Revit Modeling for a US Factory with Dense MEP Systems

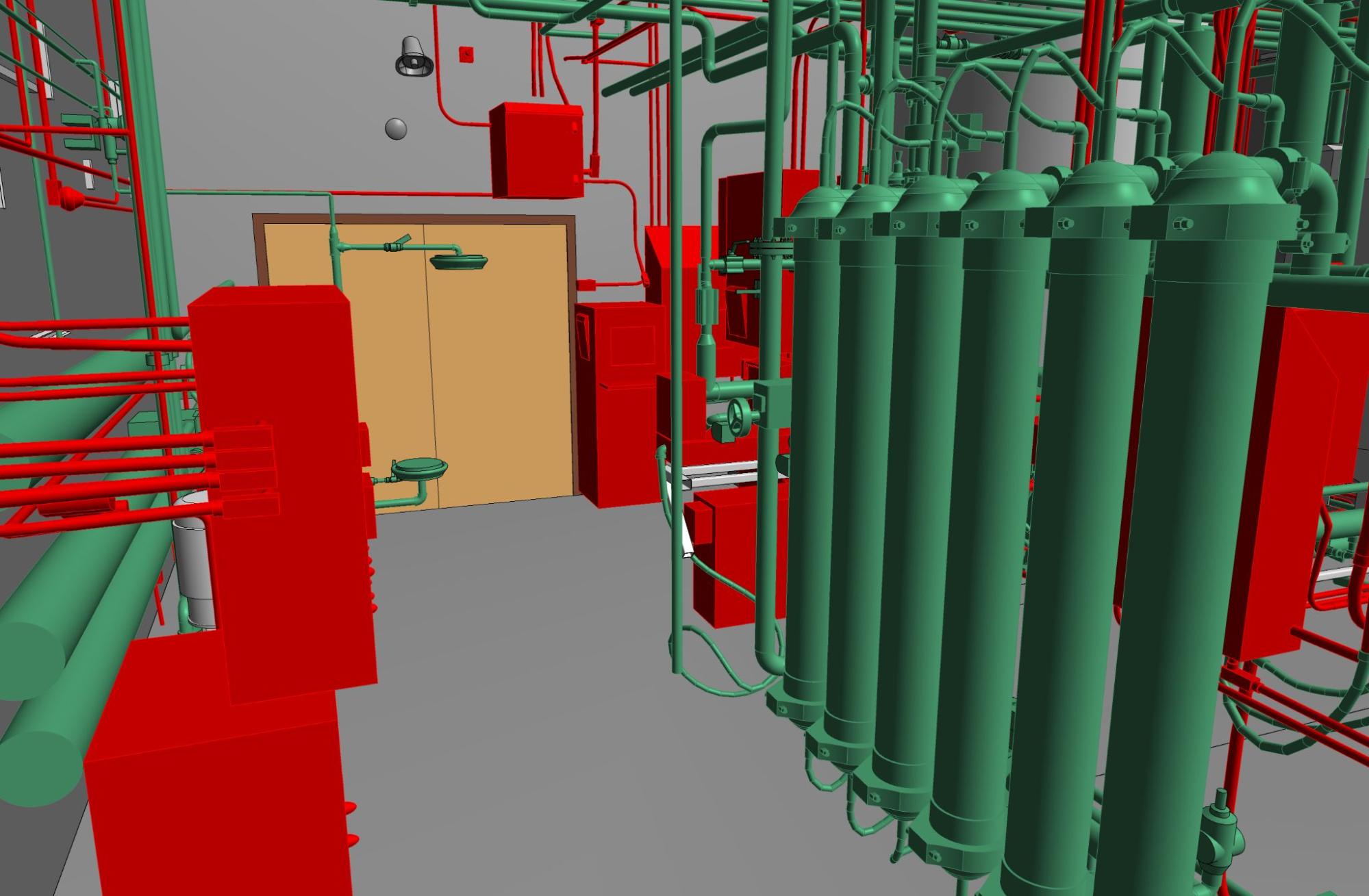

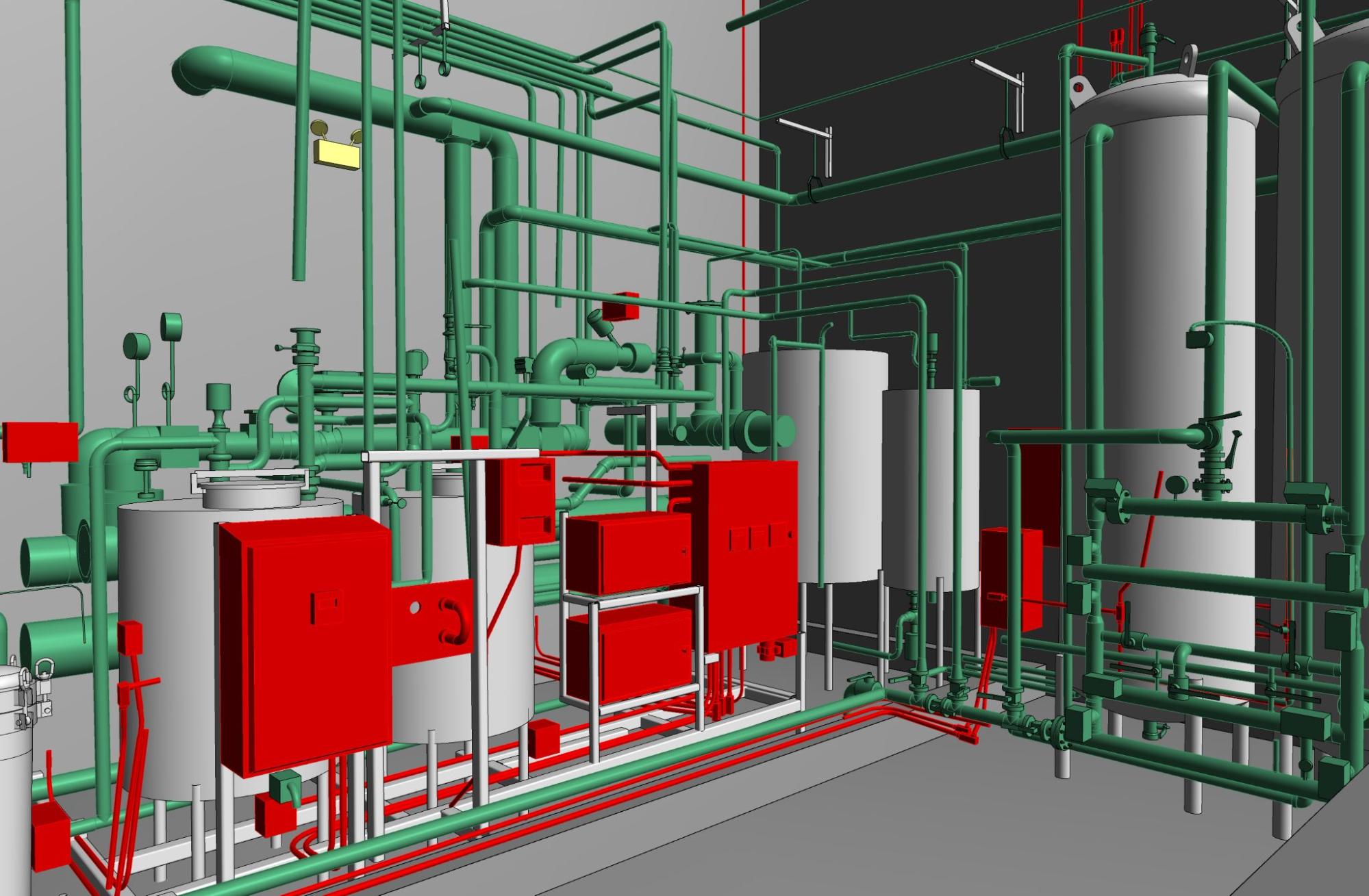

Project 508.US involved the comprehensive Scan to BIM modeling of a factory in the United States, executed over a two-month period from May to June 2023. The single-floor industrial facility spanned a total area of 800 m². The scope of work required our specialists to develop fully integrated Revit models encompassing all architectural, structural, and MEP (Mechanical, Electrical, and Plumbing) disciplines by transforming the raw point cloud data into an intelligent, as-built 3D environment. All elements were modeled to a precise Level of Detail (LOD) 300. A key highlight and significant challenge of this project was the successful modeling of its extremely dense MEP systems, which contained a high volume of small, intricate objects that were difficult to observe and accurately capture from the scan data alone.

| Client Profile | Confidential |

| Project Location | United States |

| Industry | Industrial / Factory |

| Total Area | 800m2 |

| No of floors | 1 Floor |

| LOD | LOD300 |

| Inputs | Point Cloud |

| Deliverables | Revit File |

| Software Used | Revit, Navisworks, internal tools |

Business Needs

The project, designated 508.US, involved the comprehensive modeling of a manufacturing facility located in the United States, spanning an approximate area of 800 m². The project’s scope was all-encompassing, requiring the development of a fully integrated 3D model that included all architectural, structural, and MEP (Mechanical, Electrical, and Plumbing) components. The primary business need was to convert raw point cloud data into a standardized, as-built 3D BIM model, with a particular focus on simulating the complete MEP systems to a high technical Level of Detail (LOD). This digital asset was intended to serve as a foundational tool for the facility’s ongoing management, operations, and maintenance cycles. The plant itself presented a complex environment, featuring a mix of large open-plan production spaces and distinct technical zones. These areas—including machine rooms, workshops, and technical corridors—were further complicated by exposed structural steel beams and equipment distributed at varying elevations, directly influencing the layout and routing strategy for the dense MEP systems.

