Business Needs

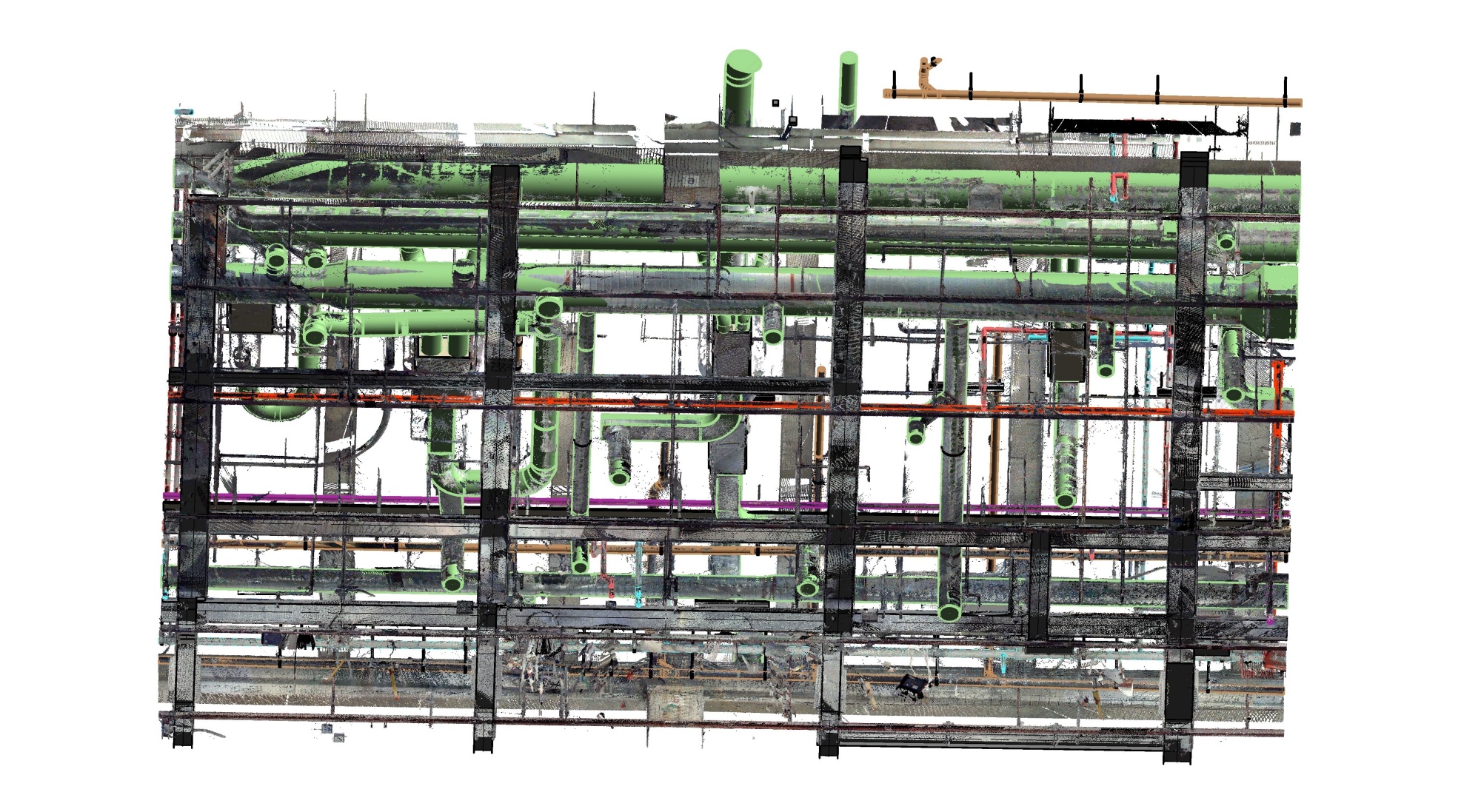

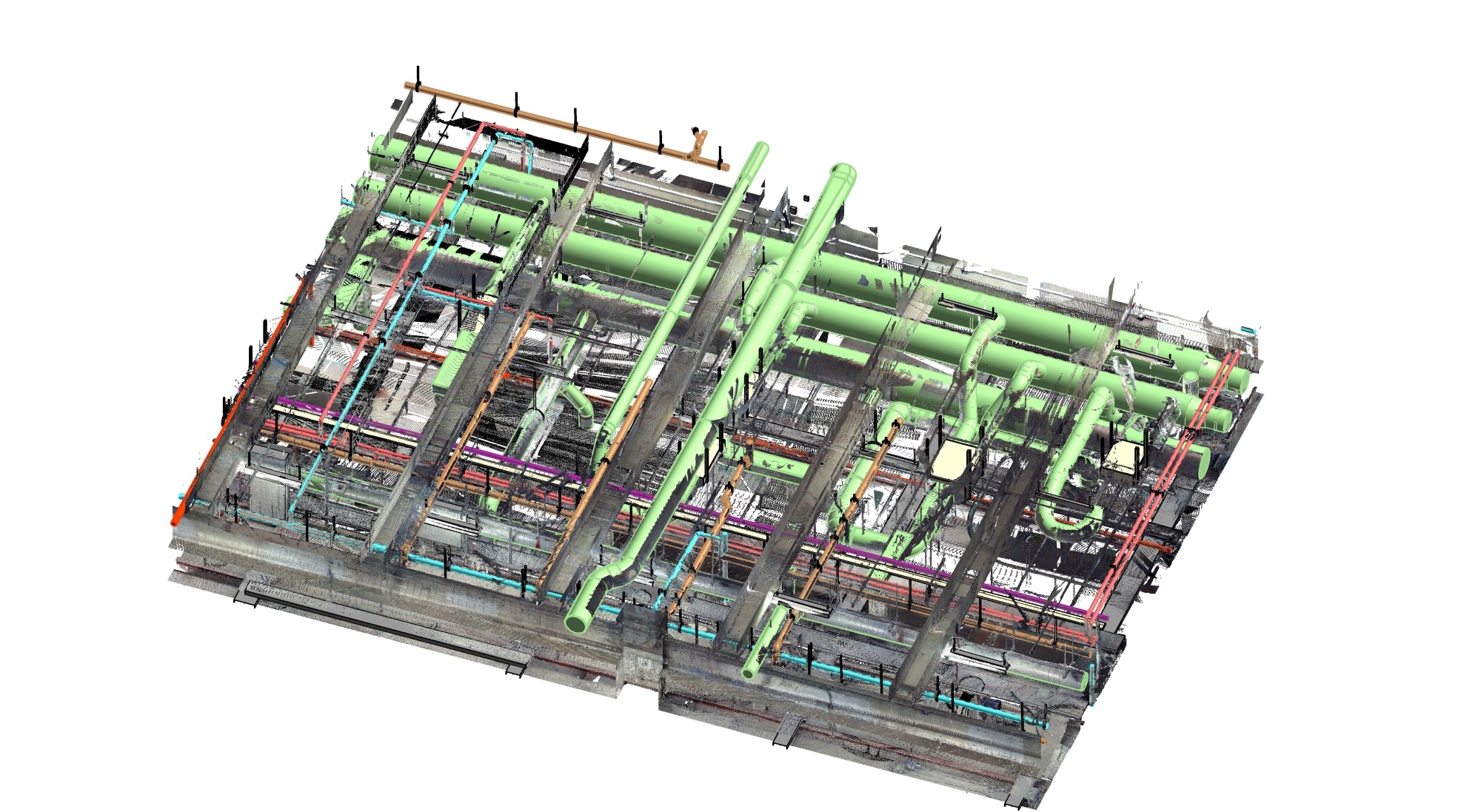

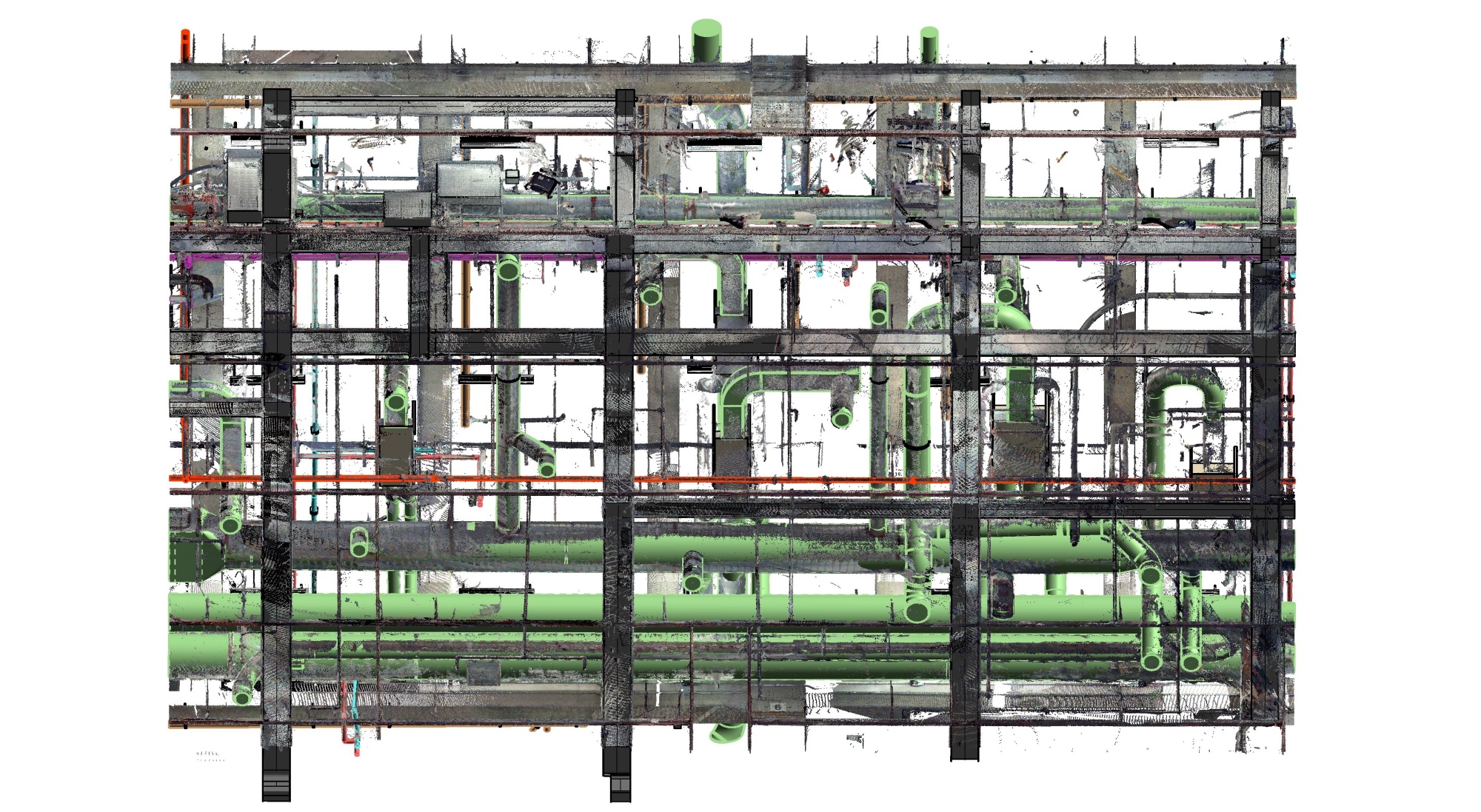

