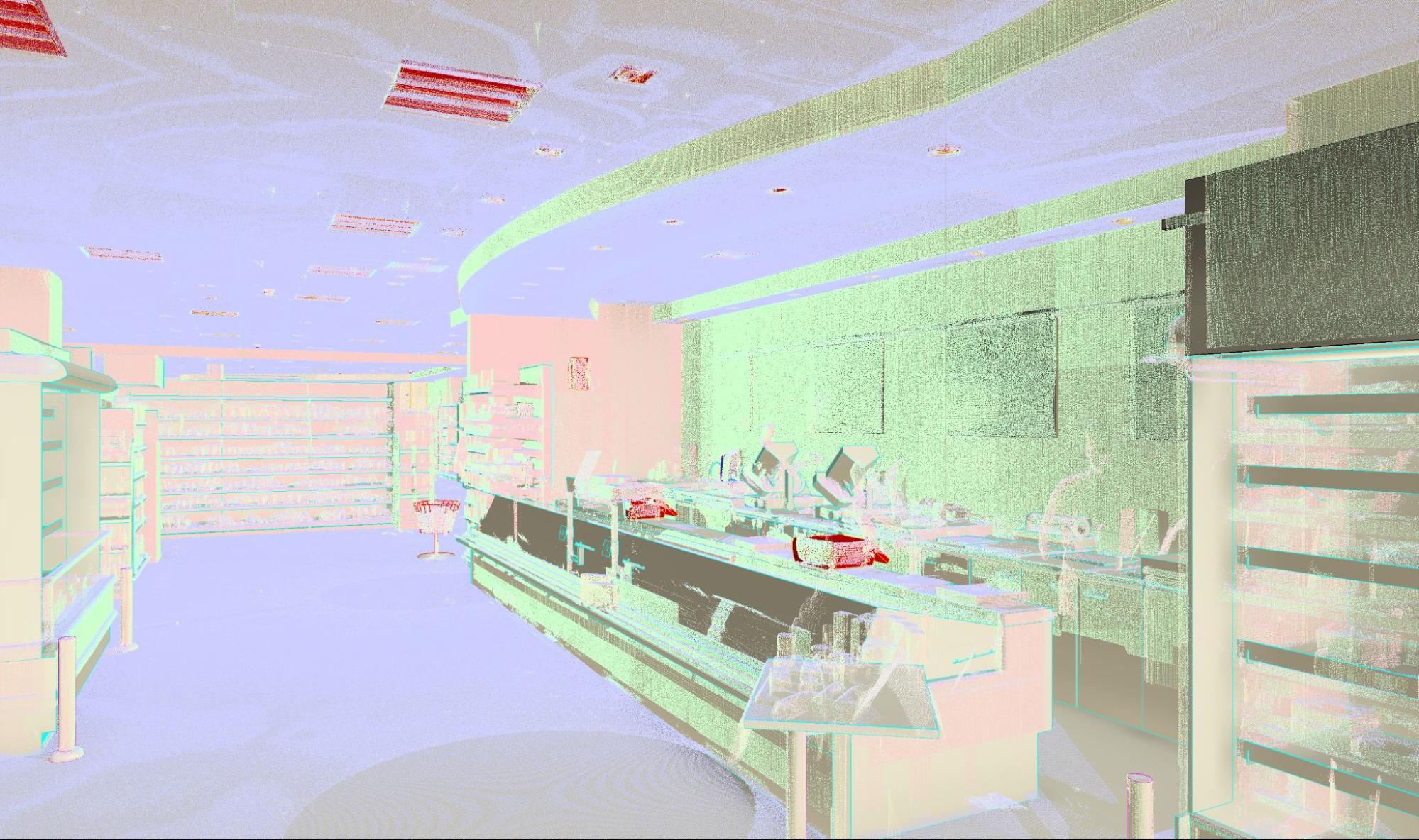

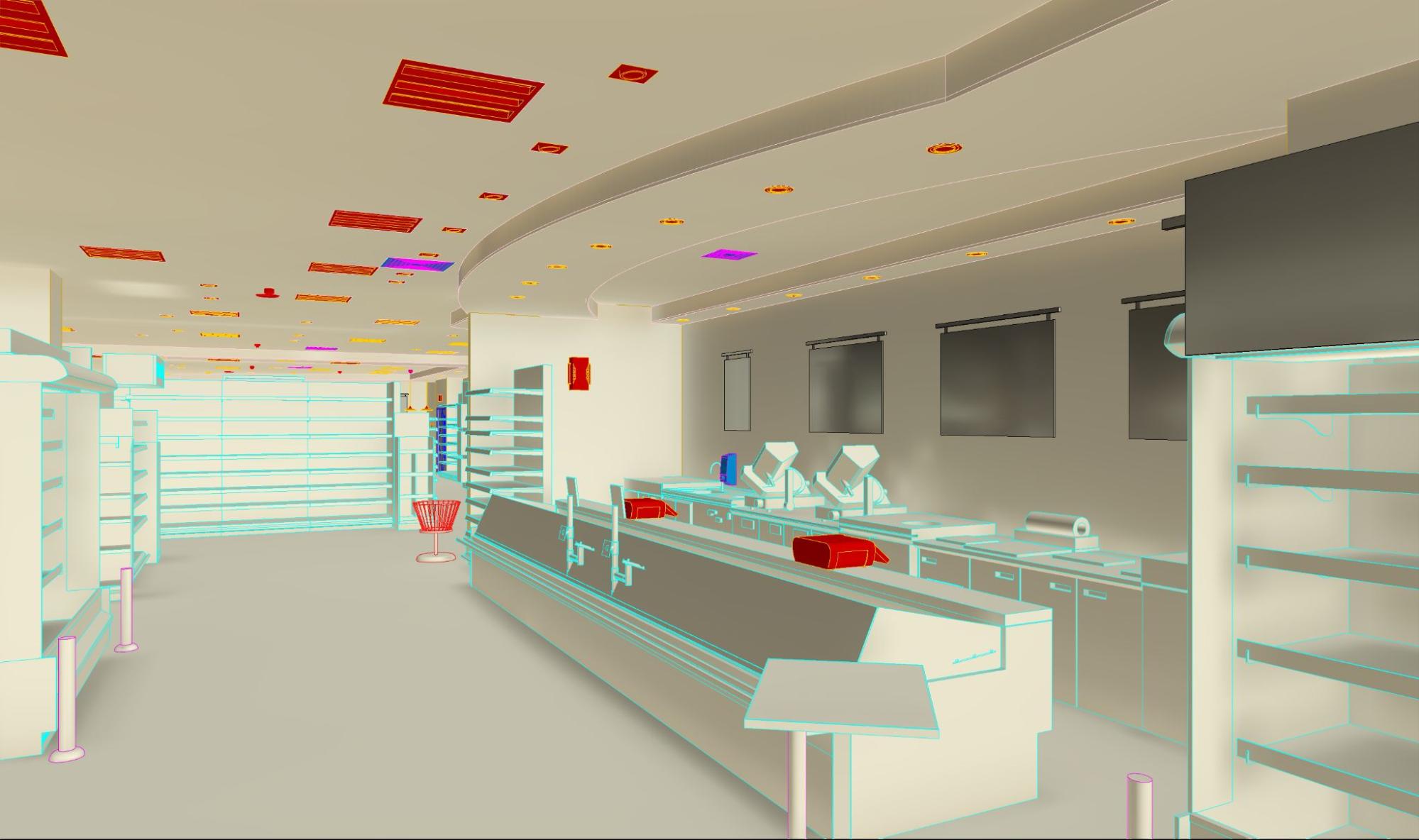

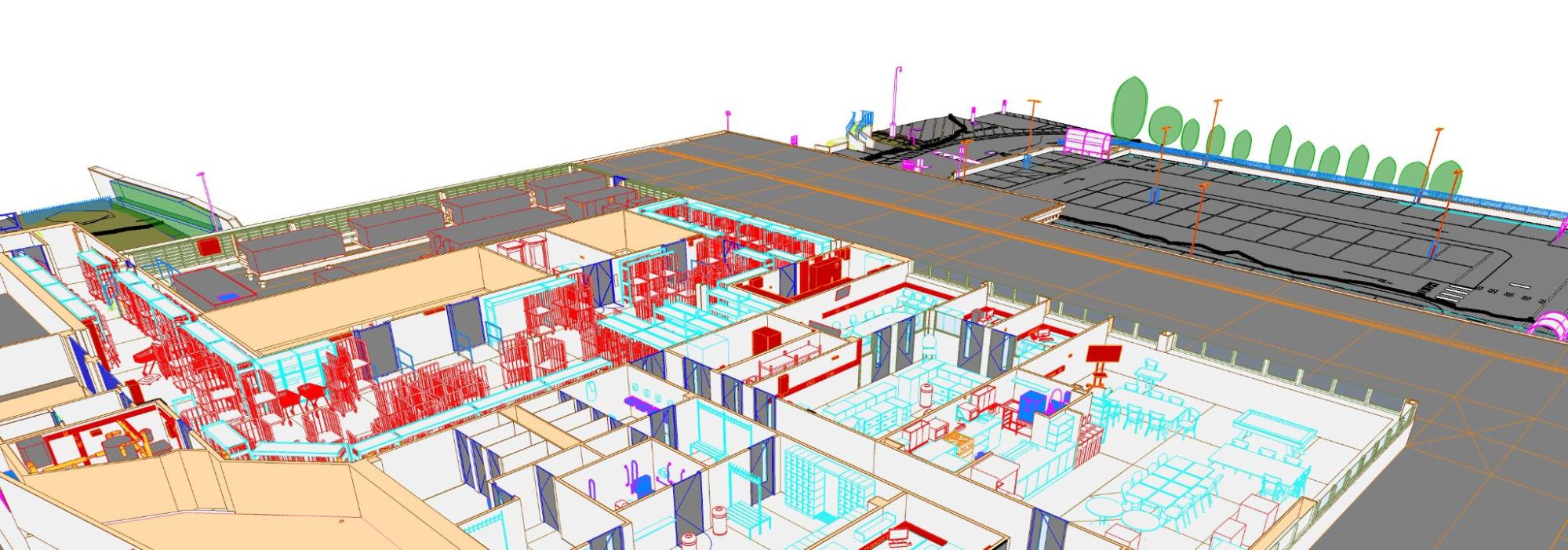

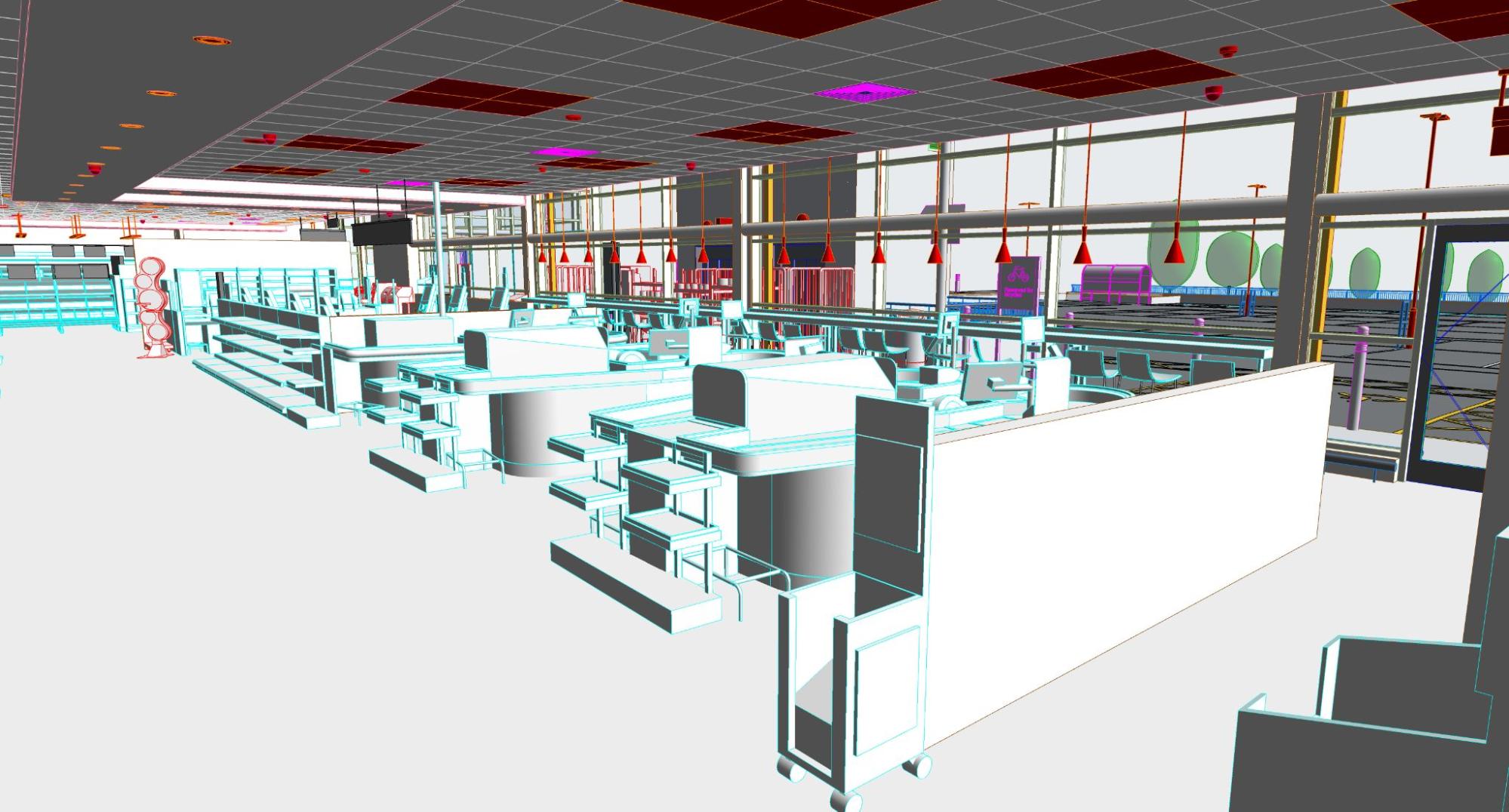

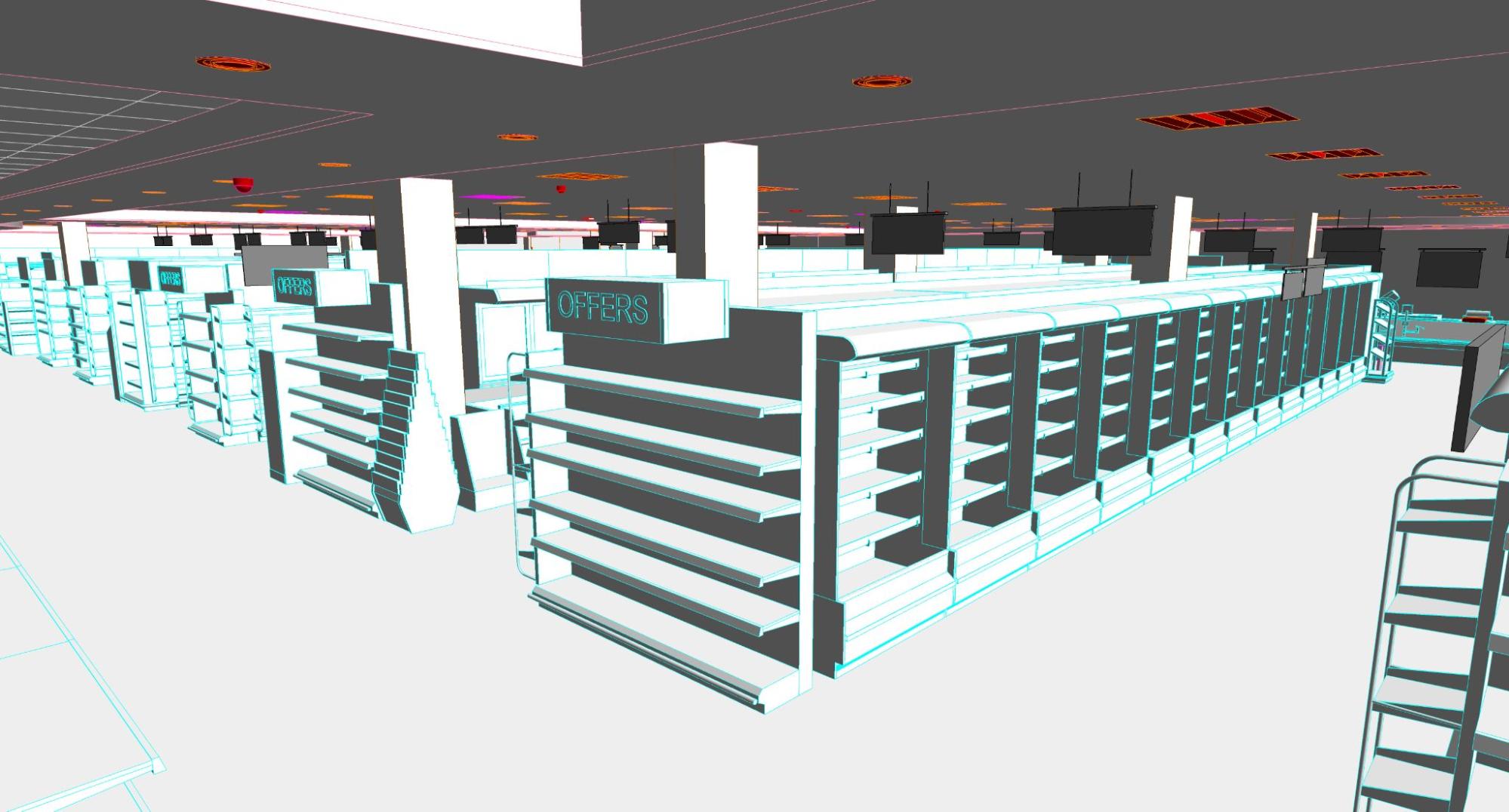

Project 635.UK involved the development of a comprehensive As-Built BIM model for a large-scale supermarket located in the United Kingdom, executed over a two-month period between April and June 2024. The facility spans a substantial area of 8,300m² distributed across three floors. The scope of work required the complete Revit Modeling of the project’s architecture, structure, topography, and MEP (Mechanical, Electrical, and