Business Needs

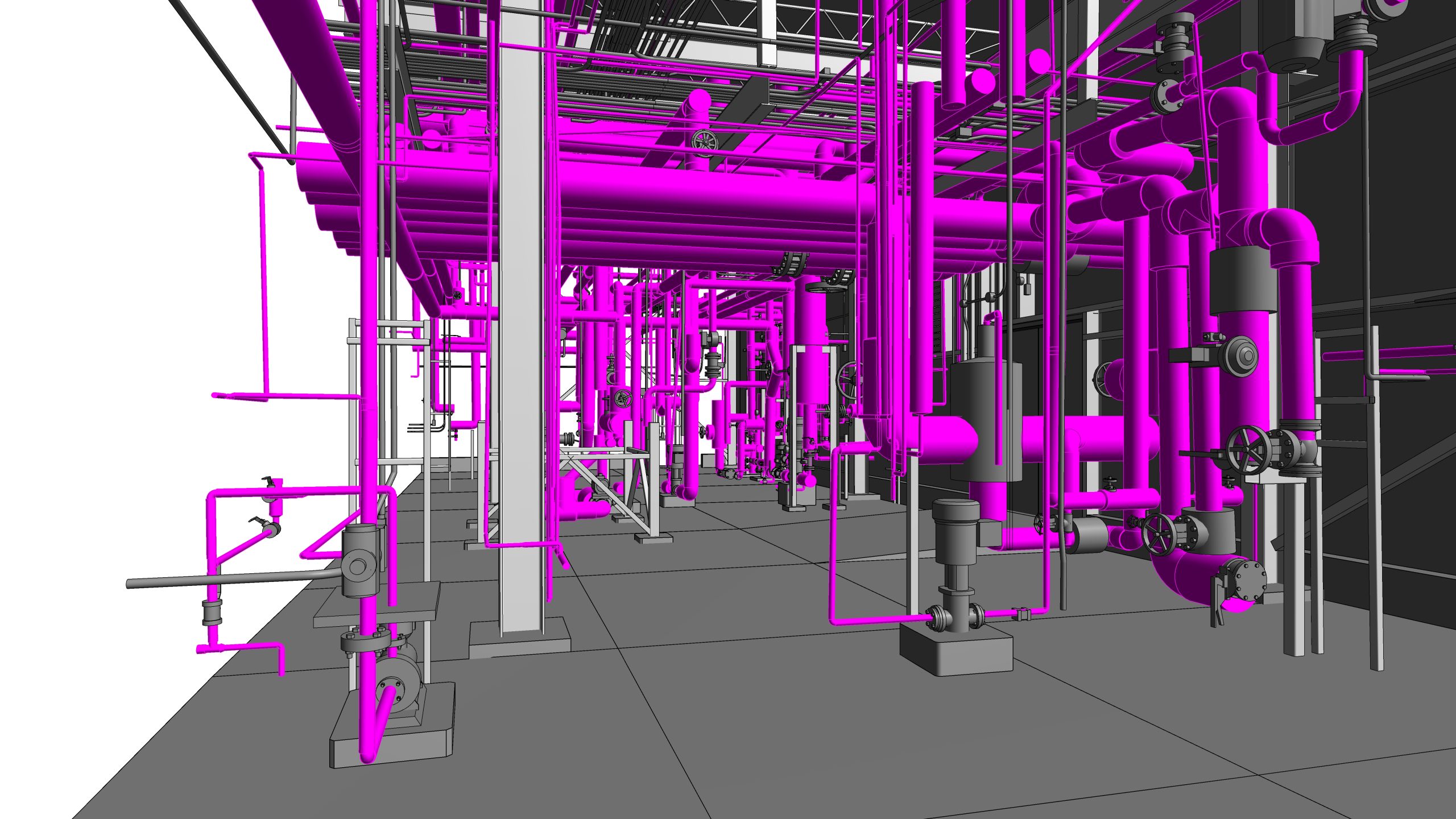

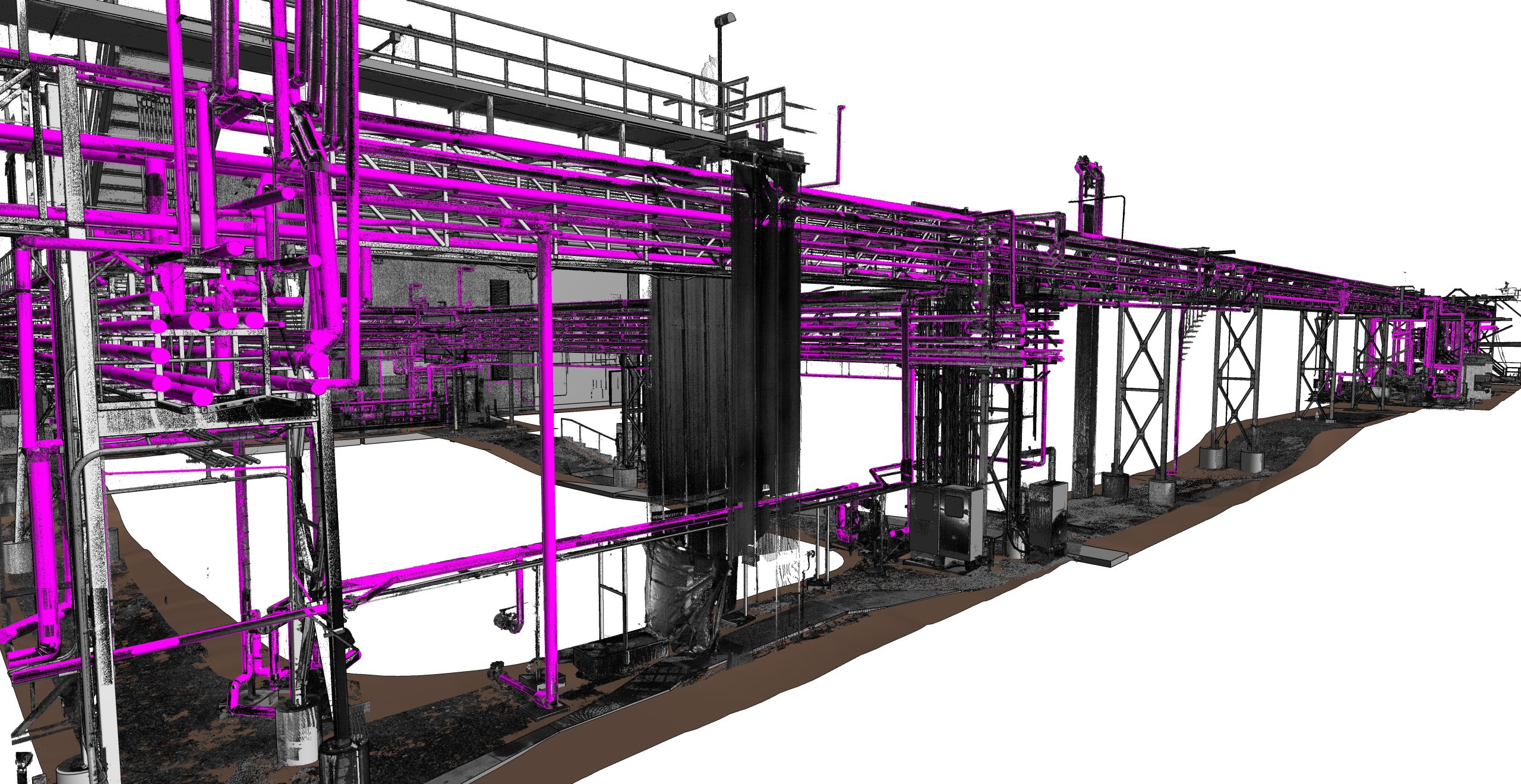

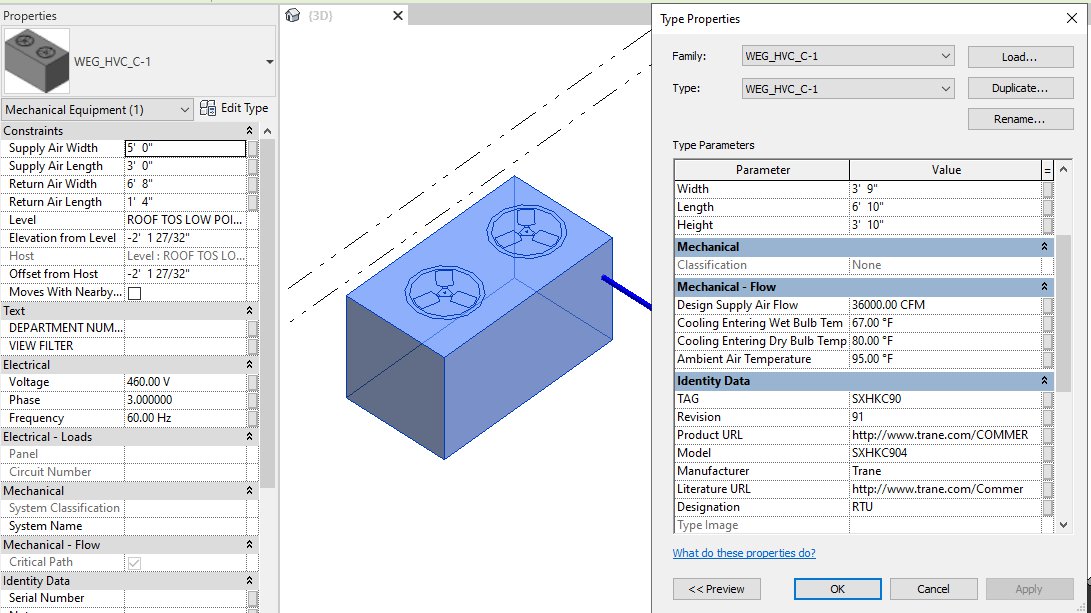

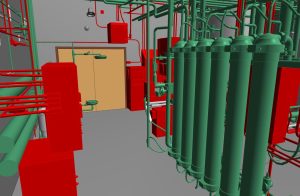

Project 491.US involved the intricate task of creating a comprehensive as-built model for an existing industrial plant in the United States, a facility covering an extensive area of approximately 1,800m². The project’s scope was all-encompassing, requiring the detailed modeling of all Architectural, Structural, and MEP (Mechanical, Electrical, and Plumbing) components from raw point cloud data. The central business need was to develop a highly accurate, integrated BIM model that could serve as a reliable foundation for ongoing facility management and operational tasks. A critical requirement was to ensure that all mechanical and electrical systems, along with their associated equipment, were modeled with a technical Level of Detail (LOD), capturing not just geometry but also essential data for maintenance and analysis. The facility itself, characterized by complex machine rooms and a vast network of pipelines connecting different operational zones, demanded a solution that could deliver clarity and precision in a congested environment.

Key Objectives

- Facilitate Renovation and Retrofitting: To generate an accurate 3D as-built model from point cloud data that would serve as a reliable baseline for planning and executing future renovation projects.