Key Objectives

The principal goals for this Scan to BIM project were defined with a focus on precision and long-term usability:

- Comprehensive MEP System Modeling: To create a detailed digital representation of all Mechanical, Electrical, and Plumbing systems, including HVAC, Plumbing, Fire Fighting, Electrical, and Communication networks.

- Accurate Equipment Classification: To precisely classify and model all major M&E equipment, ensuring that each component in the Revit model was embedded with its correct technical specifications and asset data.

- Creation of a Connected As-Built Model: To develop a fully connected digital model where all systems are logically linked, accurately reflecting the true on-site conditions and strictly adhering to the technical standards provided by the client.

Challenges

Modeling the dense MEP systems from point cloud data, particularly within a freshwater treatment machine room, presented a unique set of technical challenges:

- High Density and Complexity of MEP Systems: The confined machine room was intricately packed with a vast network of pipes, valves, pumps, and sensors. This resulted in an exceptionally dense and overlapping point cloud, making the clear identification and isolation of individual components extremely difficult.

- Point Cloud Data Quality and Integrity: The physical environment, characterized by high humidity, poor lighting, and reflective metallic surfaces, impacted the quality of the laser scans. This introduced data noise and occlusions, necessitating a more rigorous and meticulous point cloud processing and cleanup phase.

- Difficulty in Object Differentiation: Given the high density of the point cloud, accurately distinguishing between different elements—such as pipes versus conduits or identifying specific valve types—was a significant hurdle that required advanced modeling techniques and deep domain expertise.

- Stringent Accuracy Requirements: The project demanded an extremely high degree of precision, as even a minor inaccuracy in the position or dimension of a pipe could lead to critical installation failures or clashes during future renovation work.

- Resource-Intensive Process: The manual conversion of such a complex point cloud into an intelligent BIM model is inherently time-consuming, posing challenges to the project timeline and requiring significant investment in high-performance hardware and specialized personnel.

- Lack of Non-Geometric Data: A point cloud provides only physical geometry. To create a BIM model truly valuable for facility management, our team had to source and integrate non-graphical information (e.g., manufacturer data, model numbers, capacity) for key equipment.

- Large-Scale Data Management: The sheer volume of the point cloud data required a robust IT infrastructure and efficient data management software to handle processing without performance degradation.

Our Solutions and Approach

To overcome these challenges and deliver a superior-quality model, ViBIM implemented a multi-faceted strategy combining a structured workflow with advanced resource management. How did we ensure precision in such a complex environment?

- Standardized Workflow and Rigorous Quality Control:

- Modular Modeling: We adopted a modular approach, strategically dividing the complex machine room into smaller, manageable zones. Each module was modeled independently before being integrated into the master model. This method simplified complexity, enabled efficient task delegation, and streamlined quality control for each section.

- Continuous Clash Detection: Automated interference checks were run frequently throughout the modeling process using Navisworks. This allowed us to identify and resolve conflicts between MEP systems and structural elements at the earliest possible stage, preventing costly rework.

- Accuracy Validation: Upon completion, we conducted a thorough accuracy assessment by overlaying the final BIM model against the original point cloud data. This validation process allowed us to quantify and verify the model’s geometric fidelity and ensure it met the client’s stringent precision requirements.

- Enhanced Team Capabilities and Resource Management:

- Specialized Training: Our team of BIM and MEP engineers utilized their specialized training in advanced point cloud processing, complex MEP modeling, and automation tools to enhance both speed and accuracy.

- High-Performance Hardware: We leveraged a high-performance hardware infrastructure to efficiently process the large point cloud files and complex BIM models, which minimized latency and maximized the productivity of our modeling team.

- Centralized Data Management: A collaborative, server based platform was used for the secure storage, sharing, and version control of all project files, ensuring seamless information flow and consistency among all team members.

- Dedicated Manpower: To meet the project’s demanding schedule, we dedicated a significant concentration of our most skilled personnel, ensuring sufficient resources were available to complete all tasks within the required timeframe without compromising quality.

Business Impact

By successfully transforming the complex point cloud data into an intelligent and accurate Revit model, ViBIM delivered significant value and tangible benefits to the client.

- Minimized On-Site Risk and Rework: The client received a highly accurate as-built model that enabled the detection and resolution of all potential clashes before any physical renovation commenced. This proactively eliminates the risk of costly demolition, on-site repairs, and disruptive schedule delays.

- Optimized Operations and Maintenance (O&M): The BIM model now serves as an intelligent asset management database. It contains detailed information for every MEP component, allowing facility managers to easily access technical specifications, maintenance history, and precise locations for streamlined asset tracking and proactive maintenance scheduling.

- Simplified Maintenance and Repairs: With the detailed 3D model, maintenance staff can quickly and accurately locate components needing inspection or repair, even in congested and hard-to-reach spaces, improving safety and efficiency.

- Reduced Unforeseen Costs: By eliminating design errors and clashes early in the digital phase, the model significantly reduces the emergent costs typically associated with rework, change orders, and on-site modifications during the building’s lifecycle.