Plumbing) systems. Leveraging high-density point cloud data and existing PDF documents as inputs, the team modeled the architectural, structural, and topographical elements to a highly detailed LOD 400, while the MEP systems were delivered at LOD 200. A key aspect of this project was successfully managing the large physical area while ensuring exceptional precision and detail in the final model, providing a robust digital asset for future facility management and renovation planning.

| Client Profile | Confidential |

| Project Location | United Kingdom |

| Industry | Supermarket / Retail |

| Total Area | 8,300m2 |

| No of floors | 3 Floors |

| LOD | LOD 400 (Architecture, Structure, Topography) LOD 200 (MEP) |

| Inputs | Point Cloud, PDF |

| Deliverables | Revit File |

| Software Used | Revit, Navisworks, internal tools |

Business Needs

The project, designated “635.UK,” involved an expansive three-floor supermarket facility located in the UK, covering an area of approximately 8,300 square meters. The primary business need was to create a comprehensive and surgically precise digital twin of the existing structure. This required a complete as-built model that integrated all Architectural, Structural, and Mechanical, Electrical, and Plumbing (MEP) disciplines. The resulting model needed to serve as the single source of truth for all future renovation, spatial planning, and facility management activities, demanding an exceptionally high level of accuracy and detail to support informed decision-making throughout the building’s lifecycle.

Key Objectives

The client outlined several critical objectives that would define the project’s success:

- To develop a highly accurate LOD 400 as-built 3D Revit model of the entire supermarket facility.

- To model all Architectural, Structural, and MEP disciplines with a strict accuracy tolerance not exceeding ±15mm when compared to the source point cloud data.

- To ensure the BIM model precisely reflected the true as-built conditions, including the exact construction, dimensions, and technical specifications of every piece of equipment, pipe, fitting, and their intricate connections.

- To accurately differentiate and map the various materials used for building components, particularly for different floor finishes and the external topography.

Challenges

Delivering a model of this complexity and scale presented a series of technical and logistical challenges. How does a team navigate such hurdles while maintaining the highest standards of quality and efficiency?

