Revit Modeling for Factory in the US

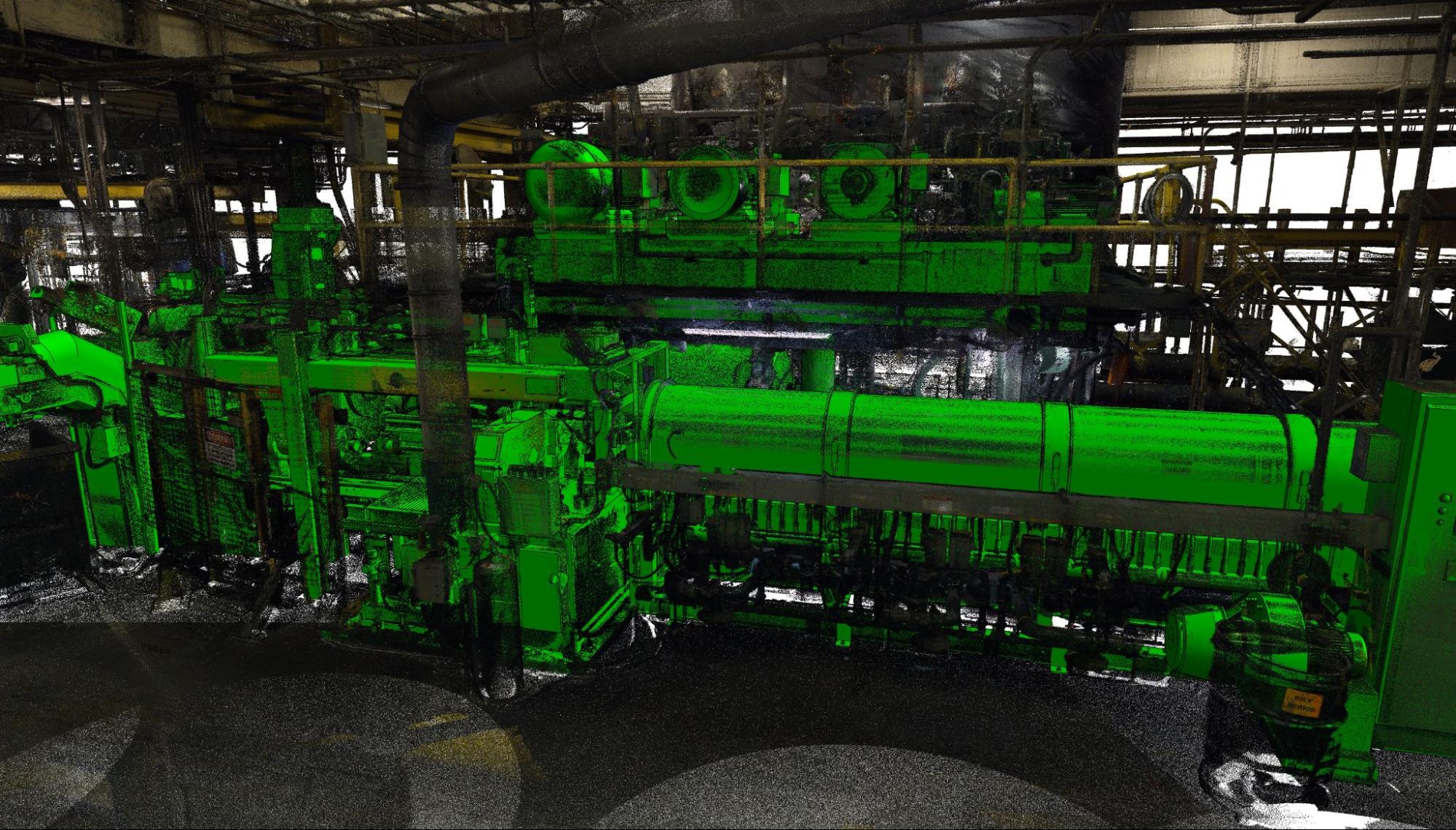

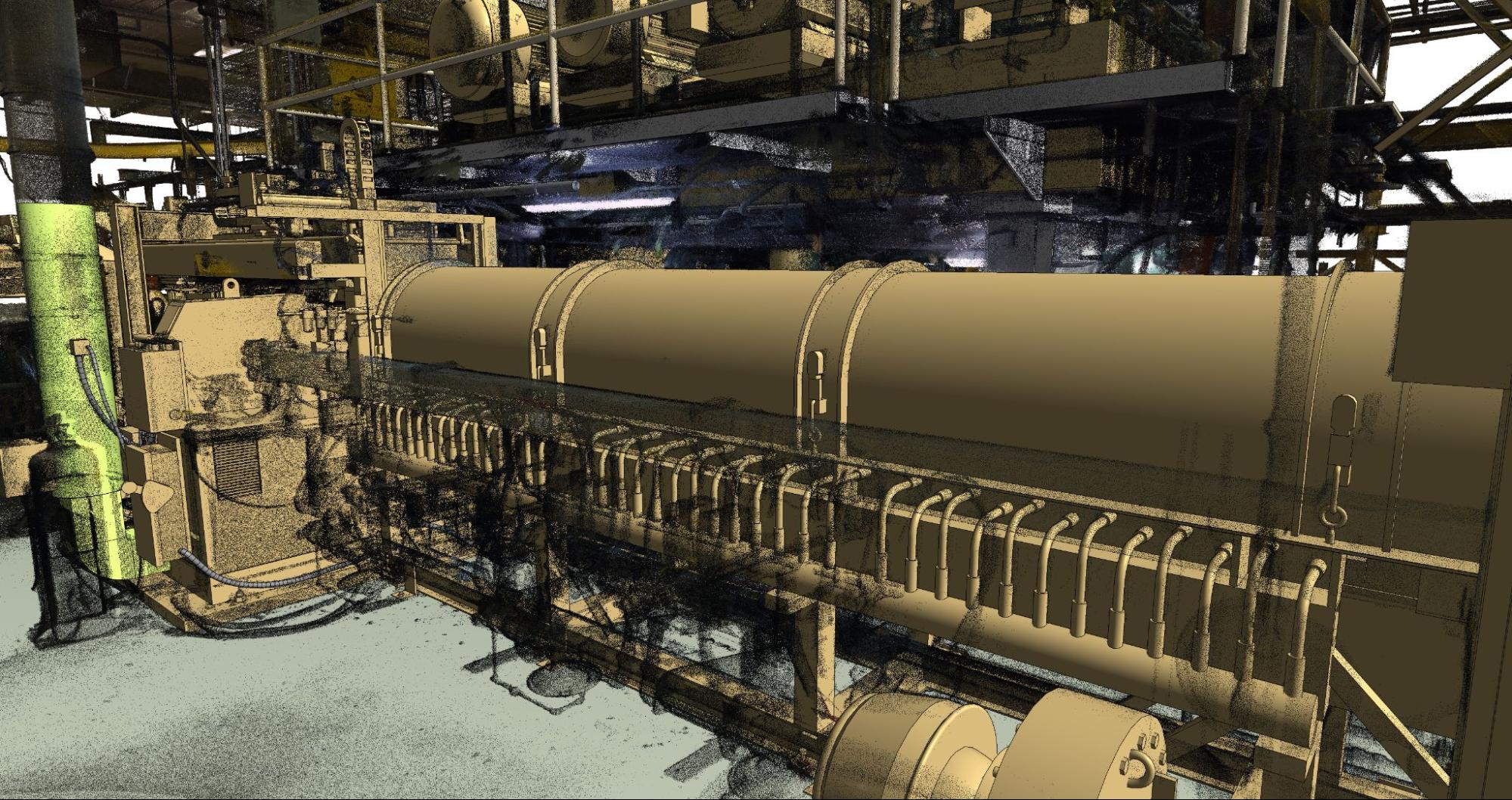

Project 758.US was an industrial factory project located in the United States, executed over a two-month period from April to June 2025. The facility, which consists of a single floor, covers a total area of 1,500m². Our specialists were responsible for the comprehensive Revit modeling of the facility’s architecture, structure, and MEP (Mechanical, Electrical, and Plumbing) systems, ensuring seamless integration and coordination between all disciplines. Working from Point Cloud data and reference images, the team developed a highly detailed as-built model with all disciplines delivered to a Level of Development (LOD) 400. A primary focus of this project was the meticulous modeling of large MEP objects, which involved capturing a high density of small, intricate components with precision.