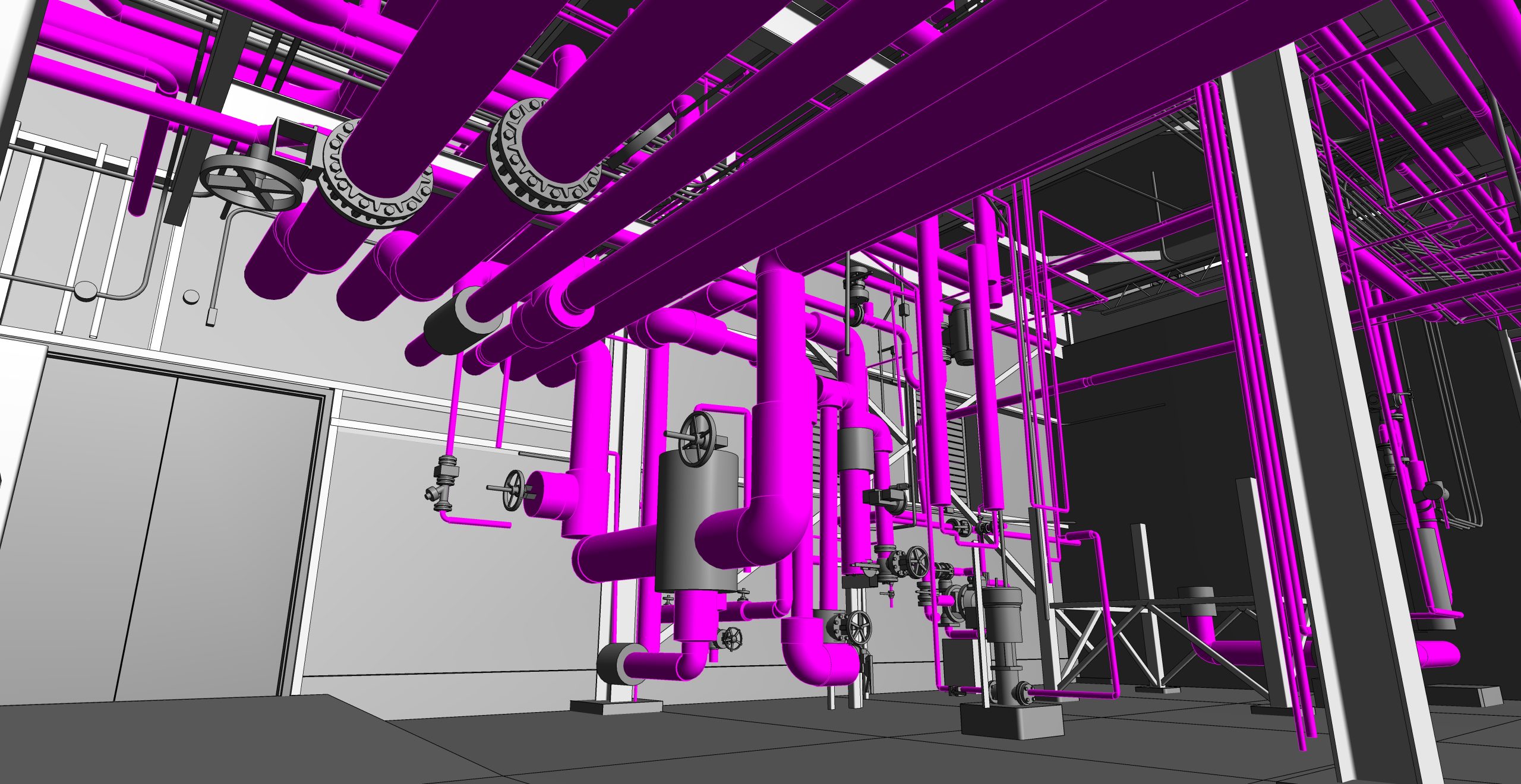

- Develop a Comprehensive MEP Model: To construct a detailed model of all MEP disciplines, ensuring every component—including equipment, water pipes, cable trays, and electrical conduits—adhered strictly to technical standards, manufacturer specifications, and the physical construction of the elements. The resulting model was required to accurately reflect all design parameters to enable seamless coordination between architectural, structural, and MEP teams.

- Enhance Operational Safety and Compliance: To produce a clear and precise digital map of the plant’s complex and frequently modified MEP systems. Given the critical nature of gas, chemical, and high-power electrical conduits, an accurate model was paramount for ensuring worker safety, streamlining maintenance protocols, and maintaining strict compliance with industrial regulations.

Challenges

- High Density of MEP Components: The technical areas, machine rooms, and transformer stations featured an exceptionally high concentration of equipment, piping, and electrical cabling. This density created significant data occlusion and noise in the point cloud scans, presenting a substantial challenge for modelers to accurately interpret and reconstruct the as-built conditions without gaps or errors.