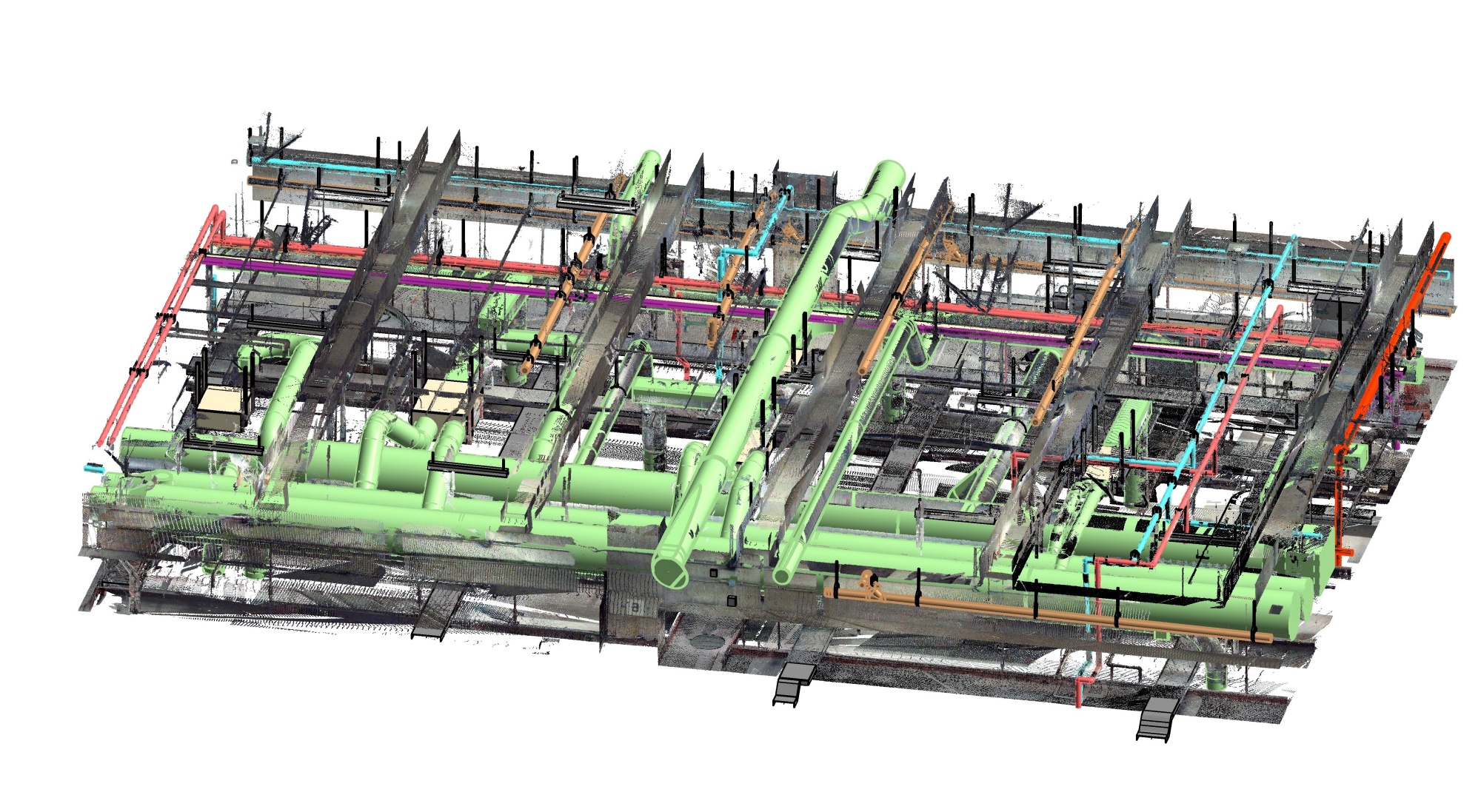

“311.Canada Hospital” is a partial modeling project of a hospital complex located in Canada, covering an area of approximately 10,000 m² and spanning three floors. The scope focuses on detailed modeling of architectural base elements and primarily the Mechanical, Electrical, and Plumbing (MEP) systems to support effective and accurate management, renovation, and operation of the hospital’s technical infrastructure.