| Client Profile | Confidential |

| Project Location | US |

| Industry | Factory / Industrial |

| Total Area | 1500m2 |

| No of floors | 1 Floor |

| LOD | LOD400 |

| Inputs | Point Cloud, Image |

| Deliverables | Revit File |

| Software Used | Revit, Navisworks, internal tools |

Business Needs

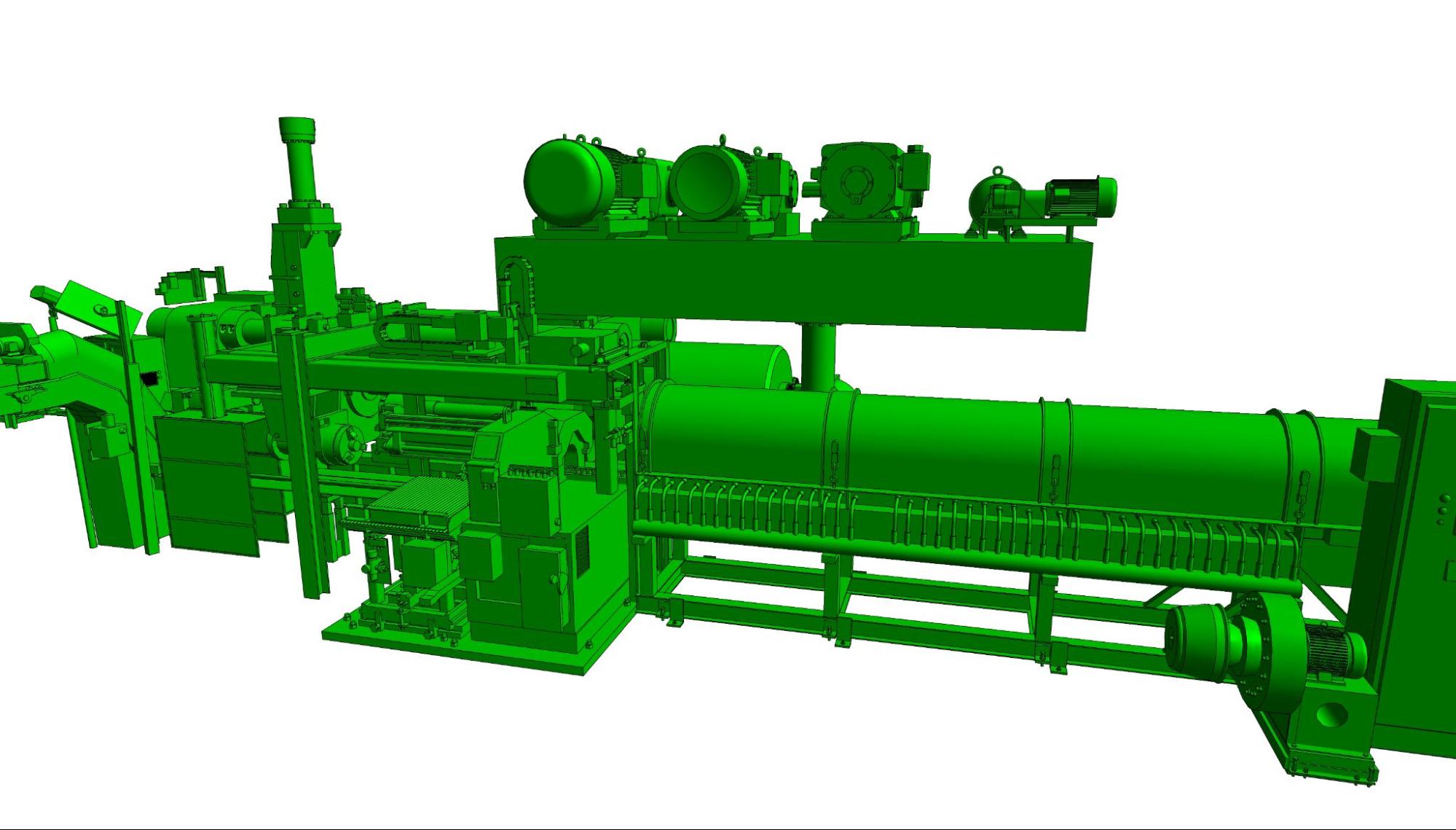

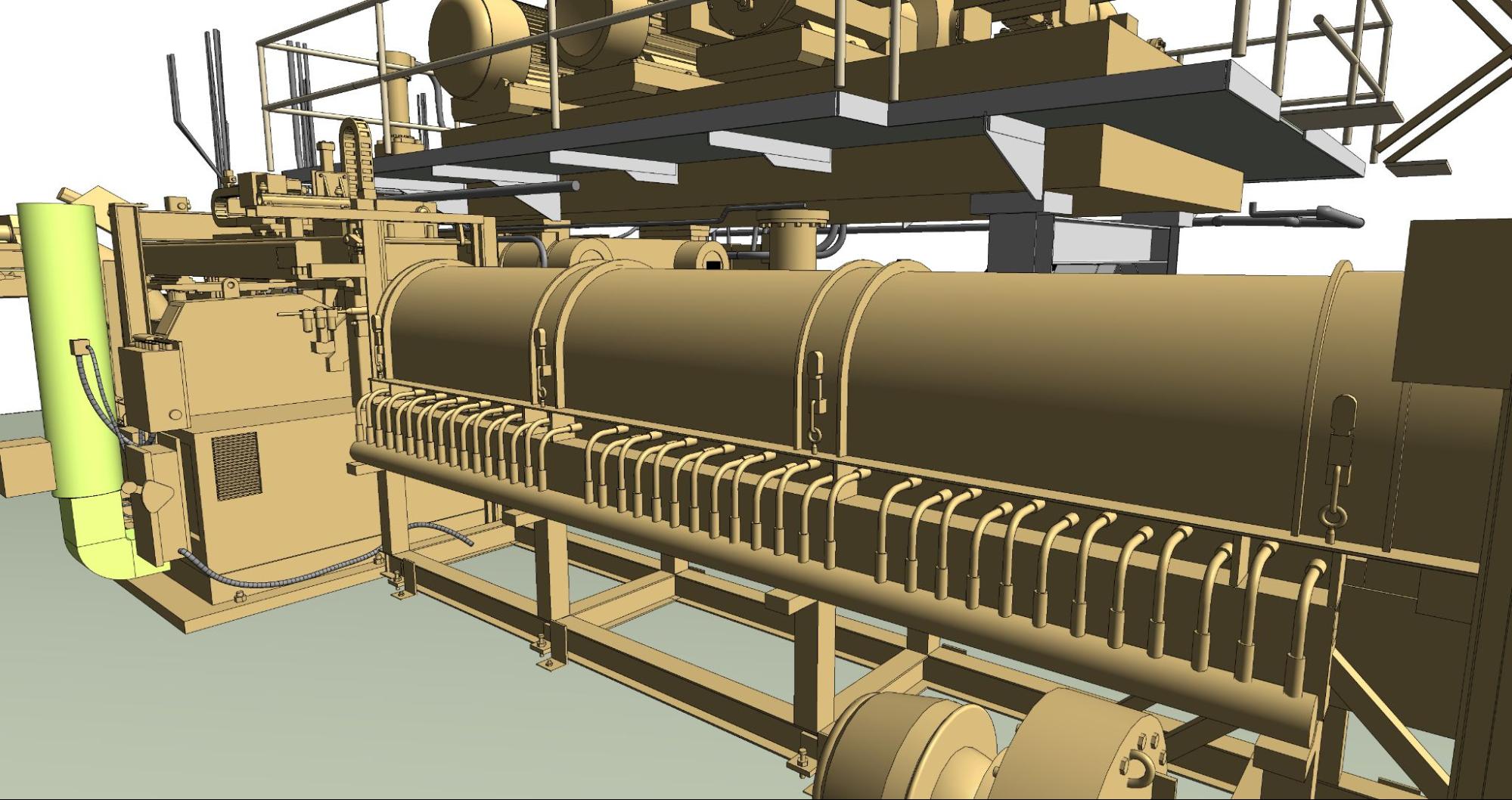

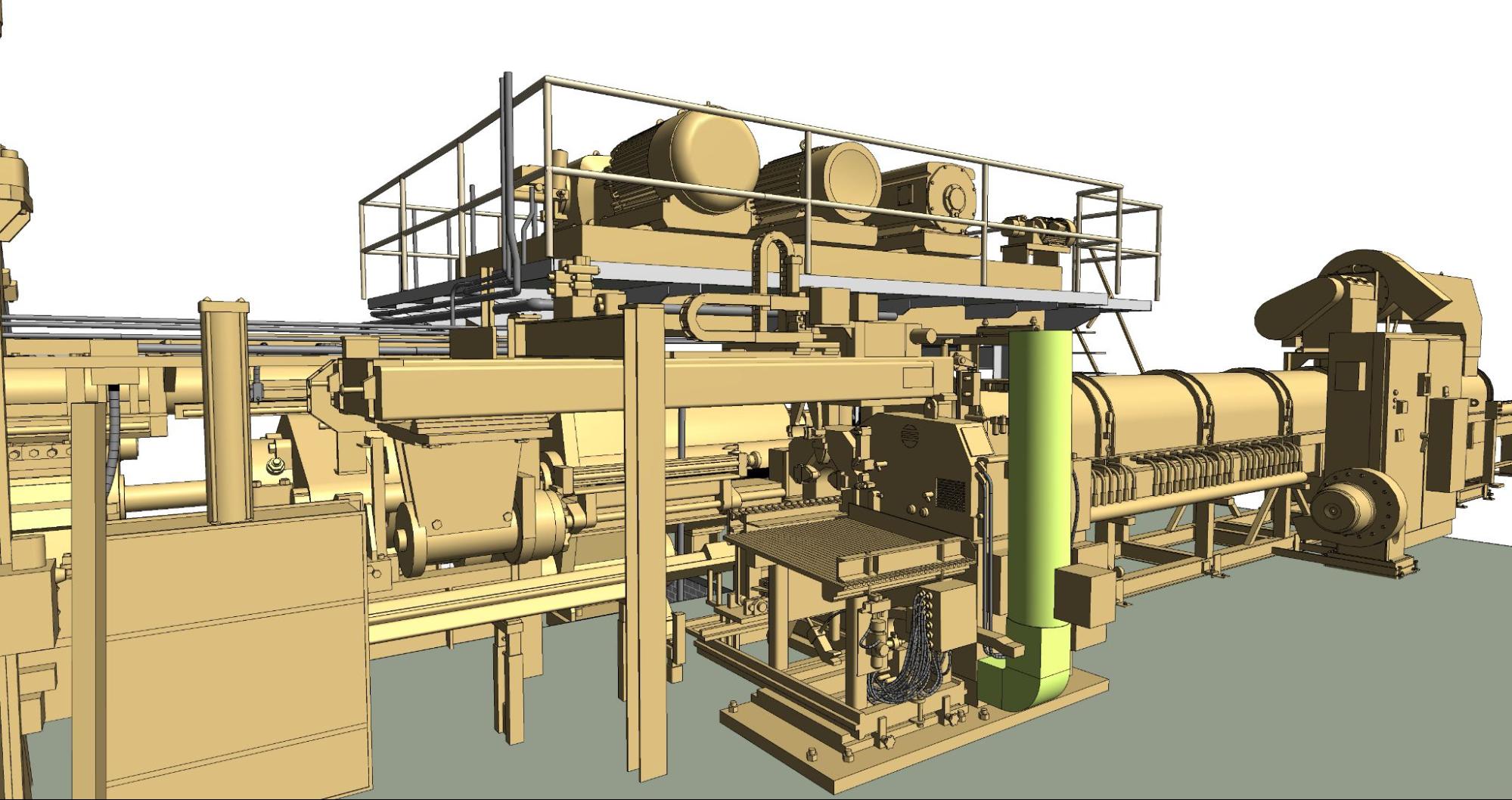

Project 758.US, a single-floor, 1,500m² industrial facility located in the United States, required a highly specific as-built model. The business need was to focus entirely on the aluminum extrusion press and its associated conveyor system, deliberately excluding surrounding structures or unrelated equipment. This required a meticulous approach to isolate and model the specified machinery with a high degree of precision, ensuring that the final deliverable was tailored to the client’s specific engineering and fabrication requirements.

Key Objectives

The main objective is to create a fabrication-ready 3D model with a required accuracy of ±0.25 inches at LOD 350, capturing all essential mechanical and structural details. The deliverables will support the fabrication and engineering processes, ensuring high precision for component integration.