- Requirement for Precise Connection Modeling: In an industrial environment, modeling goes beyond individual assets; it requires an exact representation of the physical and logical connections between them. Accurately modeling pipe fittings, valve connections, electrical terminations, and control system links was critical. Any imprecision in these connections could severely impact the validity of designs for future expansion or interfere with crucial analyses of energy distribution and fluid dynamics.

Our Solutions and Approach

How does a team transform a dense and noisy point cloud into a pristine, functional BIM model? At ViBIM, our approach combines advanced technology with deep domain expertise to overcome such challenges methodically.

- Systematic Deconstruction and Phased Modeling: To manage the project’s complexity, we divided the plant into smaller, manageable zones, allowing for meticulous quality control at each stage. Our modelers expertly navigated the point cloud data—utilizing sectioning, layering, and element isolation techniques—to gain clear views of obscured objects. The modeling process was strategically initiated with larger, more defined MEP components like main pipelines and primary equipment. These elements formed a structural backbone, which we then progressively populated with smaller, more densely packed components, ensuring a logical and accurate build-up.

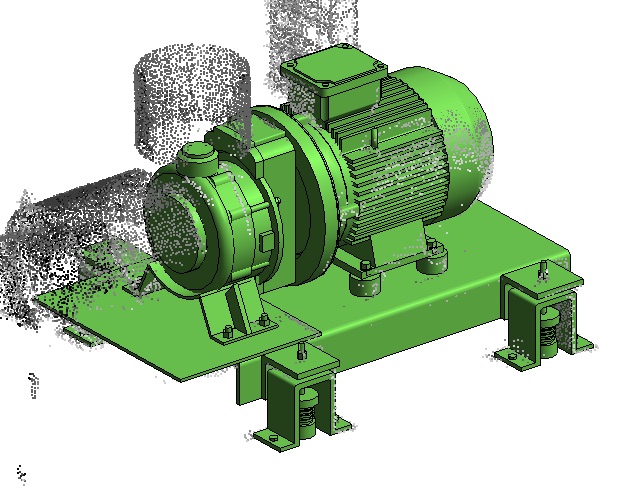

- Expert Interpretation and Feature Recognition: Even the most advanced scanning can produce noisy or incomplete data. Our team’s strength lies in its experience and ability to “read” the point cloud. Modelers leveraged their deep understanding of MEP systems to recognize the fundamental shapes (circular, square, rectangular) and characteristic features of different components, accurately identifying and modeling elements even where data was partially obscured.

- Advanced Visualization and Data Enhancement: To improve the clarity of the raw data, we employed advanced visualization techniques within our software environment. By adjusting the point cloud display, applying RGB color modes, and enhancing contrast levels, we were able to accentuate the edges and surfaces of pipes, cables, and equipment. This technical enhancement made it significantly easier to distinguish individual components from the surrounding clutter.

- Prioritization of Critical Connections: Recognizing that system functionality is defined by its connections, we placed a special emphasis on modeling these points with the highest degree of accuracy. Our team meticulously detailed the intersections between equipment, pipelines, and electrical systems, ensuring that every flange, valve, and junction was correctly represented. This focus guarantees the model is not just a geometric replica but a functional digital twin.

Business Impact

The implementation of ViBIM’s work as a leading Scan to BIM Service Provider delivered tangible, long-term value to the client, transforming their facility management and operational capabilities.

- Creation of a Centralized Digital Asset Database: The project delivered a comprehensive 3D digital database of the entire plant’s MEP system. This allows the asset management team to instantly access detailed information for every component, including maintenance history and estimated lifecycle, enabling more strategic and data-driven decisions on maintenance scheduling and capital investments.

- Accelerated Maintenance and Reduced Downtime: With an intuitive and accurate 3D model, maintenance technicians can now rapidly and precisely locate any equipment, valve, or connection point requiring attention. This visual accessibility drastically reduces troubleshooting and repair times, minimizing production downtime and optimizing overall maintenance expenditures.

This is how we bring clarity to the most complex industrial environments. See why clients choose us as their trusted Revit BIM Modeling Service Provider for projects where precision is non-negotiable.