Key Objectives

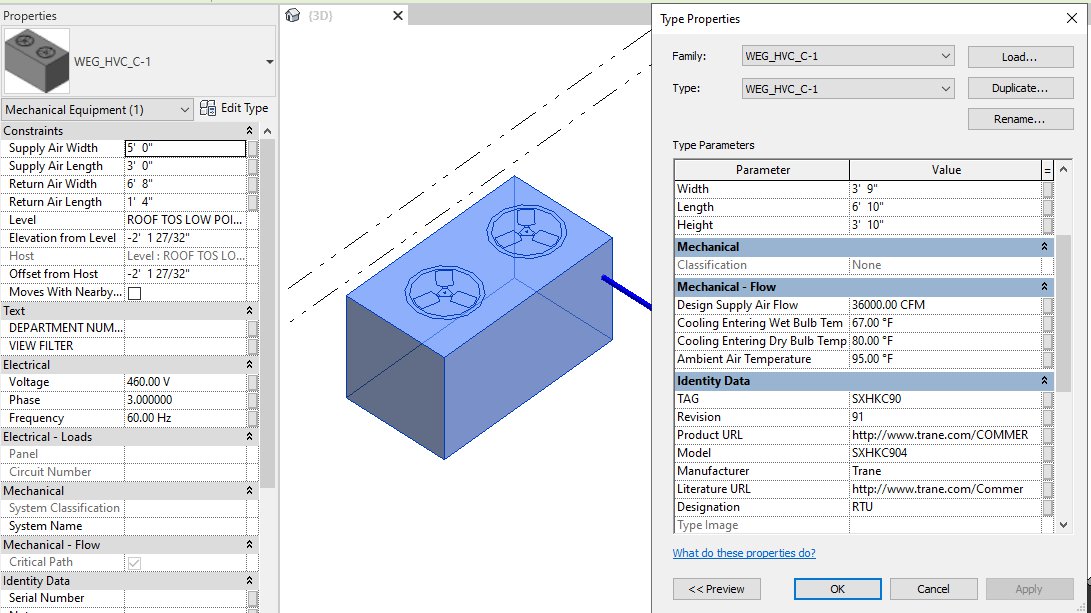

Develop a highly accurate MEP model of components through scan to bim modeling services, enabling comparison between the Record Model and as-built conditions for asset maintenance and preservation.

- Estimate: Achieve a high-accuracy project schedule estimate closely aligned with actual man-hours required.

- MEP Modeling: Execute comprehensive modeling of all MEP disciplines ensuring deviation does not exceed ±15mm, strictly adhering to actual construction details and specifications.

- QA-QC: Establish rigorous Quality Assurance and Quality Control (QA-QC) processes to maintain high standards throughout inspection and correction phases, aiming for optimal deliverables before client handover.

- Revised after QC: Confirm and ensure all issues identified during QA-QC are fully resolved, producing a complete model that accurately reflects the existing MEP system conditions.

- Added Value: Provide a reliable model foundation for future design, renovation, or facility management stages, improving asset management and operational efficiency.

Challenges

- Estimate: Estimation efforts were challenged by limited input data for MEP disciplines, confined to PDF documents and exterior photographs, complicating internal space assessment, suspended ceiling locations, object density, number of service shafts, and system layout.