Challenges

- Estimation: The estimation process was hindered by limited input information for the MEP discipline, which only included exterior images. This made it difficult to assess the internal space, as the images were not clear, and the modeling scope was not specifically defined. This project required a high level of detail for modeling the machinery.

- MEP Modeling: The poor quality of the Point Cloud data in areas with dense machinery made it difficult to accurately identify machine details and support racks. The system was installed as a complete operational unit, making the modeling of all objects within a single family result in large, time-consuming files. The aluminum extrusion press had equipment installed around it, with a complex and intertwined system of electrical conduits and flexible pipes. Exporting to a different software format required research and time to ensure no loss of display or object appearance.

- QA-QC: Effectively controlling the quantity and quality of MEP objects within the limited timeframe of the QA-QC process was a significant challenge.

Our Solutions and Approach

- Estimation: To overcome the limitations of the input data for the estimation, ViBIM used a method of cross-referencing with similar completed projects, combined with analyzing the specific characteristics of this project type and the density of the MEP system. Our extensive experience allowed us to provide an accurate time estimate for each item. We proposed that the client provide additional information related to the objects to be modeled.

- MEP Modeling: We combined the image data provided by the client, referencing it during the modeling process for speed and accuracy. Since modeling the entire machine block was cumbersome and difficult to control, we broke it down into smaller blocks such as the pulling motor, conveyor belt, and stamping machine block to perform the modeling. We researched and learned to ensure that exporting to another software format would not result in the loss or distortion of objects.

- QA-QC: To ensure the quality and quantity of MEP objects within the limited QA-QC time, ViBIM applied a multi-step inspection process, including section checks, Navisworks checks, and the use of a proprietary Point Cloud analysis solution.

- Revised after QC: To deliver the highest quality product, ViBIM committed to checking and correcting all errors pointed out by the client. In addition, we used our proprietary Point Cloud analysis solution to perform a final check before handover, ensuring the model file achieved the highest accuracy and reliability.

Business Impact

- Enhanced the quality and reliability of the MEP model: The MEP Modeling process was carried out by an experienced team (supervising new personnel), adhering to the allowable tolerance (+/- 15mm) and technical standards. The use of parametric families and in-house tools helped create a detailed and accurate model, minimizing potential errors and clashes, ensuring the quality of the delivered product.

- Ensured the highest quality of delivered products: A strict QA-QC process with multiple layers of inspection (Section, Navisworks, Point Cloud analysis tools) and the application of support tools helped ViBIM to thoroughly detect and fix errors before delivering the product to the client. This ensures the model file is of the best quality and meets the project’s requirements.

- Provided visual and valuable information for later stages of the project: The detailed BIM model provided by ViBIM is not only useful in the design and construction phases but also brings long-term value to the operation and maintenance stages. Accurate information about the location and technical specifications of MEP objects makes future management, maintenance, repair, and system upgrades easier and more efficient.