- Ambiguity of As-Is Conditions: The initial information provided for the MEP systems was severely limited, often consisting only of outdated PDF drawings or basic exterior photographs. This created significant difficulty in accurately assessing the interior spaces, understanding the structure above false ceilings, and anticipating the density of MEP components, making reliable time and cost estimates a formidable task.

- Complex Spatial Assessment: Supermarkets are vast environments where MEP systems are densely packed and frequently concealed by architectural finishes or operational equipment. This complexity made it challenging to visualize the complete system network and accurately estimate the full scope of the modeling work required from the outset.

- Custom BIM Family Refinement: As this project was part of a larger portfolio for the retail chain, all BIM families had to be client-provided to ensure standardization. This demanded a significant investment of time from our modeling team to meticulously study and adjust family parameters—including dimensions, geometry, and connectors—to ensure they perfectly mirrored the shape, size, and uniformity of the real-world objects captured in the scan data.

- Massive and Fragmented Point Cloud Data: The raw point cloud data was exceptionally large and delivered in numerous separate scans. The process of processing, registering, and cleaning this voluminous dataset was both time-consuming and resource-intensive, posing a potential bottleneck to the project timeline.

- Toposolid Implementation: This was our team’s inaugural project utilizing Revit’s new Toposolid feature. As a result, we encountered initial workflow challenges in implementing it efficiently across the extensive site topography.

- Complex Workset Management: With a collaborative team, the meticulous division of model elements into designated Worksets (e.g., Architectural Shell, External Areas, MEP) was critical. Any errors in assigning objects to the correct Workset could disrupt the collaborative workflow and compromise model integrity.

- High Volume Under Tight Deadlines: Effectively managing the quality assurance and control (QA/QC) for thousands of individual MEP objects within a compressed timeline was a significant undertaking, requiring a robust and efficient verification process.

Our Solutions and Approach

ViBIM addressed the project’s challenges by implementing a strategic, technology-driven approach grounded in process optimization and rigorous quality control. Here is how we successfully navigated these complexities:

- We meticulously defined the appropriate Worksets for all elements and enforced a clear protocol for assigning them. This ensures that every object is correctly categorized for collaborative workflows. Before each milestone delivery and final handover, we performed an audit using Revit filters to confirm no objects were assigned to the wrong Workset, thus guaranteeing model integrity.

- To ensure all elements adhered to the strict accuracy tolerance, we utilized an in-house tool to continuously monitor the deviation between the Revit model and the point cloud. This automated QA process ensured all components remained within the acceptable tolerance.

- Intelligent BIM Family Classification and Adaptation: We began by thoroughly analyzing the client’s BIM families against the point cloud data. We then meticulously classified these families by system (HVAC, Plumbing, Electrical, Fire Protection) and component type (valves, pipes, FCUs, electrical panels, air conditioners). This systematic classification helped prevent redundant modifications and ensured consistency across the model.

- We used section views in Revit and created federated models in Navisworks for comprehensive checks to validate the model’s structural integrity. We paid special attention to high-risk areas like stairwells and the interfaces between different worksets to proactively detect and resolve clashes.

- We combined multiple data sources: point cloud data, TrueView and Google Map to accurately delineate material boundaries.

- We optimized the workflow by using a tool to create a TopoSurface from the point cloud to manage the massive number of points effectively. Instead of handling a single, unwieldy surface, we divided the toposurface into smaller, manageable sections. We processed each section individually and then meticulously stitched the edges together to form a seamless final surface without gaps or steps.

Business Impact

By transforming complex point cloud data into an intelligent, data-rich BIM model, ViBIM provided significant, long-term value to the client, directly impacting their operational efficiency and future planning capabilities.

- Foundation for Future Renovations: The high-fidelity 3D model now serves as the definitive digital asset for the facility. It provides an invaluable database for all future renovation, upgrade, or expansion projects, offering a clear visual understanding of interior spaces, ceiling voids, and dense service runs, thereby empowering engineers to optimize new designs and mitigate the risk of on-site clashes.

- Enhanced Facility Management and Asset Tracking: The as-built BIM model grants the facility management team immediate access to detailed information for every MEP asset. This capability streamlines inventory management, simplifies the planning of preventive maintenance and component replacement schedules, and ultimately helps optimize the entire lifecycle and operational cost of the building’s assets.