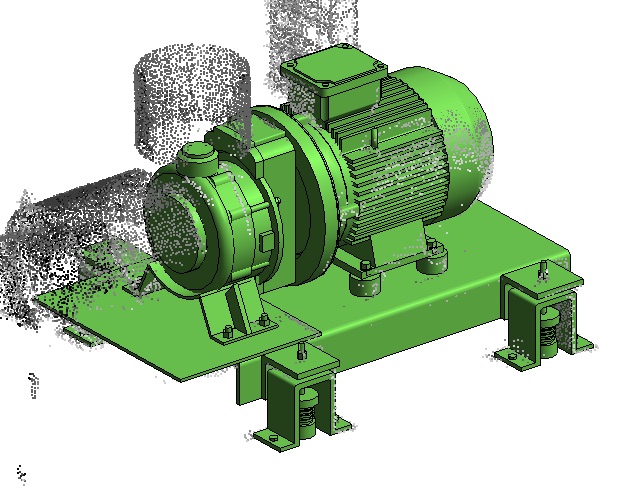

- MEP Modeling: The project features dense, complex, and overlapping MEP elements, complicating classification and accurate modeling. Systems such as HVAC, fire protection, potable and wastewater, conduits, cable trays, medical gas, and suction/pressure frequently overlap in technical shafts, equipment rooms, basements, and corridor ceilings.

- Ensuring correct system classification (e.g., conduits must not be modeled as pipes or ducts) is challenging due to high object density.

- The hospital’s critical ventilation system posed difficulties in accurately identifying system types and existing plumbing systems. Detailed ventilation modeling was complicated by Point Cloud data covering the entire exposed ceiling system, creating a dense object environment and time-consuming process. To accelerate progress and align with scan data, creating specialized Family Duct Fittings for bends and transitions was essential.

- Dense MEP object clusters in complex areas combined with Point Cloud quality may limit identification and precise modeling within tight schedules.

- QA-QC: Efficient control of MEP quantity and quality within restricted QA-QC timeframes required optimized workflows.

- Revised after QC: Controlling and correcting all identified and potential errors to deliver an optimal quality product was a key goal.

Our Solutions and Approach

- Efficient Visualization Management in Dense Object Environments: To work effectively within high-density MEP areas, ViBIM applied model segmentation by zones and used sectional and elevation views for each specific area. This approach provides clearer visualization of object locations and shapes, minimizing confusion and enhancing accuracy. Navisworks Clash Detection was utilized to identify and resolve system conflicts at the earliest stage.

- Enhancing Object Identification: Practical expertise is vital for accurate MEP element recognition. ViBIM’s experienced MEP team, skilled in each system discipline, continually trains on the latest tools and workflows to improve recognition and handling of complex cases.

- Ventilation System Identification: For ventilation modeling, ViBIM combined analysis of as-built photographs with Leica Trueview annotations. This method enabled precise labeling and information attachment, ensuring the model correctly represents the existing ventilation system type.

- Plumbing System Modeling: Provided with detailed 2D drawings for plumbing, modelers adhered strictly to these documents to accurately construct each piping route, ensuring logical consistency and design compliance.

Business Impact

- Effective Asset Management and Simplified Maintenance: Precisely labeled assets in the BIM model facilitate systematic and efficient maintenance operations.

- Accurate System Information Reducing Field Surveys: Key systems are accurately located and classified, reflecting true conditions even in confined spaces, significantly reducing on-site survey time.

- Ensured Quality and Reliability of MEP Models: Modeling executed by professional teams complies with tolerance and technical standards, employing intelligent tools and libraries to ensure detailed, accurate models that minimize conflicts.

- Optimized Coordination and Team Efficiency: ViBIM emphasizes clear communication and aligned workflows, leveraging Revit and Navisworks to enhance inter-disciplinary coordination and accelerate project delivery.

- Commitment to Highest Quality Deliverables: Strict QA-QC procedures with multiple inspection layers and supporting tools guarantee that all issues are detected and resolved before delivering premium quality models to clients.

- Providing Valuable Information Foundation for Future Stages: The detailed BIM model not only serves current project needs but also acts as a reliable visual and data resource for future operation, maintenance, repair, and upgrade phases, optimizing asset management and facility operations.

See how our expertise handles even the most dense and complex environments. Our 3D BIM Modeling Services provide the clarity and accuracy your project demands, from initial scan to final deliverable.